Unlocking Efficiency in Global Industries with Advanced Hydraulic Pump Solutions

In today's fast-paced industrial landscape, the demand for efficiency and reliability has never been higher. According to a report by MarketsandMarkets, the global hydraulic pump market size is projected to reach USD 15.06 billion by 2025, growing at a CAGR of 4.5% from 2020. This trend underscores the growing reliance of industries on advanced hydraulic pump solutions to optimize performance and enhance productivity. Hydraulic pumps play a critical role in various applications, from construction and agriculture to manufacturing and energy, making them essential components for driving operational excellence.

As industries around the world strive to improve efficiency and minimize downtime, innovative hydraulic pump technologies emerge as pivotal enablers of these goals. A study by ResearchAndMarkets highlights that investments in hydraulic systems are expected to surge, with a significant shift towards energy-efficient solutions that reduce operational costs. With advancements in design, materials, and control systems, modern hydraulic pumps are not only more efficient but also more sustainable, addressing the pressing need for eco-friendly practices in industrial processes. As we delve deeper into the transformative potential of advanced hydraulic pump solutions, it becomes clear that they are set to unlock new levels of efficiency across global industries.

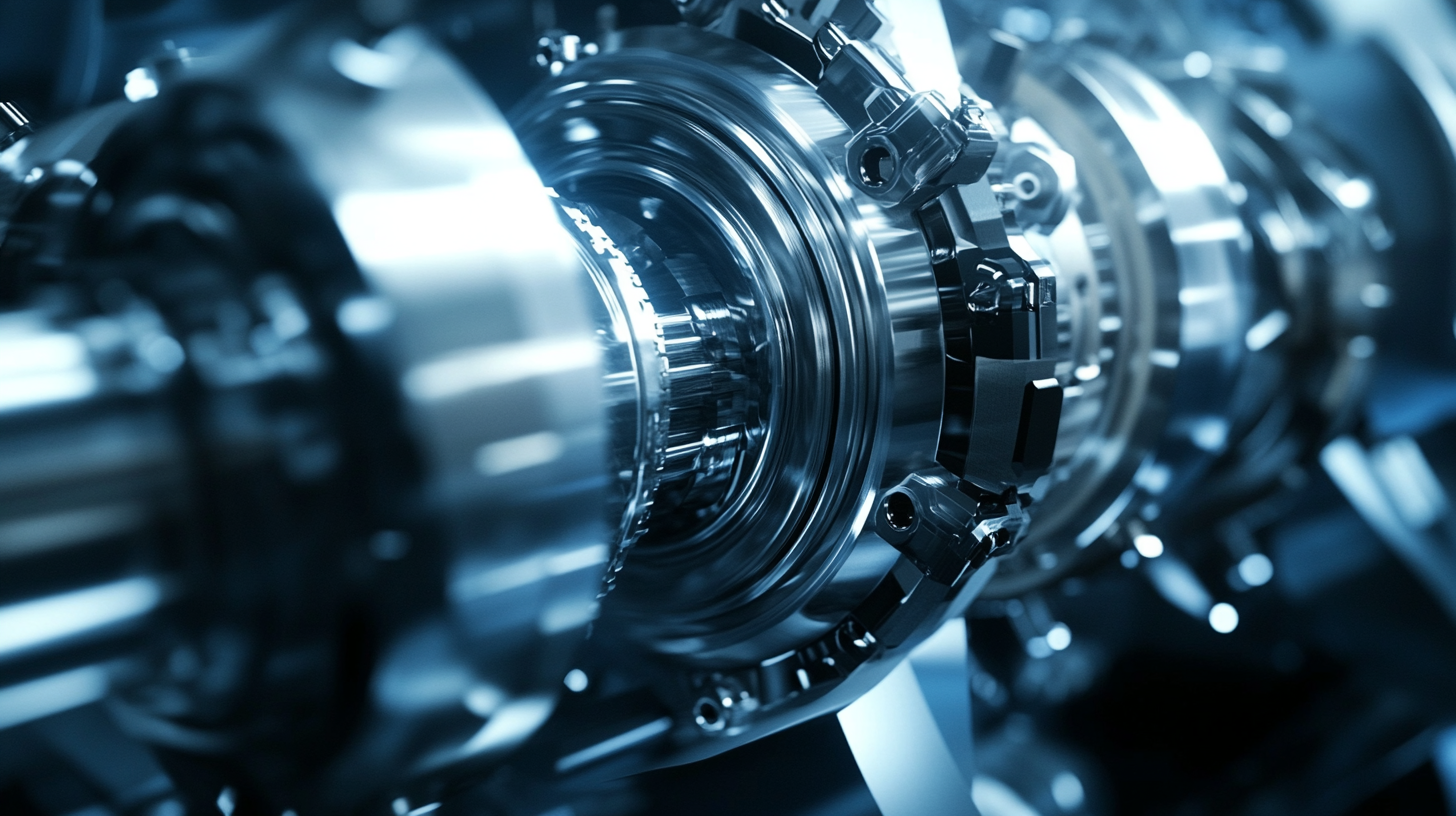

The Evolution of Hydraulic Pump Technology in Global Industries

The evolution of hydraulic pump technology has significantly transformed global industries, enhancing productivity and efficiency across various sectors. Initially, hydraulic systems were limited to basic applications, often relying on outdated mechanical components. However, with advancements in engineering and materials science, modern hydraulic pumps are now equipped with advanced features such as variable speed control, improved energy efficiency, and increased durability. These enhancements allow manufacturers to optimize their operations, reducing energy consumption while maximizing output.

One notable aspect of this evolution is the integration of smart technology into hydraulic systems. IoT-enabled sensors and automation systems are now commonplace, allowing for real-time monitoring and diagnostics. This shift not only facilitates predictive maintenance but also enables companies to quickly respond to system inefficiencies. As a result, industries such as construction, manufacturing, and agriculture are reaping the benefits of this technological leap, improving overall operational workflows and ensuring a sustainable approach to resource management.

Moreover, the push toward eco-friendly solutions has driven innovations in hydraulic pump design. Manufacturers are increasingly prioritizing the development of pumps that minimize environmental impact, such as those that utilize biodegradable fluids or require less energy in operation. This focus on sustainability reflects a broader commitment within the global marketplace to adopt greener technologies, aligning industrial growth with environmental stewardship. As hydraulic pump technology continues to evolve, its role in driving efficiency and sustainability in global industries will undoubtedly expand further.

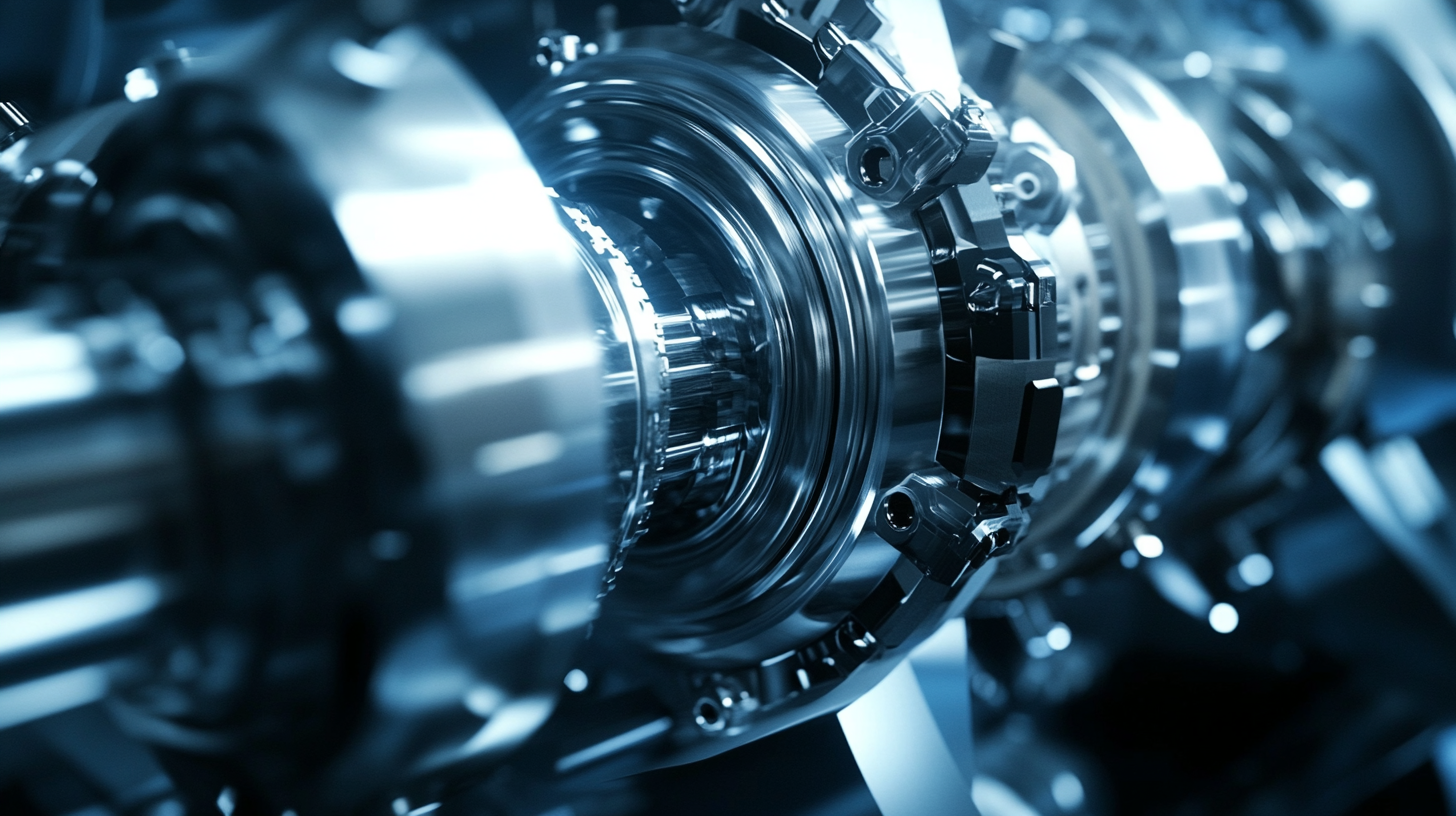

Key Benefits of Advanced Hydraulic Pump Solutions for Efficiency

In today's fast-paced industrial landscape, the integration of advanced hydraulic pump solutions is crucial for enhancing efficiency across various sectors. As industries strive to optimize their operations, hydraulic systems that incorporate modern technologies—such as sensors and advanced motor configurations—are proving invaluable. These innovations not only reduce operational costs but also improve the overall performance of hydraulic systems, making them more responsive and adaptable to the dynamic needs of modern manufacturing.

The adoption of intelligent control algorithms is another significant advancement that stands to transform the hydraulic pump market. By leveraging data-driven insights, companies can now fine-tune their systems for peak performance, enabling real-time adjustments and reducing waste. This level of precision not only enhances energy efficiency but also contributes to sustainability efforts within the industry. Furthermore, the increasing use of metal 3D printing in producing hydraulic components offers greater design flexibility, allowing for more efficient use of materials and the creation of intricate geometries that were previously impractical.

As we move towards a more interconnected industrial future, the benefits of advanced hydraulic pump solutions will become increasingly apparent. The synergy between electric motor technology and hydraulic systems exemplifies this trend, showcasing how these innovations collectively lead to greater operational efficiencies. Companies investing in these cutting-edge solutions are positioning themselves at the forefront of their industries, ready to capitalize on the efficiencies and competitive advantages they offer.

Case Studies: Transforming Operations with Innovative Hydraulic Pumps

In the ever-evolving landscape of global industries, hydraulic pump solutions have emerged as pivotal in streamlining operations and enhancing productivity. A shining example is seen in the oil and gas sector, particularly in the case study of Bien Dong Petroleum Operating Company (POC). This organization embarked on a digital transformation journey, leveraging advanced hydraulic pump technologies to optimize its operational efficiency.

The integration of innovative hydraulic pumps at Bien Dong POC has led to significant improvements in their extraction processes. By adopting smart pump systems equipped with real-time monitoring capabilities, the company achieved greater control over pump performance, which resulted in reduced downtime and maintenance costs. This technological upgrade not only facilitated enhanced productivity but also contributed to safer working environments by minimizing the risks associated with pump failures.

Moreover, the implementation of these advanced hydraulic solutions allowed for seamless interoperability with other digital tools, streamlining data flow across operations. This interconnectedness enabled Bien Dong POC to make data-driven decisions that further improved their operational strategies. As industries continue to embrace digital transformation, the successful case of Bien Dong POC serves as a compelling testament to the transformative power of innovative hydraulic pump solutions in driving efficiency and productivity on a global scale.

Future Trends in Hydraulic Pump Development and Industry Impact

The hydraulic pump industry is undergoing significant transformations, driven by technological advancements and increasing demand across global sectors. As noted in recent market analyses, the hydraulic and pneumatic machinery manufacturing sector in China is transitioning from a growth phase to a more mature stage, having benefited from the introduction of over 60 foreign technologies since the 1980s. This influx of innovation has not only enhanced operational efficiency but has also paved the way for sophisticated hydraulic solutions that are crucial for industries such as construction and mining.

Current reports indicate that the hydraulic pump market is expected to see substantial growth in the coming years, fueled by the expanding construction industry and the rising need for energy-efficient machines. A notable trend is the integration of smart technologies into hydraulic systems, which facilitates predictive maintenance and reduces operational downtimes. Furthermore, the demand for lower energy consumption and enhanced performance is prompting companies to focus on R&D initiatives that highlight eco-friendly designs and reduced lifecycle costs.

Emerging players in the hydraulic pump sector are also stepping up to meet these challenges, offering innovative products tailored to the evolving needs of the market. Enhanced durability and reliability are becoming key differentiators in this competitive landscape, as industry leaders strive to offer solutions that not only meet regulatory standards but also exceed customer expectations. As this sector evolves, embracing new technologies will undoubtedly be central to sustaining growth and achieving long-term efficiency in hydraulic pump applications worldwide.

Integrating Smart Technology with Hydraulic Pumps for Enhanced Performance

The integration of smart technology with hydraulic pumps is revolutionizing the operational efficiency of global industries. According to a report by MarketsandMarkets, the global smart hydraulic systems market is projected to grow from USD 2.3 billion in 2020 to USD 4.1 billion by 2025, at a compound annual growth rate (CAGR) of 12.2%. This rapid growth is driven by the increasing need for automation and real-time monitoring in various sectors, including construction, manufacturing, and agriculture. Advanced hydraulic pumps equipped with smart technology can provide real-time data on performance, allowing for proactive maintenance and minimizing downtime.

Smart hydraulic pumps utilize sensors and IoT (Internet of Things) connectivity to collect and analyze data during operation. This data can inform operators about potential issues before they escalate into costly failures. For instance, predictive maintenance techniques can reduce unexpected equipment failures by up to 30%, as highlighted in a study by Deloitte. By optimizing the maintenance schedules of hydraulic systems, industries can significantly increase their productivity and potentially save thousands of dollars in repairs and operational disruptions.

In addition to maintenance benefits, the integration of smart technology enhances the overall performance of hydraulic pumps. By optimizing the flow dynamics and energy consumption, these advanced solutions can reduce operational costs by 10-25%, according to a study from the Hydraulic Institute. As industries continue to seek out ways to improve efficiency and reduce costs, the adoption of smart hydraulic pump solutions stands poised to play a critical role in the future of global manufacturing and production.