How to Choose the Right Hydraulic Pump from Our Comprehensive Catalog

In the ever-evolving landscape of industrial machinery, selecting the right hydraulic pump is crucial for optimizing performance and efficiency. According to a recent industry report by MarketsandMarkets, the global hydraulic pump market is projected to reach USD 11.87 billion by 2025, growing at a CAGR of 6.4% from 2020. With numerous options available, navigating through a Hydraulic Pump Catalog can seem daunting. Factors such as application requirements, system compatibility, and maintenance needs all play a vital role in making an informed decision. This blog aims to demystify the process of choosing the right hydraulic pump by providing insights into key considerations and helping professionals leverage available resources for optimal performance in their operations.

Understanding the Different Types of Hydraulic Pumps Available in Our Catalog

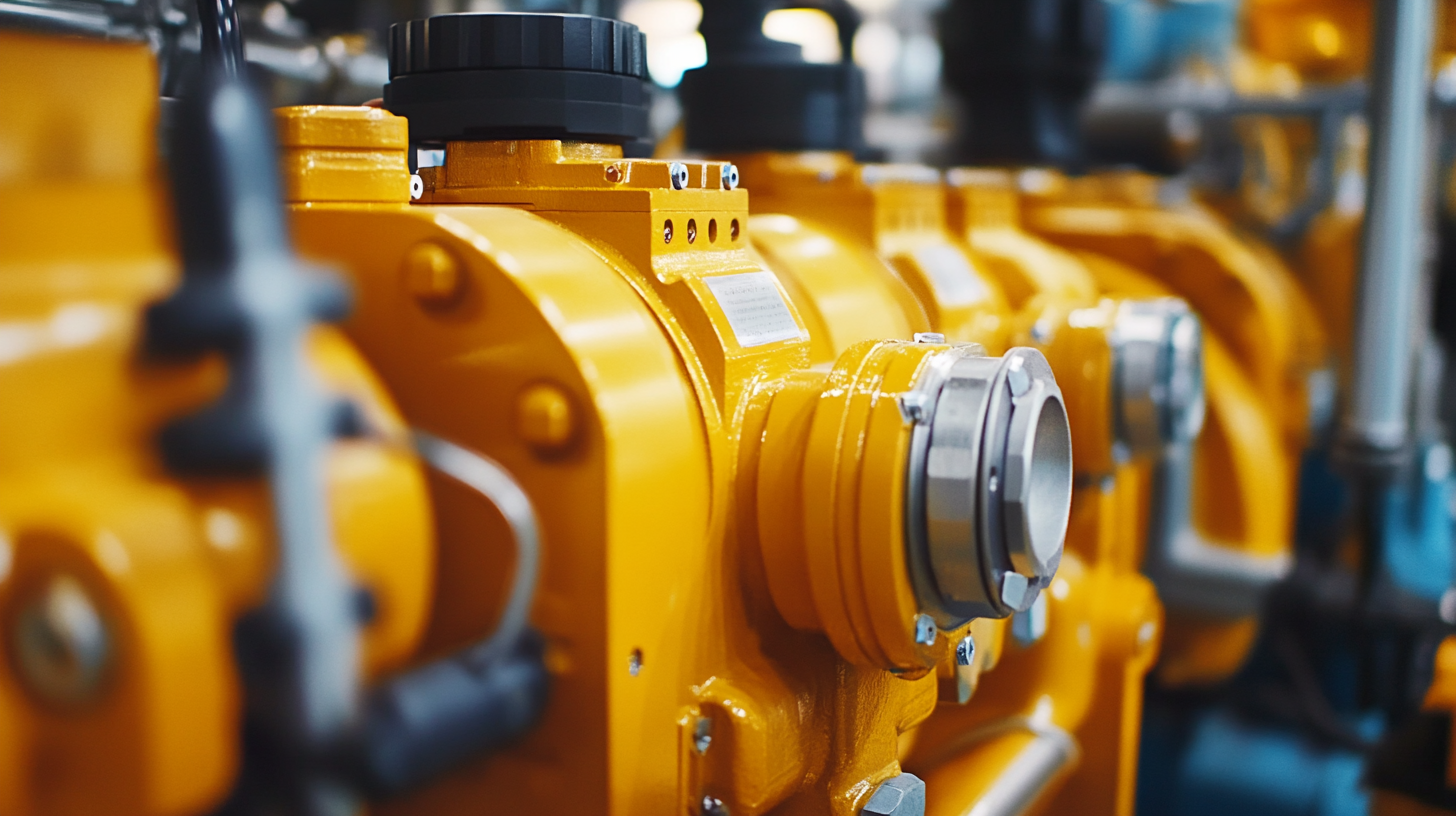

When selecting the right hydraulic pump for your needs, it's crucial to understand the various types available in our catalog. Hydraulic pumps can be categorized into two main types: gear pumps and piston pumps. Gear pumps are often favored for their simplicity and reliability, making them ideal for low-pressure applications. They utilize interlocking gears to move fluid, ensuring a steady flow rate, which is perfect for many industrial uses.

On the other hand, piston pumps are designed for high-pressure applications and provide superior efficiency. These pumps use a series of pistons to create pressure and are ideal for more demanding systems such as hydraulic machinery and heavy equipment. In our comprehensive catalog, you will find a range of options, including fixed displacement and variable displacement pumps, each tailored to meet specific operational requirements. By understanding these distinctions, you can make an informed decision that aligns perfectly with your project demands.

How to Choose the Right Hydraulic Pump from Our Comprehensive Catalog

| Pump Type |

Description |

Typical Applications |

Flow Rate (L/min) |

Pressure (Bar) |

| Gear Pump |

A rotary pump that uses gears to pump fluid. |

Construction, Agriculture |

10-100 |

50-200 |

| Piston Pump |

Uses pistons to create pressure and move fluid. |

Oil & Gas, Hydraulic Systems |

5-250 |

100-400 |

| Vane Pump |

A pump that uses spinning vanes to generate flow. |

Mobile Equipment, Industrial Machinery |

20-150 |

40-250 |

| Diaphragm Pump |

Uses a diaphragm to create a suction effect. |

Chemical Processing, Food & Beverage |

1-75 |

30-100 |

Key Factors to Consider When Selecting a Hydraulic Pump for Your Application

When selecting the right hydraulic pump for your application, it's essential to consider various key factors that ensure optimal performance and efficiency. The hydraulic pump market is projected to reach $14.2 billion by 2032, with a compound annual growth rate (CAGR) of 3.4%. This growth signifies the increasing demand and importance of hydraulic systems in various sectors, largely driven by rapid global trade. Energy efficiency and sustainability have become focal points in pump design, as manufacturers seek to create components that not only meet operational demands but also contribute to environmental goals.

Tip: Always assess the specific requirements of your application such as flow rate, pressure range, and the types of hydraulic fluids involved. This information will guide you to a pump that operates effectively within your desired parameters.

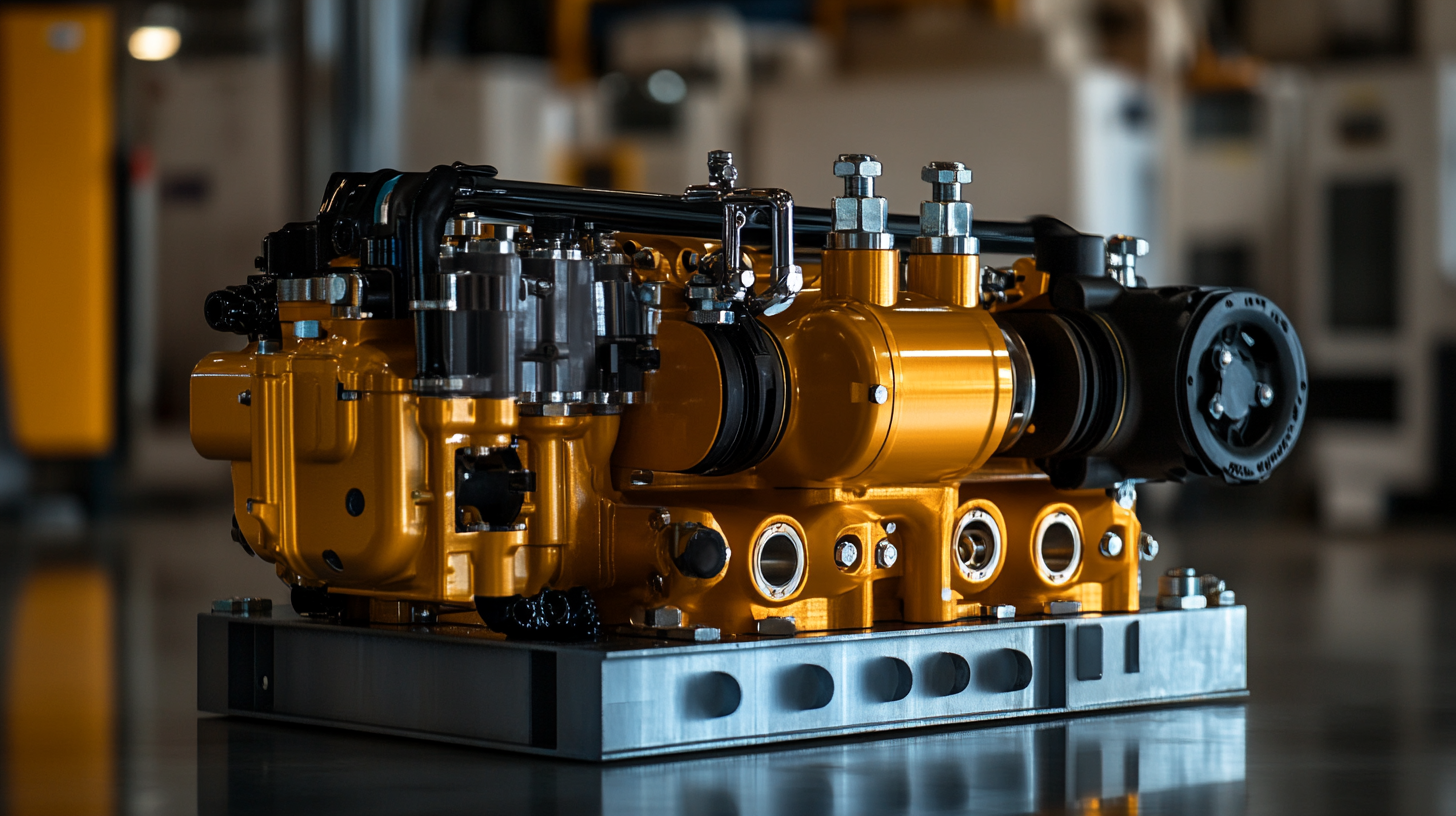

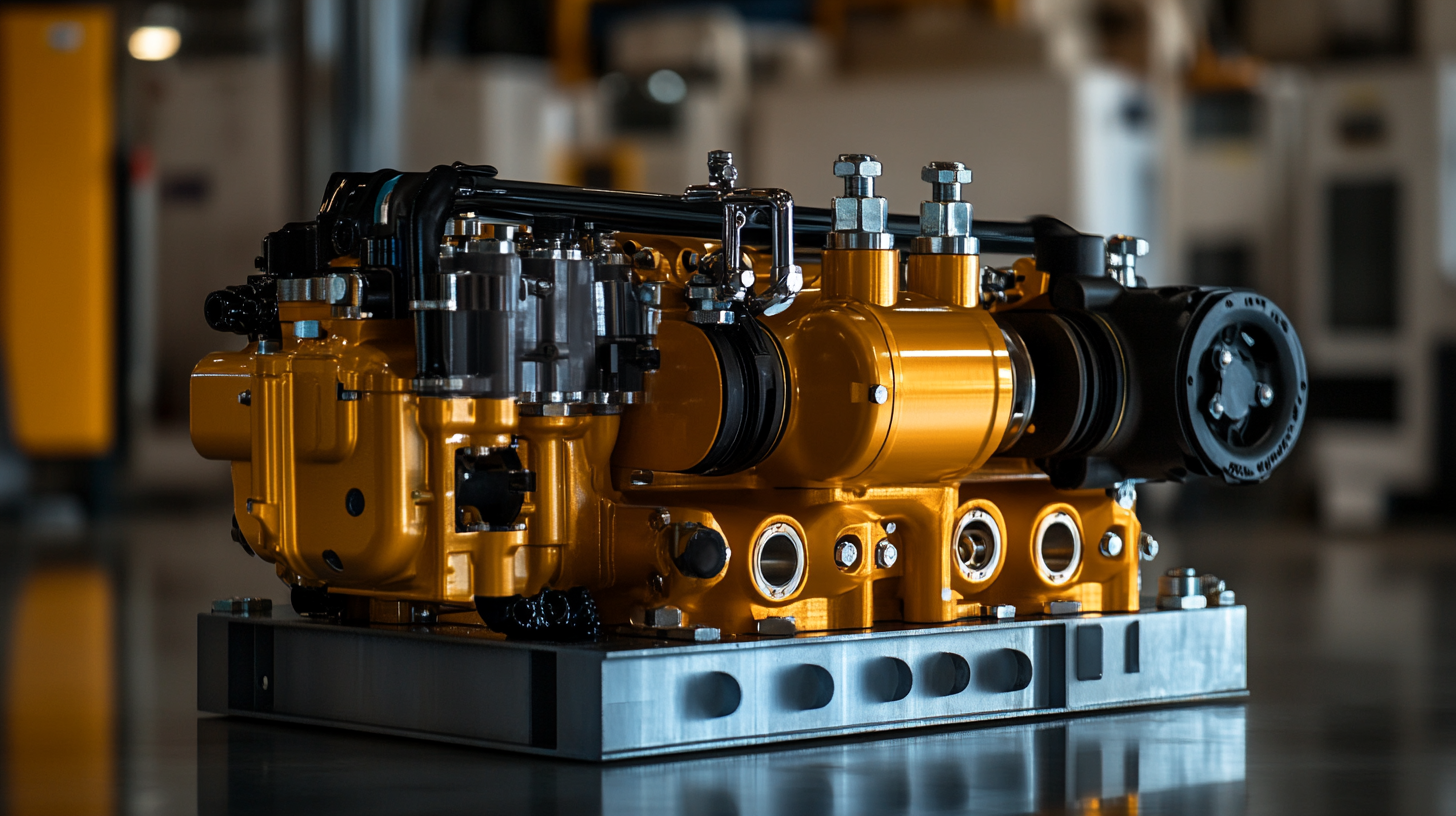

Additionally, advancements in technologies like radial piston motors and innovative gear pump designs contribute significantly to the performance of hydraulic systems. For instance, focusing on designs that enhance volumetric efficiency can reduce power losses and increase operational reliability, particularly in high-pressure environments.

Tip: Consider compatibility with existing machinery and future maintenance needs when choosing a hydraulic pump, as these factors can impact the long-term usability and efficiency of your system.

Evaluating Pump Specifications: Flow Rate, Pressure, and Motor Compatibility

When selecting the right hydraulic pump, evaluating pump specifications is paramount. The flow rate is one of the most critical factors to consider, as it determines how much fluid the pump can move within a specified time. A higher flow rate generally indicates a more efficient pump, but it is essential to match this specification with the requirements of your hydraulic system. Too high of a flow rate can lead to energy inefficiencies and may even damage components if they are not designed to handle the increased volume.

Pressure compatibility is another crucial consideration in pump selection. Each hydraulic system operates within specific pressure ranges, and exceeding these limits can result in catastrophic failures. It is vital to choose a pump that can handle the maximum pressure required by your application without compromising performance or safety. Furthermore, ensuring that the pump motor is compatible with your existing system is essential for optimal operation. This includes assessing power ratings, voltage, and motor type to ensure seamless integration and reliability. By carefully evaluating flow rates, pressure ratings, and motor compatibility, you can confidently select the hydraulic pump that best meets your needs.

Common Mistakes to Avoid When Choosing a Hydraulic Pump

When selecting a hydraulic pump, avoiding common mistakes can significantly enhance the performance and longevity of your system. One frequent error is focusing solely on the price. While budget considerations are important, opting for the cheapest option often leads to inadequate performance, increased maintenance costs, and potential system failures. It's crucial to assess the specifications, quality, and reputation of the manufacturer, rather than just looking at upfront costs.

Another common pitfall is overlooking the specific application requirements. Each hydraulic system is unique, and factors such as flow rate, pressure, and type of fluid must be considered. Failing to match the pump to these parameters can result in inefficiencies or even damage to the system. Additionally, neglecting to consult with experts or review technical documentation can lead to these miscalculations. By taking the time to carefully analyze your needs and seeking advice, you can avoid these mistakes and ensure optimal performance of your hydraulic system.

Maintenance Tips for Ensuring Longevity of Your Chosen Hydraulic Pump

When selecting the right hydraulic pump, understanding maintenance is crucial for ensuring longevity and optimal performance. Regular maintenance not only extends the lifespan of your hydraulic pump but also minimizes the risk of unexpected downtimes. One essential tip is to keep the hydraulic fluid clean and at the recommended level. Contaminated fluid can lead to wear and tear, causing significant damage over time. Schedule periodic fluid changes based on the manufacturer’s guidelines to ensure your pump operates efficiently.

Another important aspect of maintenance is to routinely inspect the pump for any signs of leaks or wear. Early detection can prevent minor issues from escalating into major repairs. Check seals, hoses, and connections regularly, and replace worn components promptly to maintain the pump’s integrity. Additionally, ensuring that the pump operates within its specified pressure and temperature range is vital. This helps in avoiding stress on the system, further enhancing the longevity of your hydraulic pump.

Hydraulic Pump Types and Their Popularity

This pie chart illustrates the popularity of different types of hydraulic pumps based on market research. Gear pumps are the most popular, followed by piston pumps, while diaphragm pumps have the least share in the market.