What are the Advantages of Using Hydraulic Pumps and Motors

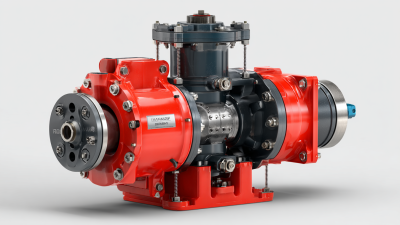

Hydraulic pumps and motors are integral components in various industrial applications, offering robust performance and efficiency. According to a recent market analysis report by Research and Markets, the global hydraulic pumps market is projected to reach USD 15.85 billion by 2026, growing at a CAGR of 3.5% from 2021, reflecting the increasing demand in sectors such as construction, agriculture, and manufacturing. These components are celebrated for their ability to transmit power efficiently, provide adjustable speed and torque, and facilitate precise control in hydraulic systems.

By harnessing the capabilities of hydraulic pumps and motors, industries can achieve enhanced productivity, reduced maintenance costs, and improved energy consumption, positioning these hydraulic solutions as pivotal in modern engineering and machinery design.

As technology advances, the potential for further innovation in hydraulic systems promises even greater benefits and efficiencies for users across various fields.

Benefits of Hydraulic Pumps in Industrial Applications

Hydraulic pumps play a crucial role in various industrial applications, offering significant benefits that enhance performance and efficiency. The increasing adoption of hydrostatic transmissions in mobile equipment showcases these advantages, as they provide improved power delivery and adaptability in different operational scenarios. With advancements in technology, such as the integration of sensors for predictive maintenance, industries can now minimize unplanned downtime and improve overall productivity.

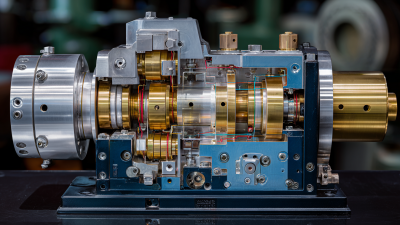

Moreover, innovations in hydraulic pump design, such as the development of variable displacement piston pumps, address the industry's demand for quieter and more efficient hydraulic systems. The evolution of hydraulic fluids is also notable, with a focus on formulations that enhance performance while reducing environmental impact. As companies continue to embrace smart hydraulic systems, they are better positioned to optimize energy consumption and achieve sustainability goals in industrial applications.

Enhanced Efficiency Through Hydraulic Motors

Hydraulic motors are renowned for their enhanced efficiency, making them a preferred choice in various industrial applications. One of the primary advantages of hydraulic motors is their ability to convert fluid power into mechanical energy with minimal energy loss. This conversion is achieved through the design of the motor, which optimizes the use of hydraulic fluid to generate and control torque and speed. As a result, hydraulic motors can operate effectively under high loads, providing superior performance compared to electric or pneumatic alternatives.

Additionally, the flexibility and versatility of hydraulic motors contribute significantly to their efficiency. They can be seamlessly integrated into different systems, allowing for precise control over power delivery and speed regulation. This adaptability ensures that hydraulic motors can meet diverse operational requirements across industries, from construction and manufacturing to agriculture. As a result, businesses benefit from increased productivity and reduced energy consumption, ultimately leading to long-term cost savings and improved operational sustainability.

Advantages of Using Hydraulic Pumps and Motors

The bar chart above illustrates the key advantages of hydraulic pumps and motors, highlighting their enhanced efficiency in various operational aspects such as torque, size, speed, energy efficiency, and durability.

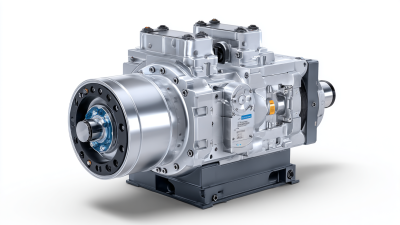

Increased Power-to-Weight Ratio of Hydraulic Systems

Hydraulic systems are renowned for their impressive power-to-weight ratio, making them a preferred choice in various industrial applications. According to a report by the International Journal of Hydraulic Engineering, hydraulic pumps and motors can generate significantly more force compared to their electric counterparts when weight is taken into consideration. This efficiency is primarily due to the dense nature of hydraulic fluid, allowing hydraulic systems to produce high torque and power without adding excessive weight to the machinery.

For instance, research indicates that hydraulic motors can achieve power outputs of up to 80 horsepower per unit weight, which is approximately 30% higher than similar electric motor systems. This enhanced efficiency not only contributes to better performance but also supports reduced energy consumption and lower operational costs. Moreover, the compact design of hydraulic components enables manufacturers to create smaller, lighter equipment without sacrificing the necessary power, which is invaluable in construction, aerospace, and mobile machinery sectors. As industries continue to prioritize efficiency and performance, the advantages of hydraulic systems will remain a critical consideration in engineering and design.

What are the Advantages of Using Hydraulic Pumps and Motors - Increased Power-to-Weight Ratio of Hydraulic Systems

| Feature |

Hydraulic Pumps |

Hydraulic Motors |

Benefits |

| Power Output |

High |

Moderate |

Efficient power transfer |

| Weight |

Lightweight |

Compact |

Reduced overall system weight |

| Efficiency |

High efficiency at various loads |

Variable speed tuning |

Versatile performance |

| Response Time |

Quick |

Fast |

Immediate system response |

| Durability |

Long lifespan |

Robust |

Reliable under tough conditions |

Versatility of Hydraulic Pumps in Various Environments

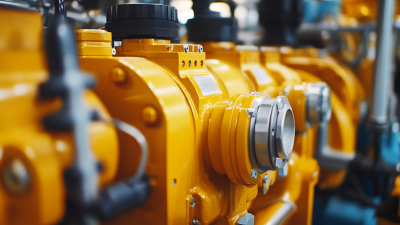

Hydraulic pumps and motors are renowned for their versatility, making them suitable for a plethora of applications across various environments. Whether in construction, manufacturing, or agricultural settings, these devices are designed to adapt and perform efficiently. Their ability to generate considerable force from a compact size allows them to operate in tight spaces, which is often a requirement in many industrial and mobile applications. This adaptability extends to different fluid types, enabling hydraulic systems to function effectively in diverse conditions, from extreme heat to cold and even in underwater environments.

Hydraulic pumps and motors are renowned for their versatility, making them suitable for a plethora of applications across various environments. Whether in construction, manufacturing, or agricultural settings, these devices are designed to adapt and perform efficiently. Their ability to generate considerable force from a compact size allows them to operate in tight spaces, which is often a requirement in many industrial and mobile applications. This adaptability extends to different fluid types, enabling hydraulic systems to function effectively in diverse conditions, from extreme heat to cold and even in underwater environments.

Tips: When selecting hydraulic pumps for specific applications, consider the operational environment. Ensure that the chosen pump is compatible with environmental factors such as temperature and moisture. Additionally, regular maintenance checks can enhance the performance and longevity of hydraulic systems, preventing costly downtime.

Moreover, hydraulic pumps and motors contribute to enhanced productivity due to their high power-to-weight ratio. This advantage allows operators to achieve significant tasks quickly, which is crucial in time-sensitive projects. Implementing hydraulic solutions can also lead to energy efficiency, as they often require less energy to perform the same work compared to mechanical systems.

Tips: To maximize efficiency, monitor the system pressure regularly and adjust it according to the workload. Proper calibration can significantly enhance the system's performance and prevent hydraulic failures.

Lower Maintenance Costs Associated with Hydraulic Machinery

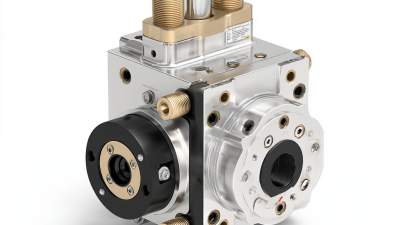

Hydraulic machinery provides numerous benefits, particularly when it comes to maintenance costs. One of the key advantages of hydraulic pumps and motors is their relatively low maintenance requirements compared to other mechanical systems. This is largely due to the design of hydraulic components, which often feature fewer moving parts than traditional mechanical systems. With less wear and tear over time, operators can expect reduced frequency and costs associated with repairs or replacements.

Moreover, hydraulic systems are generally more resilient to harsh working conditions, which can lead to longer operational lifespans. As hydraulic fluid acts as a lubricant, it minimizes friction and heat generation during operation. This results in lesser degradation of components, allowing for greater reliability and sustainability in various industrial applications. The combination of reduced maintenance needs and enhanced durability makes hydraulic machinery an economically sound choice for businesses looking to optimize their operational efficiency and reduce overall costs.

Hydraulic pumps and motors are renowned for their versatility, making them suitable for a plethora of applications across various environments. Whether in construction, manufacturing, or agricultural settings, these devices are designed to adapt and perform efficiently. Their ability to generate considerable force from a compact size allows them to operate in tight spaces, which is often a requirement in many industrial and mobile applications. This adaptability extends to different fluid types, enabling hydraulic systems to function effectively in diverse conditions, from extreme heat to cold and even in underwater environments.

Hydraulic pumps and motors are renowned for their versatility, making them suitable for a plethora of applications across various environments. Whether in construction, manufacturing, or agricultural settings, these devices are designed to adapt and perform efficiently. Their ability to generate considerable force from a compact size allows them to operate in tight spaces, which is often a requirement in many industrial and mobile applications. This adaptability extends to different fluid types, enabling hydraulic systems to function effectively in diverse conditions, from extreme heat to cold and even in underwater environments.