Understanding Backhoe Hydraulic Pump Specifications: A Comprehensive Guide for Global Buyers

In the world of construction and excavation, the efficiency of machinery is paramount to successful project completion. Among the various components that contribute to operational performance, the Backhoe Hydraulic Pump stands out as a critical element that directly influences the functionality of backhoe loaders. Understanding the specifications and capabilities of these hydraulic pumps can be daunting, especially for global buyers who must navigate a myriad of options and varying standards. This comprehensive guide aims to demystify the complexities surrounding Backhoe Hydraulic Pump specifications, empowering buyers with the knowledge they need to make informed purchasing decisions.

As we delve deeper into the specifics of Backhoe Hydraulic Pumps, we will explore the essential features, performance metrics, and compatibility considerations that are crucial for ensuring optimal performance of backhoe equipment. Whether you are a seasoned industry professional or a newcomer to the construction sector, grasping the intricacies of these hydraulic systems will not only enhance your understanding of backhoe machinery but also enable you to select the most suitable hydraulic pump for your operational needs. Join us as we break down the vital aspects of Backhoe Hydraulic Pump specifications, paving the way for more efficient and productive construction practices.

Key Factors Influencing Backhoe Hydraulic Pump Performance and Specifications

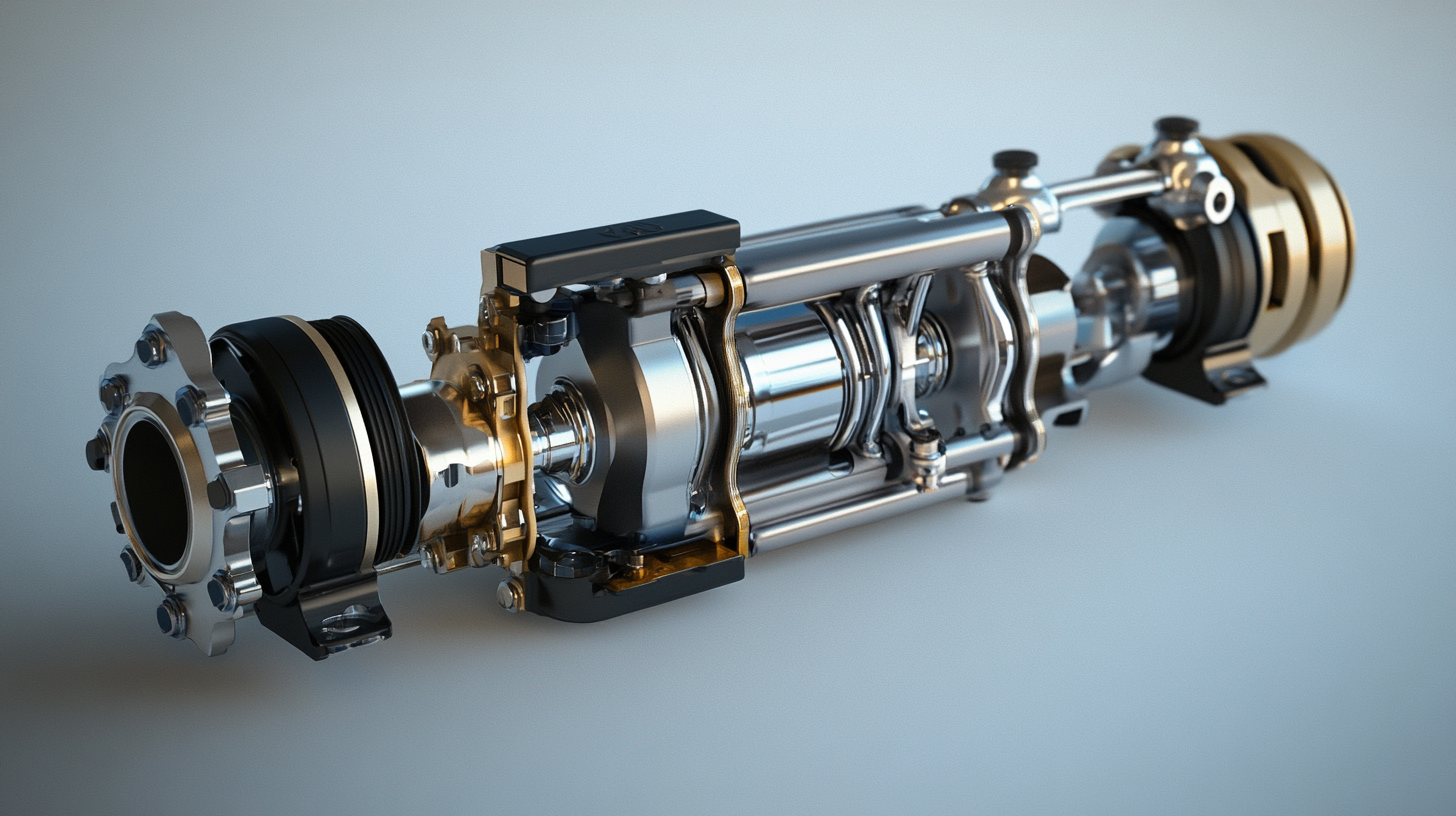

When selecting a backhoe hydraulic pump, understanding the key factors that influence its performance and specifications is crucial for global buyers. One of the primary considerations is the pump displacement, which directly affects the flow rate and power output. A higher displacement typically translates to increased hydraulic flow, enabling the backhoe to perform more demanding tasks efficiently. Buyers must assess the application requirements, as choosing a pump with the right displacement ensures optimal performance without overworking the machinery.

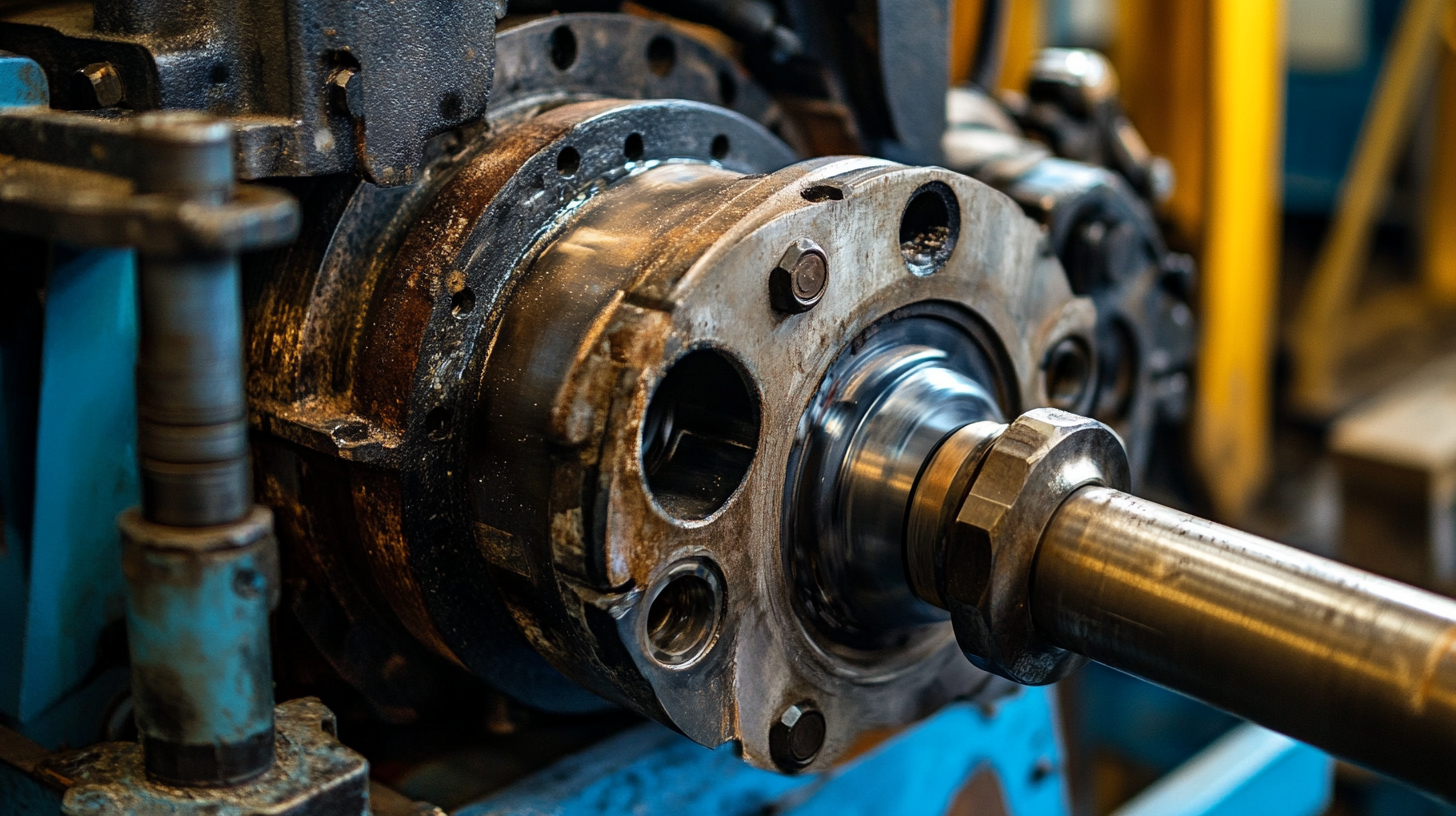

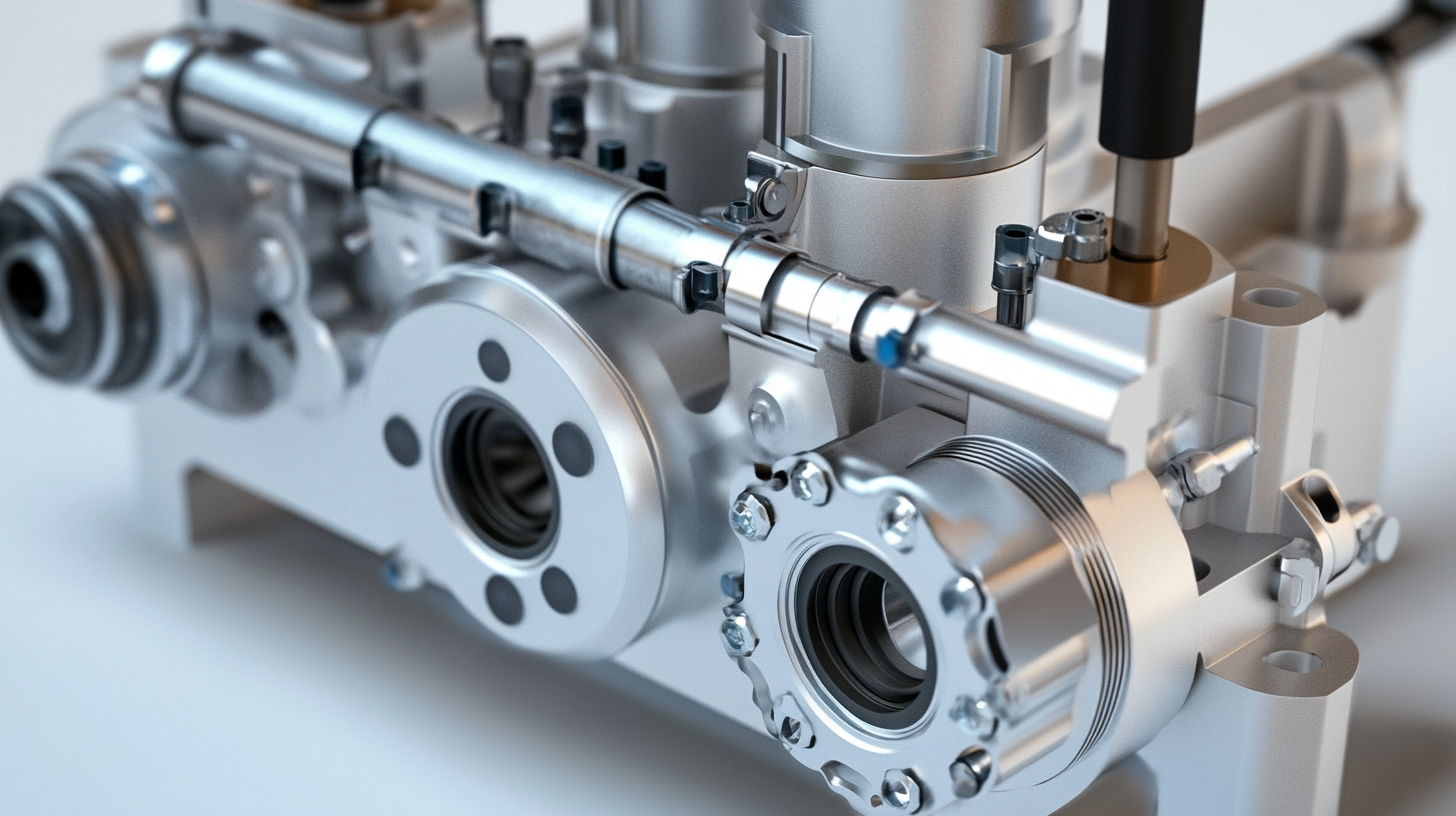

Another significant factor is the pump type, which can be classified into gear, vane, and piston pumps. Each type has its unique advantages and limitations. For instance, gear pumps are known for their simplicity and reliability in low-pressure applications, while piston pumps offer high efficiency and adaptability for variable loads at high pressures. Buyers should evaluate the specific operational needs of their backhoe to select the appropriate pump type that aligns with their performance expectations.

Additionally, the material used in the construction of hydraulic pumps plays a vital role in durability and reliability. A pump made of high-quality materials like cast iron or aluminum alloys can withstand harsh operating conditions and prolong service life. This choice becomes even more critical in environments where exposure to elements or abrasive materials is common. Understanding these specifications will empower buyers to make informed decisions that enhance the operational capabilities and longevity of their backhoe equipment.

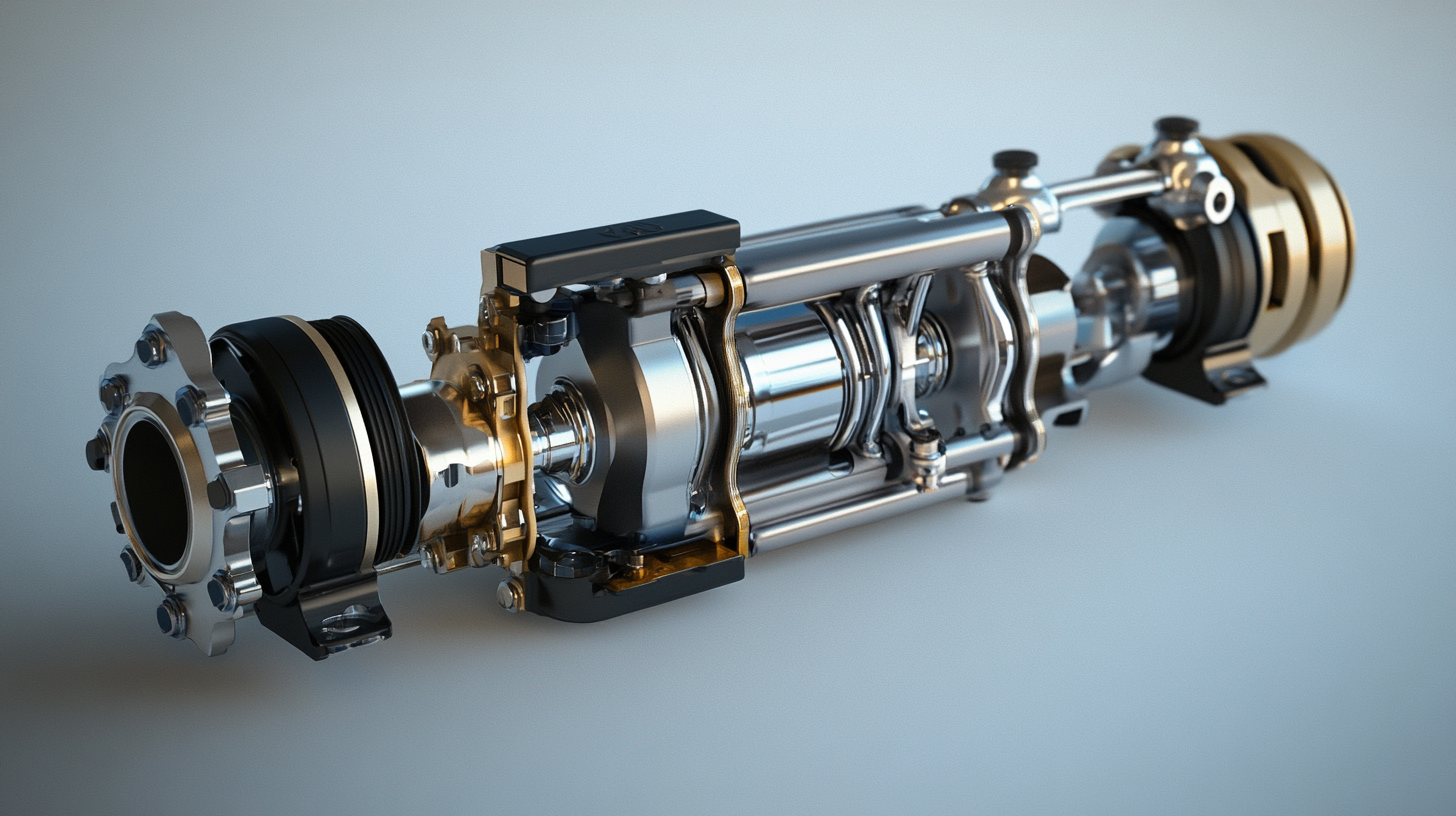

Comparative Analysis of Hydraulic Pump Types Used in Backhoes

When considering hydraulic pumps for backhoes, understanding the different types available is vital for making informed purchasing decisions. There are primarily three types of hydraulic pumps utilized in backhoes: gear pumps, piston pumps, and vane pumps. Each type offers distinct advantages and is suitable for varying operational demands. According to a recent report by MarketsandMarkets, the global hydraulic pump market is projected to grow from USD 35.7 billion in 2020 to USD 55.1 billion by 2025, underscoring the importance of selecting the right pump type for efficiency and performance.

Gear pumps, renowned for their simplicity and reliability, are often favored in low to medium-pressure applications. They provide consistent flow but may not be ideal for high-efficiency tasks due to their fixed displacement nature. On the other hand, piston pumps excel in high-pressure environments and offer variable displacement capabilities, making them more efficient for rigorous operations. A study from Research and Markets highlighted that piston pumps are expected to dominate the hydraulic pump segment, with an anticipated market share of about 60% by 2025, primarily due to their adaptability in various backhoe models.

Vane pumps represent a middle ground, combining the benefits of both gear and piston pumps. They are known for their quiet operation and smooth flow, which can contribute to reduced wear and tear on backhoe components. According to a technical review by the International Journal of Hydraulic Engineering, vane pumps are increasingly being integrated into modern backhoe designs because they can efficiently manage both constant and variable loads, making them a versatile option for global buyers. Therefore, understanding these hydraulic pump types and their operational efficiencies is crucial for maximizing the performance of backhoe equipment.

Understanding Flow Rate and Pressure Ratings in Backhoe Hydraulic Systems

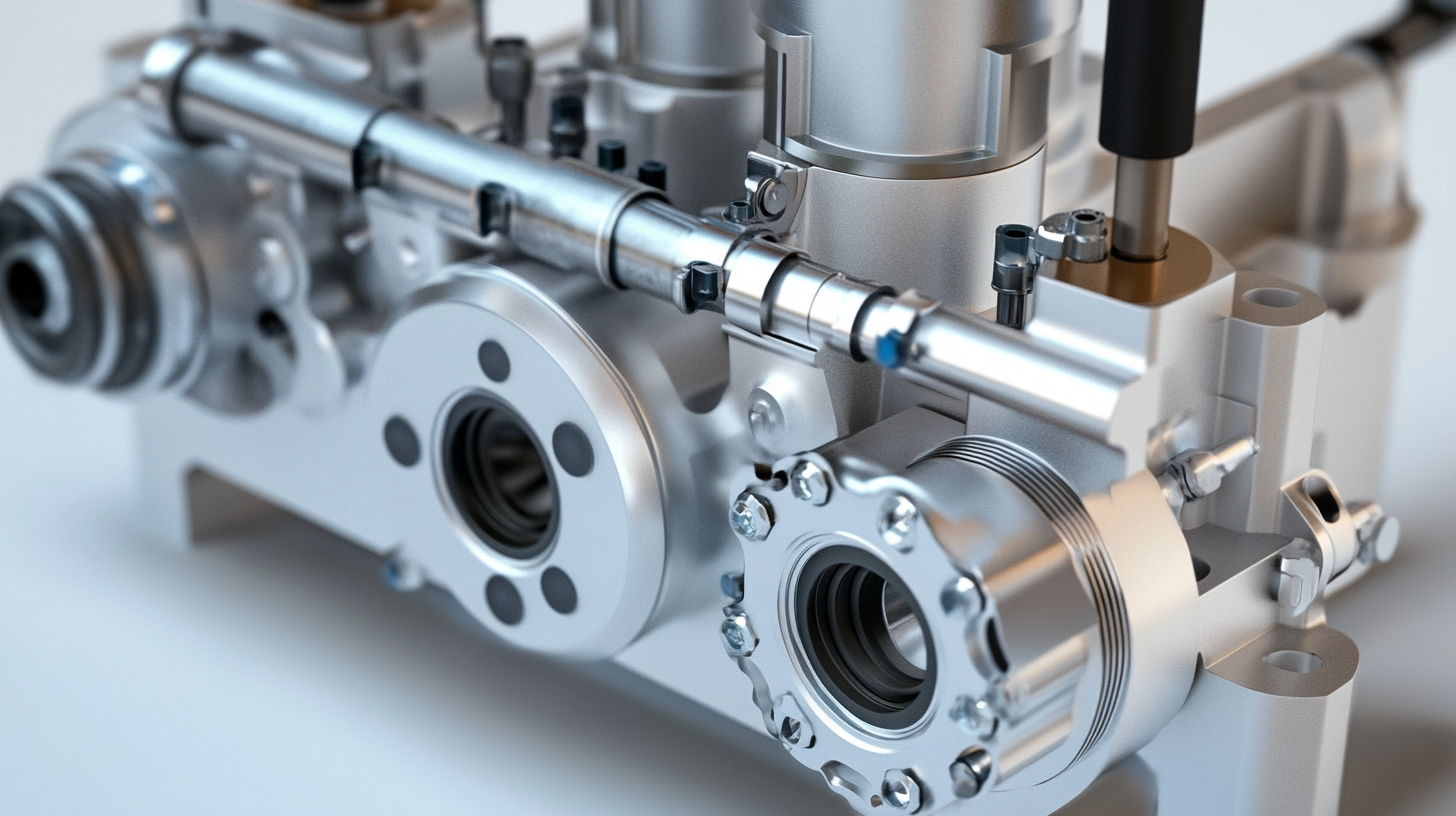

When selecting a backhoe hydraulic pump, understanding flow rate and pressure ratings is crucial for optimal performance. Flow rate, measured in gallons per minute (GPM) or liters per minute (LPM), indicates the volume of hydraulic fluid the pump can move. A higher flow rate allows the hydraulic system to operate more efficiently, powering multiple functions simultaneously without lag. For buyers, it's essential to match the pump’s flow rate to the machine's requirements to ensure that all attachments work within their designed operational capacity.

Pressure ratings, typically expressed in pounds per square inch (PSI) or bar, are equally important. They indicate the maximum pressure that the hydraulic system can handle. A pump with a higher pressure rating enables greater lifting and digging capabilities, allowing backhoes to tackle tougher jobs. However, exceeding the system’s pressure limits can lead to equipment failure or safety hazards. Buyers should evaluate the tasks the backhoe will perform and select a pump that balances flow rate and pressure ratings to meet those demands reliably.

In the global marketplace, the variety of hydraulic pumps available may lead to confusion. It's vital to consider not just the specifications, but also the compatibility of the pump with your backhoe and other hydraulic components. By understanding the nuances of flow rate and pressure ratings, buyers can make more informed decisions, ensuring that their backhoe operates efficiently and effectively in a wide range of applications.

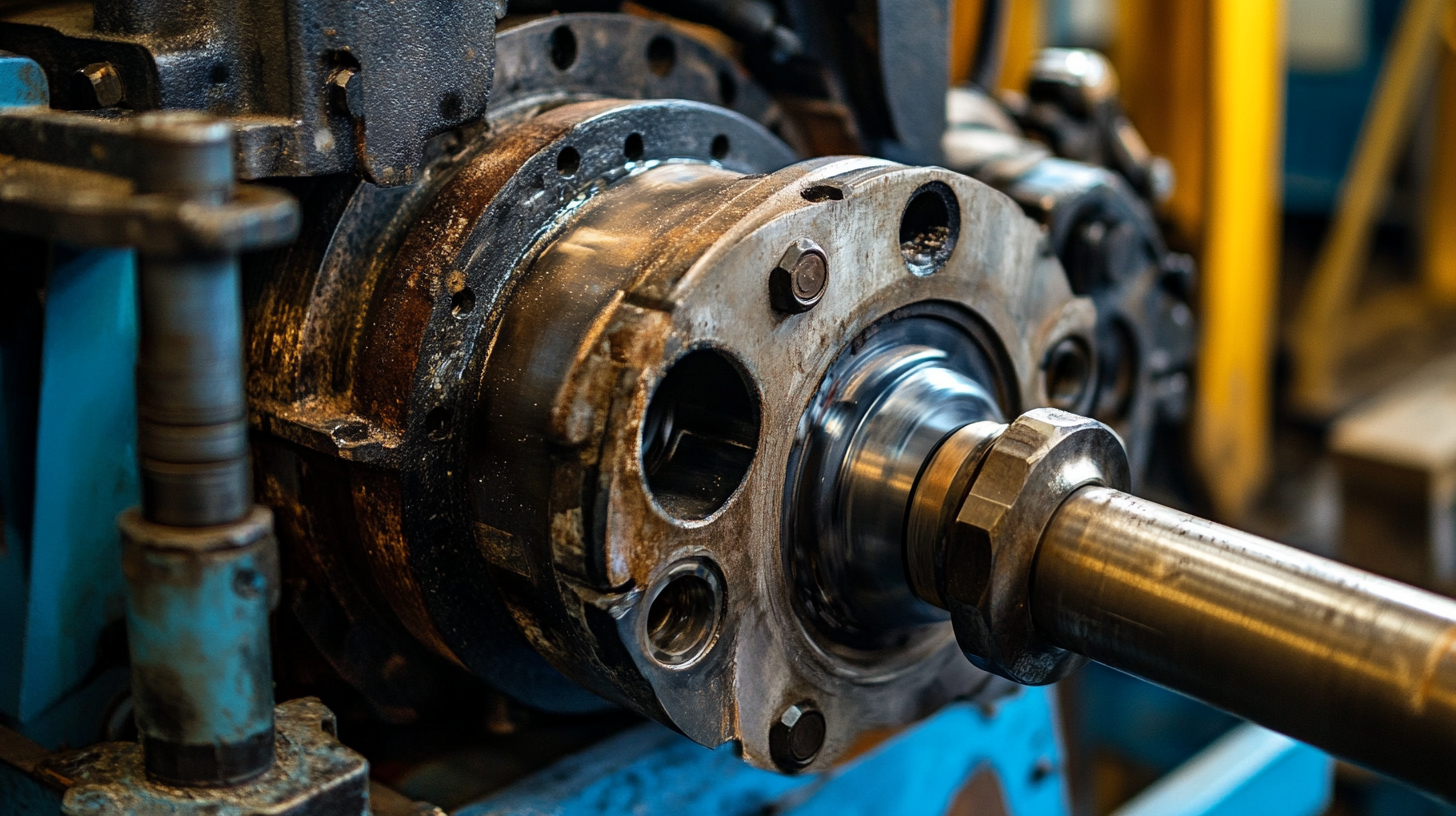

Essential Maintenance Practices for Optimizing Hydraulic Pump Longevity

Hydraulic pumps are integral to the efficiency and reliability of various machinery, including backhoes. For global buyers looking to enhance the performance and longevity of their hydraulic pumps, adhering to essential maintenance practices is paramount. One key aspect is ensuring the correct hydraulic fluid replacement, as outdated or contaminated fluid can lead to reduced pump efficiency and even failure. Proper maintenance management has been shown to improve the lifespan of hydraulic systems significantly, with studies indicating that regular fluid changes can boost pump longevity by up to 30%.

As we approach 2025, innovations in pump technology are setting the stage for enhanced operational efficiency and reliability. The hydraulic gear pump market, projected to reach $12.6 billion by 2032, underscores the demand for advanced hydraulic solutions. Buyers should focus on selecting pumps that incorporate the latest technologies, such as smart sensors that monitor oil quality and system performance in real-time. This proactive approach not only prevents mechanical failures but also optimizes maintenance schedules based on actual operating conditions, thereby reducing downtime and operational costs.

Moreover, the importance of adhering to maintenance schedules cannot be overstated. Implementing reliability-centered maintenance (RCM) practices can lead to significant improvements in efficiency and safety. By focusing on critical components and their maintenance needs, companies can significantly enhance the reliability of hydraulic systems. As industries increasingly prioritize sustainable practices, the future of hydraulic pump technology looks promising, with innovations aiming to reduce waste and improve overall system sustainability while maintaining peak performance.

Global Standards and Certifications for Backhoe Hydraulic Pumps Explained

When purchasing backhoe hydraulic pumps, understanding global standards and certifications is crucial for ensuring quality and reliability. Various international organizations, such as the International Organization for Standardization (ISO) and the American National Standards Institute (ANSI), establish benchmarks that manufacturers must meet to compete in the global market. These standards cover a wide range of specifications, including performance, safety, and environmental considerations, ensuring that buyers receive products that adhere to strict quality controls.

One significant certification relevant to hydraulic pumps is the ISO 9001, which focuses on quality management systems. This certification assures buyers that the manufacturer follows established processes that enhance productivity and minimize errors. In addition, the ISO 14001 certification emphasizes environmental management, signifying that the production methods of the hydraulic pumps are eco-friendly and sustainable. Buyers should look for these certifications when evaluating suppliers, as they indicate a commitment to quality and environmental responsibility.

Furthermore, region-specific certifications can play a vital role in the selection process. For instance, CE marking in Europe indicates compliance with safety standards, while the UL mark in North America ensures compliance with electrical safety. Familiarizing oneself with these requirements not only aids in making informed purchasing decisions but also enhances compliance with local regulations, ultimately leading to better performance and longevity of the backhoe's hydraulic system. By prioritizing suppliers with these certifications, global buyers can secure superior hydraulic pumps that will meet their operational needs.