Exploring the Efficiency Benefits of Bi Directional Hydraulic Pumps in Industrial Applications

In recent years, the industrial sector has increasingly recognized the benefits of incorporating Bi Directional Hydraulic Pumps into their operations, leading to enhanced efficiency and reduced operational costs. According to a report by the Hydraulic Institute, the adoption of advanced hydraulic systems can result in energy savings of up to 30%, especially in applications requiring dynamic fluid movement. Bi Directional Hydraulic Pumps offer versatile functionality by allowing fluid flow in both directions, which can significantly streamline processes and minimize energy waste. As industries continue to focus on sustainable practices and operational excellence, the role of these pumps becomes even more critical. A study by MarketsandMarkets predicts that the global hydraulic pump market will grow at a CAGR of 3.8% from 2021 to 2026, driven by the rising demand for effective hydraulic solutions. This article will explore how Bi Directional Hydraulic Pumps stand at the forefront of this evolution, delivering substantial efficiency benefits in various industrial applications.

Benefits of Bi-Directional Hydraulic Pumps in Energy Efficiency for Industrial Applications

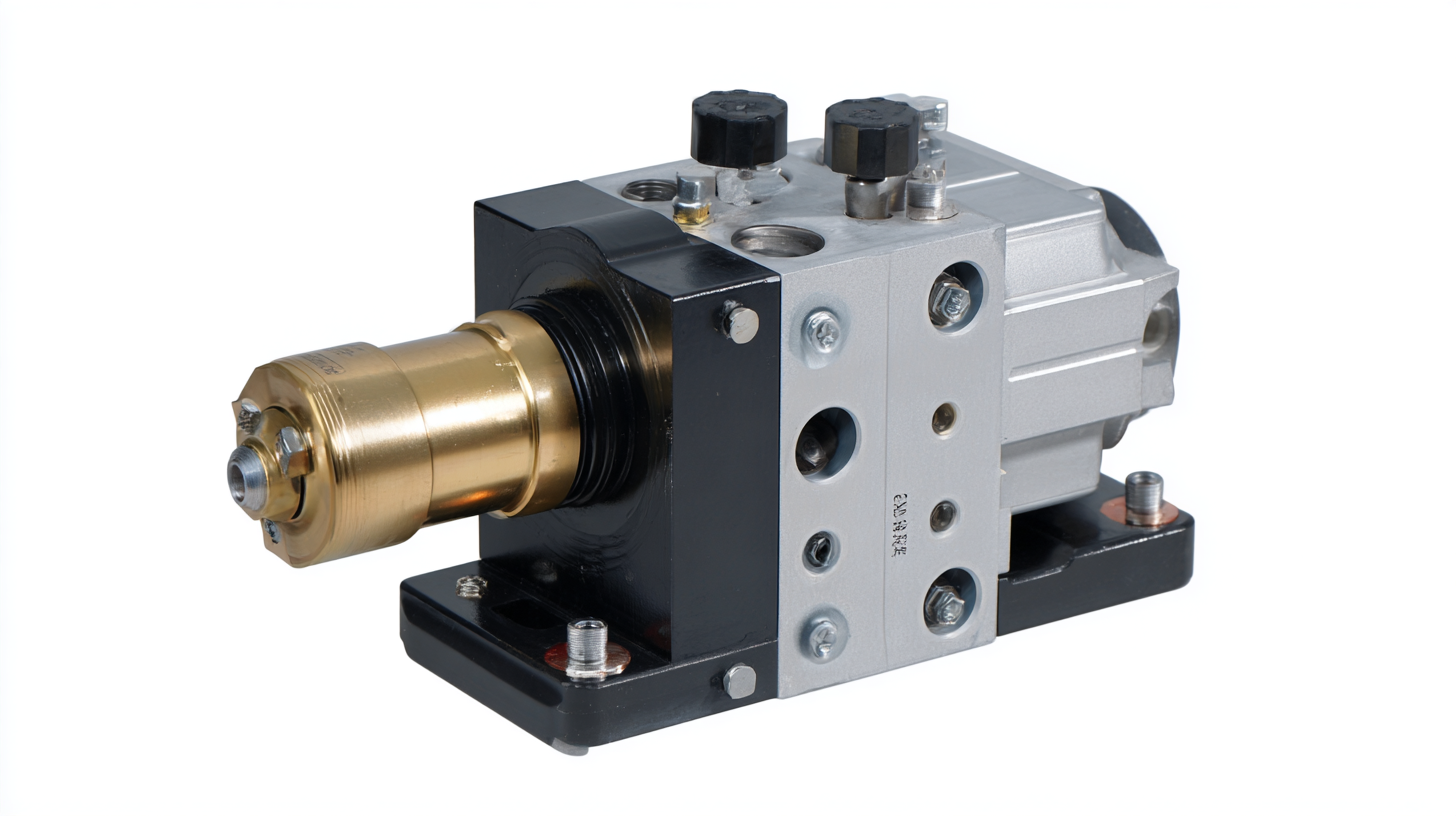

Bi-directional hydraulic pumps offer significant advantages in energy efficiency for industrial applications. These pumps can operate in both directions, enabling them to facilitate fluid movement in a more versatile and flexible manner. This dual-functionality reduces the need for additional hydraulic components, ultimately streamlining design and minimizing energy losses associated with multi-pump systems. As a result, industries can expect enhanced performance while reducing their energy consumption.

Bi-directional hydraulic pumps offer significant advantages in energy efficiency for industrial applications. These pumps can operate in both directions, enabling them to facilitate fluid movement in a more versatile and flexible manner. This dual-functionality reduces the need for additional hydraulic components, ultimately streamlining design and minimizing energy losses associated with multi-pump systems. As a result, industries can expect enhanced performance while reducing their energy consumption.

Moreover, the integration of bi-directional hydraulic pumps allows for improved system responsiveness and reduced operational costs. With their capacity to efficiently handle varying loads in both directions, these pumps can optimize hydraulic circuits, ensuring that energy is used only when necessary. This efficiency not only lowers energy bills but also contributes to a smaller carbon footprint, aligning with global sustainability initiatives. In industrial sectors where energy efficiency is paramount, bi-directional hydraulic pumps represent a breakthrough technology that delivers substantial long-term benefits.

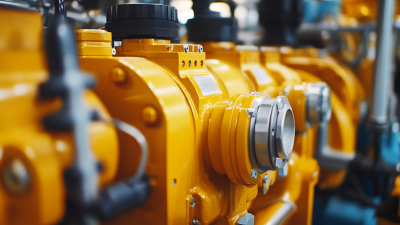

Comparative Analysis of Flow Rates: Traditional vs. Bi-Directional Pumps in Manufacturing

The efficiency of bi-directional hydraulic pumps in industrial manufacturing has garnered significant attention, particularly in the context of flow rate comparisons. These pumps allow for fluid movement in both directions, which can optimize machinery performance and energy consumption. A recent study analyzed the internal flow characteristics and entropy generation in low head bulb tubular pumps, highlighting the importance of advanced simulation methods, such as the SST k-ω turbulence model. This analysis underscores the potential of sophisticated modeling tools in revealing how bi-directional pumps can outperform traditional ones in specific manufacturing scenarios.

In the realm of flow rates, recent reports indicate that bi-directional pumps can achieve flow rate improvements of up to 20% compared to conventional pumps. These gains not only enhance operational efficiency but also reduce energy costs. The ability to control fluid flow directionally allows for more precise manufacturing processes, which is critical in industries demanding high precision. With advancements in computational fluid dynamics (CFD) providing deeper insights into flow behavior, manufacturers can leverage this knowledge to select the most efficient pumping solutions for their operations. The shift toward bi-directional technology is not just an innovation trend; it's a necessary evolution in pursuit of greater productivity and sustainability in industrial applications.

Exploring the Efficiency Benefits of Bi Directional Hydraulic Pumps in Industrial Applications - Comparative Analysis of Flow Rates: Traditional vs. Bi-Directional Pumps in Manufacturing

| Pump Type |

Flow Rate (L/min) |

Efficiency (%) |

Power Consumption (kW) |

Maintenance Frequency (Months) |

| Traditional Hydraulic Pump |

150 |

75 |

22 |

6 |

| Bi-Directional Hydraulic Pump |

180 |

85 |

20 |

12 |

| High-Performance Pump |

200 |

90 |

18 |

18 |

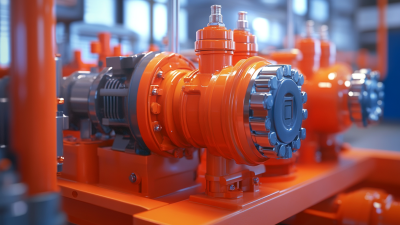

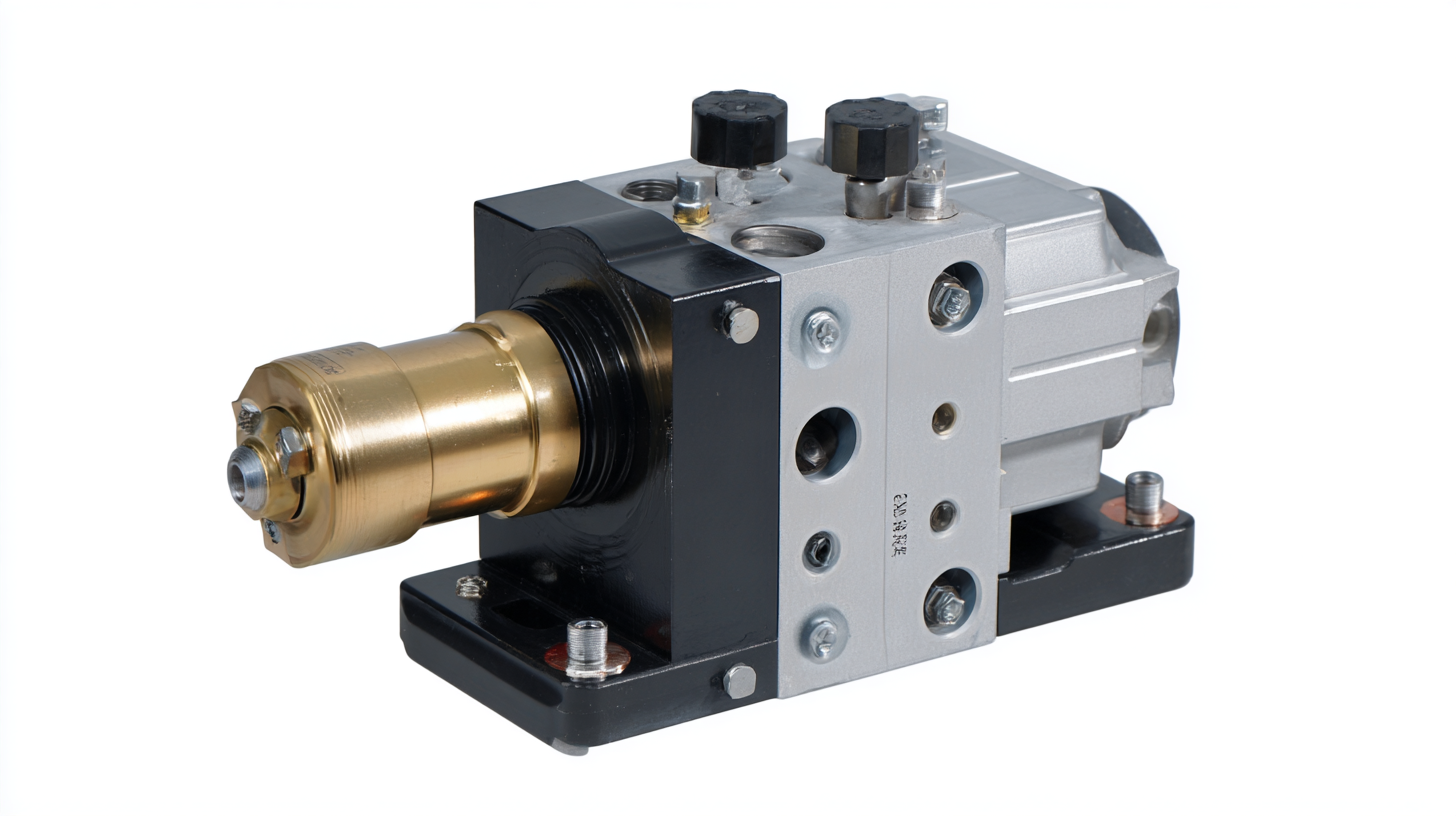

Impact of Bi-Directional Pump Technology on Operational Costs and Downtime Reduction

The integration of bi-directional hydraulic pumps in industrial applications has proven to significantly impact operational costs and downtime reduction. Recent studies indicate that by adopting such advanced pump technology, industries can enhance their efficiency by up to 30%. This is primarily due to the dual capability of these pumps to both exert and receive hydraulic fluid, leading to reduced energy consumption and lower maintenance requirements. In a recent report highlighting performance upgrades in extrusion presses, it was noted that the replacement of outdated pump systems resulted in a notable increase in speed and cooling efficiency, affirming the trend towards modernization in hydraulic systems.

Moreover, real-time data analytics and predictive maintenance tools are increasingly employed in conjunction with bi-directional pump systems to optimize operations. Companies leveraging digital twin technology have reported a 20% reduction in operational downtime by utilizing real-time monitoring to preemptively address equipment wear and potential failures. As industries further embrace automation and smart technologies, the reliance on innovative hydraulic solutions will likely continue to grow, driving operational efficiency and contributing to overall cost savings.

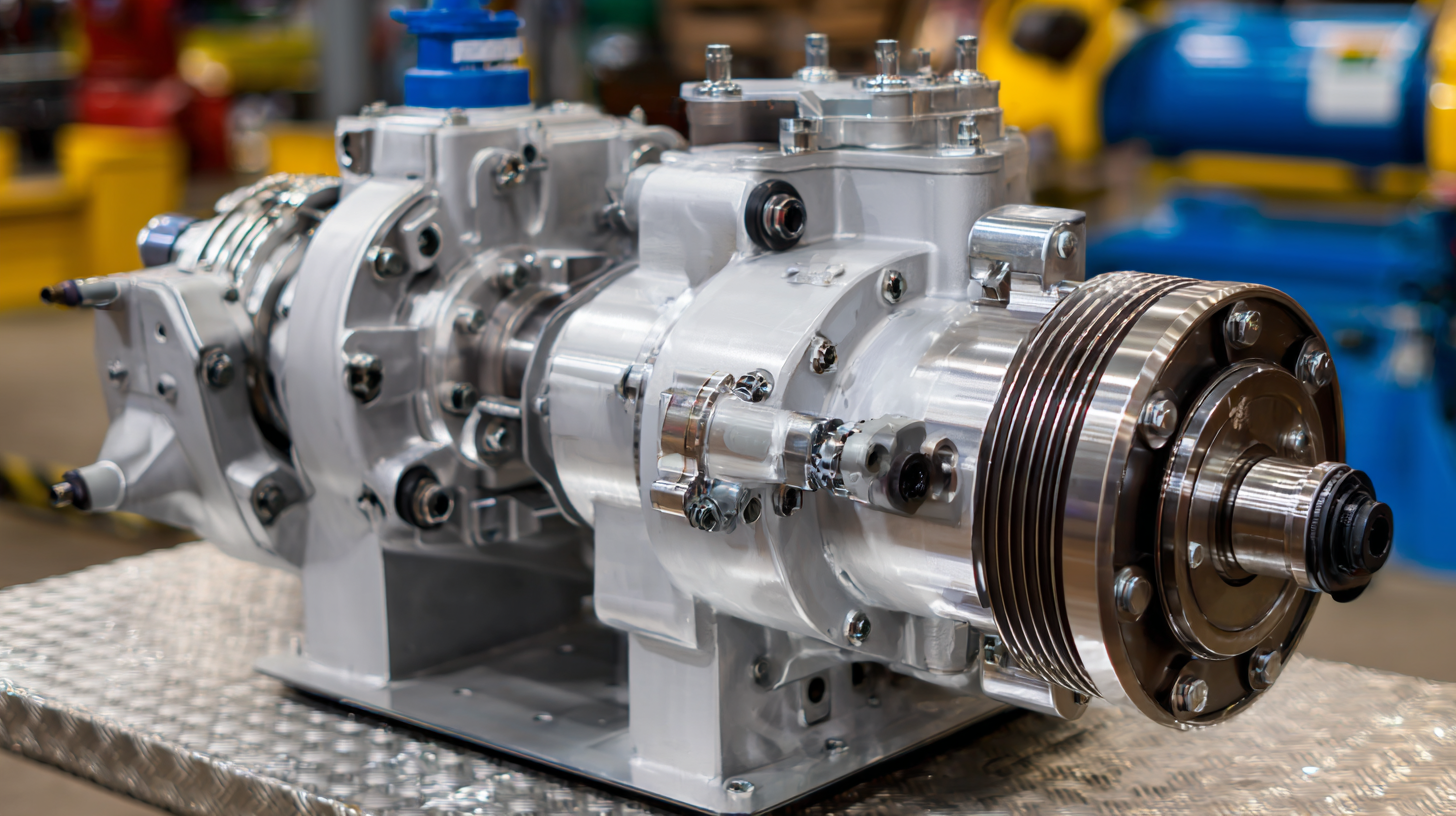

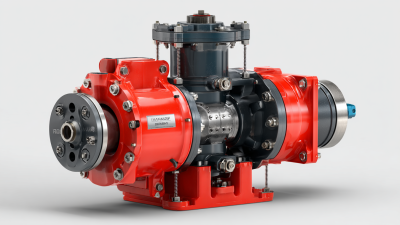

Case Studies: Successful Implementation of Bi-Directional Pumps in Various Industries

In recent years, bi-directional hydraulic pumps have gained attention in various industrial applications due to their enhanced efficiency and versatility. Case studies from multiple sectors demonstrate how these pumps are transforming operations. For instance, in the automotive industry, a manufacturer reported a 25% reduction in energy consumption after replacing traditional pumps with bi-directional systems. This shift not only streamlined assembly line processes but also significantly lowered operational costs.

Similarly, in the construction sector, a leading contractor implemented bi-directional pumps for heavy machinery, allowing for smoother transitions in hydraulic functions. This optimization led to improved machine responsiveness and increased productivity on construction sites. The ability to easily reverse the flow of hydraulic fluid proved advantageous, particularly in tasks requiring precise control and repetitive movements. As industries continue to seek innovative solutions for efficiency, the successful application of bi-directional hydraulic pumps illustrates their potential to reshape operational paradigms across the board.

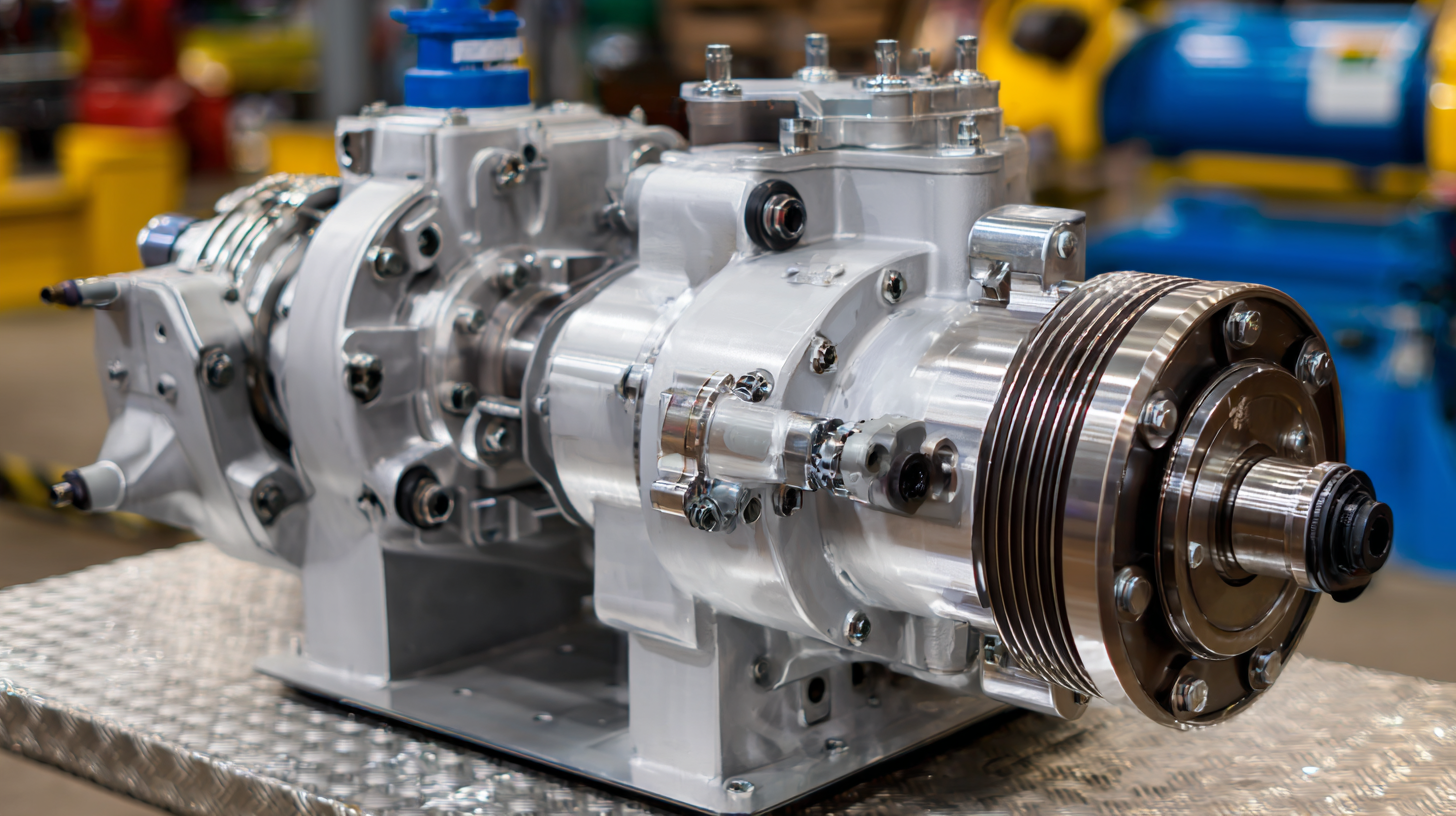

Future Trends: Innovations in Bi-Directional Hydraulic Pump Design and Efficiency Standards

The landscape of bi-directional hydraulic pump design is rapidly evolving, driven by the demand for enhanced efficiency and performance in industrial applications. Future trends indicate a strong emphasis on integrating advanced materials and smart technologies into pump design. By utilizing lightweight, high-strength materials, manufacturers can reduce energy losses and improve overall system responsiveness. Moreover, the incorporation of real-time monitoring systems can optimize performance by adjusting operational parameters dynamically, ensuring that pumps are always operating at peak efficiency.

Innovations in efficiency standards are also emerging as a significant focus in the industry. Regulatory bodies and industry leaders are increasingly advocating for stringent efficiency metrics, pushing manufacturers to innovate in energy recovery technologies and decrease environmental impact. For instance, hybrid systems that combine traditional hydraulic pumps with electric components are being developed to minimize energy consumption while maximizing output. As these trends unfold, the bi-directional hydraulic pump market is expected to experience significant growth, driven by the pursuit of sustainability and cost-effectiveness in industrial operations.

Efficiency Benefits of Bi-Directional Hydraulic Pumps

This bar chart illustrates the improvement in efficiency ratings of bi-directional hydraulic pumps over five years. The data indicates a steady increase in efficiency from 2019 to 2023, showcasing the innovations and advancements in pump design and technology within the industrial sector.