7 Best Hydraulic Pump Motors for Ultimate Performance in 2023

In 2023, the demand for Hydraulic Pump Motors continues to surge, driven by the expanding applications across various industries such as construction, agriculture, and manufacturing. According to a recent market analysis by Fortune Business Insights, the global hydraulic pump market is projected to reach $16.3 billion by 2028, growing at a CAGR of 5.8%. This highlights the critical role that hydraulic systems play in enhancing productivity and efficiency. As businesses seek to optimize their operations, selecting the right hydraulic pump motor has become essential for achieving ultimate performance. This article explores the seven best hydraulic pump motors on the market, providing insights into their design, efficiency, and application suitability, ensuring that professionals can make informed decisions to meet their specific operational needs.

Choosing the Right Hydraulic Pump Motor for Your Application

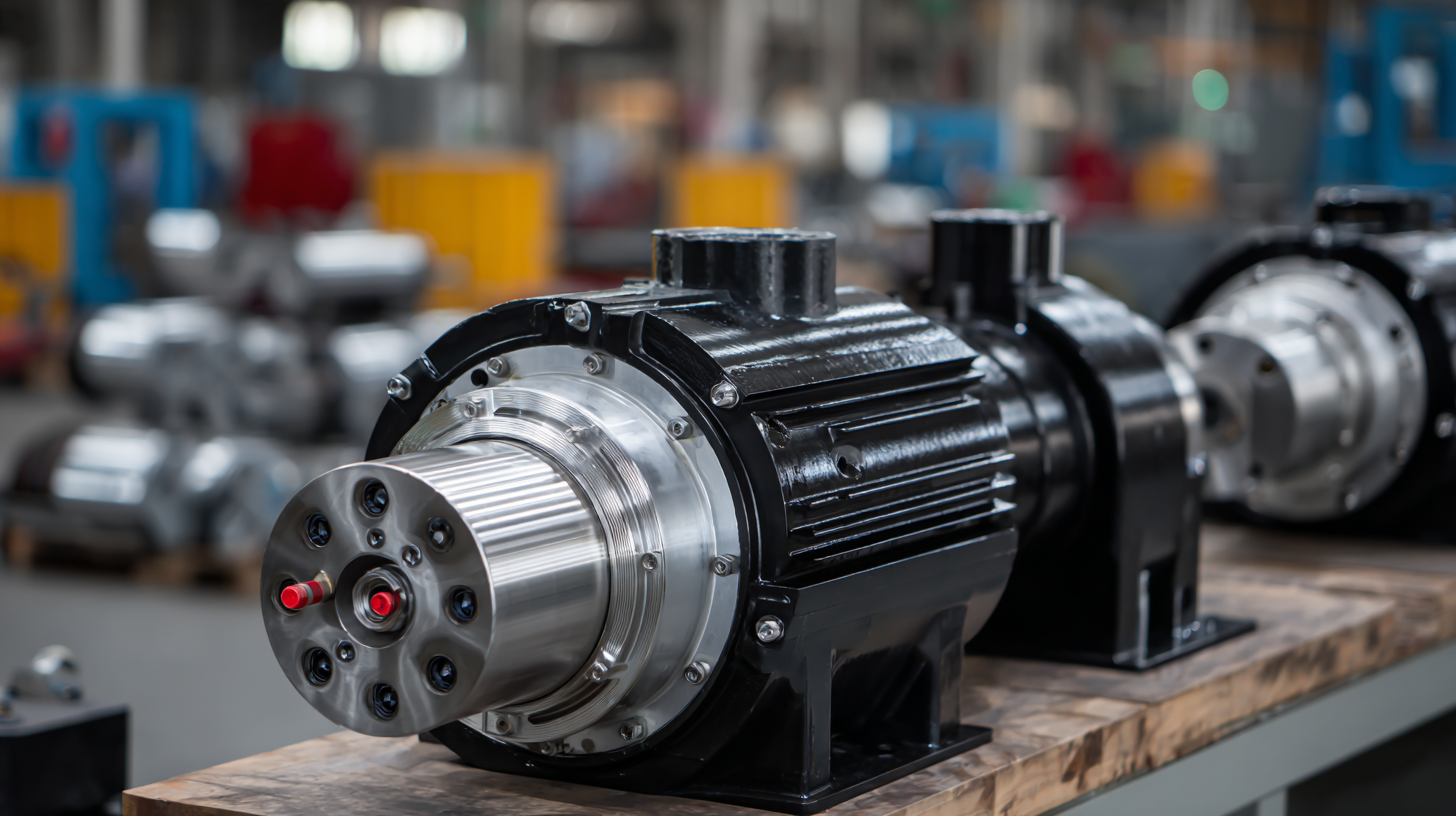

When it comes to selecting the right hydraulic pump motor for your application, it’s essential to consider several key factors that will directly impact performance and efficiency. Firstly, understanding the specific requirements of your system—including flow rate, pressure, and speed—is crucial. Different applications may demand variable speed motors for precision control, or high-torque options for heavy-duty tasks. By evaluating these needs, you can narrow down your choices to find a motor that aligns perfectly with your operational goals.

Another critical aspect to consider is the environment in which the hydraulic pump motor will operate. Factors such as temperature fluctuations, exposure to chemicals, and space constraints are vital in determining the suitable type of motor. For instance, if your application is in a harsh environment, you may want to opt for motors with protective enclosures or those designed specifically for outdoor use. Additionally, energy efficiency is a growing concern, and selecting a motor that meets or exceeds standards can lead to significant cost savings over time. By taking these considerations into account, you can optimize your hydraulic system’s performance with the ideal pump motor tailored to your specific needs.

Top Features to Look for in High-Performance Hydraulic Pump Motors

When choosing hydraulic pump motors for ultimate performance, several key features should be prioritized to ensure efficiency and reliability. One of the most critical aspects is the motor’s power-to-weight ratio. According to a report by MarketsandMarkets, industries are increasingly demanding motors that deliver higher power outputs while minimizing weight, which directly impacts equipment portability and ease of installation. High-performance hydraulic pump motors often utilize advanced materials and design techniques that enhance this ratio, allowing for superior energy conversion and operational efficiency.

Another essential feature to consider is the motor's efficiency rating. A study from the National Renewable Energy Laboratory highlights that hydraulic systems can account for up to 30% of energy losses in industrial applications. Selecting a motor with an efficiency rating above 90% can significantly reduce operational costs and environmental impact. Additionally, features like variable speed control and robust thermal management systems are crucial for maintaining optimal performance under varying loads. By focusing on these top features, industries can ensure they invest in hydraulic pump motors that not only meet their operational needs but also enhance overall productivity.

7 Best Hydraulic Pump Motors for Ultimate Performance in 2023

Comparing Electric vs. Diesel Hydraulic Pump Motors: Which is Best?

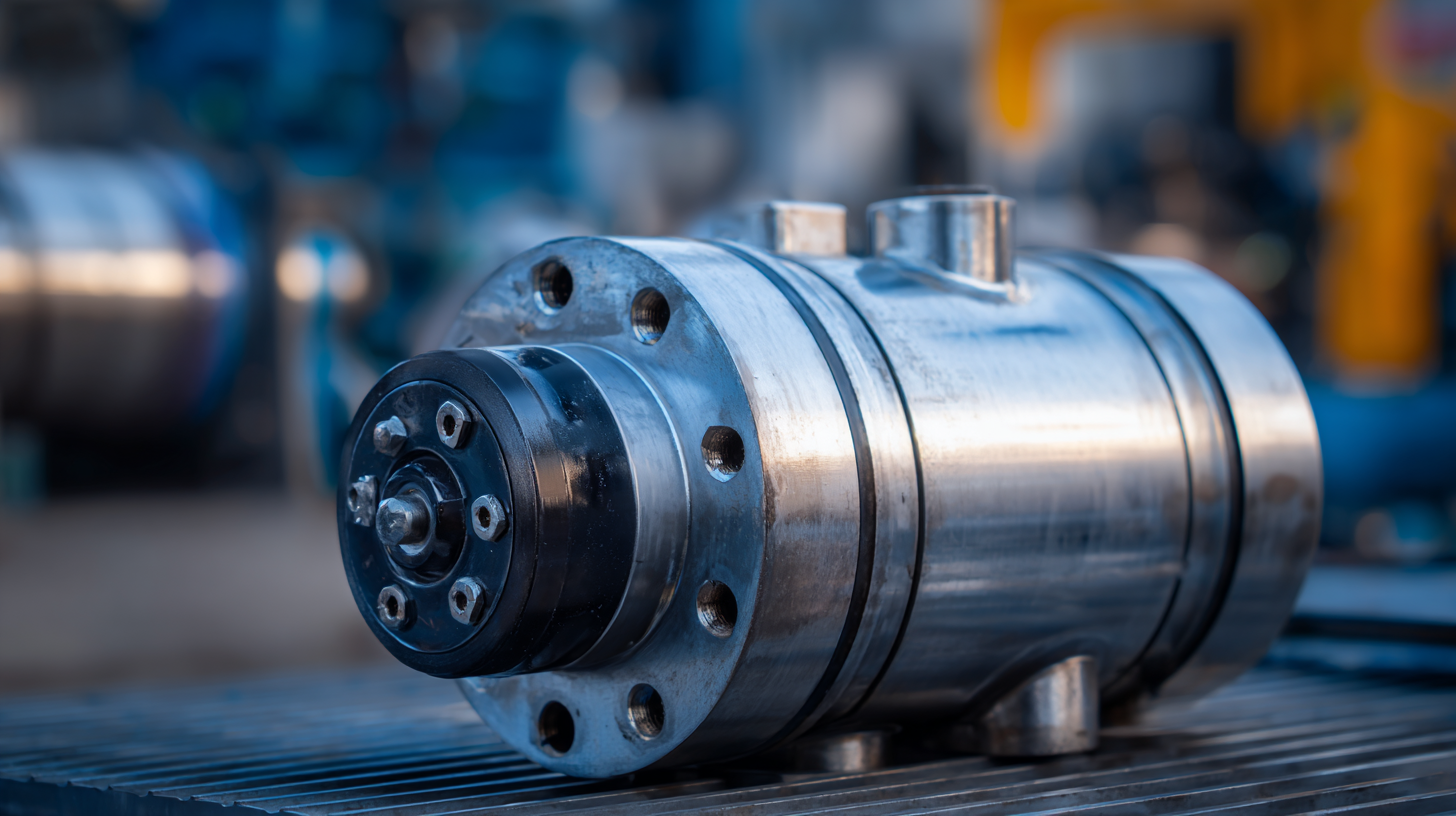

When it comes to selecting a hydraulic pump motor, the debate between electric and diesel options remains a hot topic among professionals. Electric hydraulic pump motors are known for their efficiency and lower operating costs. They offer smooth and quiet operation, making them ideal for indoor applications where noise levels must be minimized. Additionally, electric motors have fewer moving parts, which often leads to less maintenance and longer operational lifespans. This makes them a popular choice for tasks requiring precision and consistency, such as in manufacturing and robotics.

On the other hand, diesel hydraulic pump motors bring a different set of advantages, especially in outdoor or remote environments where electricity may not be readily available. Diesel motors are typically more powerful, providing higher torque and better performance for heavy-duty applications like construction and agriculture. They are rugged and can withstand harsh conditions, making them reliable for demanding environments. However, users must consider factors such as fuel availability and emissions regulations when opting for diesel motors. Ultimately, the choice between electric and diesel hydraulic pump motors will depend on application requirements, efficiency needs, and operational environments.

Maintenance Tips to Extend the Life of Your Hydraulic Pump Motor

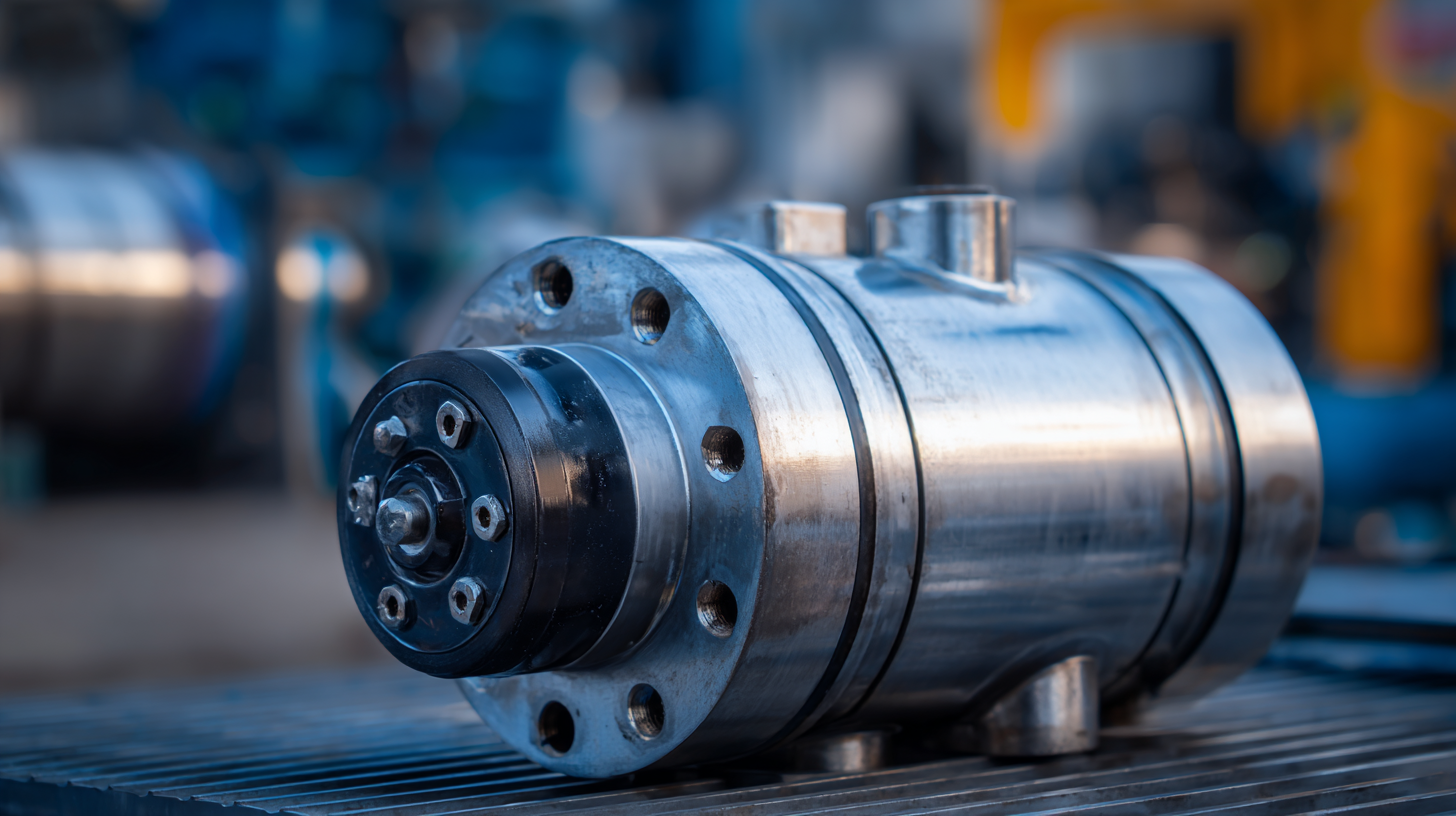

Maintaining your hydraulic pump motor is crucial for ensuring longevity and optimal performance. In a landscape where energy efficiency is becoming increasingly important, manufacturers are innovating to enhance motor performance while minimizing power consumption. Regular maintenance practices not only help in identifying potential issues early but also improve the overall efficiency of your pumping systems, contributing to more sustainable operations.

Tip 1: Schedule Routine Inspections – Establish a routine maintenance schedule that includes inspections of hydraulic pumps and motors. Regular checks can help detect wear and tear before they become major issues. According to recent industry reports, nearly 70% of hydraulic system failures can be traced back to inadequate maintenance practices.

Tip 2: Simplify Disassembly and Reassembly – Take advantage of the new resources available from suppliers that offer detailed step-by-step disassembly and reassembly guides in video and PDF formats. This can dramatically reduce downtime during maintenance activities, as workers will spend less time figuring out how to access and service the components.

Staying proactive about maintenance not only extends the life of your hydraulic pump motor but also maximizes efficiency across your operations, allowing for greater profitability and reduced environmental impact.

The Future of Hydraulic Technology: Trends to Watch in 2023

In 2023, the hydraulic technology landscape is rapidly evolving, driven by advancements in efficiency and sustainability. Key trends are emerging that highlight the importance of electric motor systems as they gain traction over traditional hydraulic pumps. These systems not only reduce carbon footprints but also offer enhanced torque and speed control, making them ideal for various industrial applications.

To capitalize on these trends, consider integrating smart hydraulic systems equipped with IoT capabilities. These systems allow for real-time monitoring and diagnostics, which can significantly improve operational efficiency and reduce downtime. Remember to choose hydraulic pump motors that support predictive maintenance features to optimize performance and longevity.

Moreover, as the demand for automation increases, selecting hydraulic solutions that are compatible with automation technologies is essential. This integration paves the way for more synchronized operations, enhancing productivity. Always ensure that your team is updated with training in these new technologies, as embracing change is crucial for remaining competitive in the hydraulic industry.

7 Best Hydraulic Pump Motors for Ultimate Performance in 2023 - The Future of Hydraulic Technology: Trends to Watch in 2023

| Motor Type |

Power Output (HP) |

Max Pressure (PSI) |

Efficiency (%) |

Weight (lbs) |

Price (USD) |

| Gear Motor |

15 |

3000 |

85 |

50 |

750 |

| Piston Motor |

20 |

3500 |

90 |

65 |

900 |

| Vane Motor |

10 |

2000 |

80 |

40 |

500 |

| Combined Gear + Piston |

25 |

4000 |

88 |

70 |

1200 |

| Electric Motor |

30 |

4500 |

92 |

80 |

1500 |

| Solar Hydraulic Motor |

5 |

1500 |

75 |

35 |

400 |

| Battery-Powered Motor |

8 |

2500 |

79 |

45 |

650 |