Innovative Solutions for Efficient Hydraulic Pumps and Motors in Global Markets

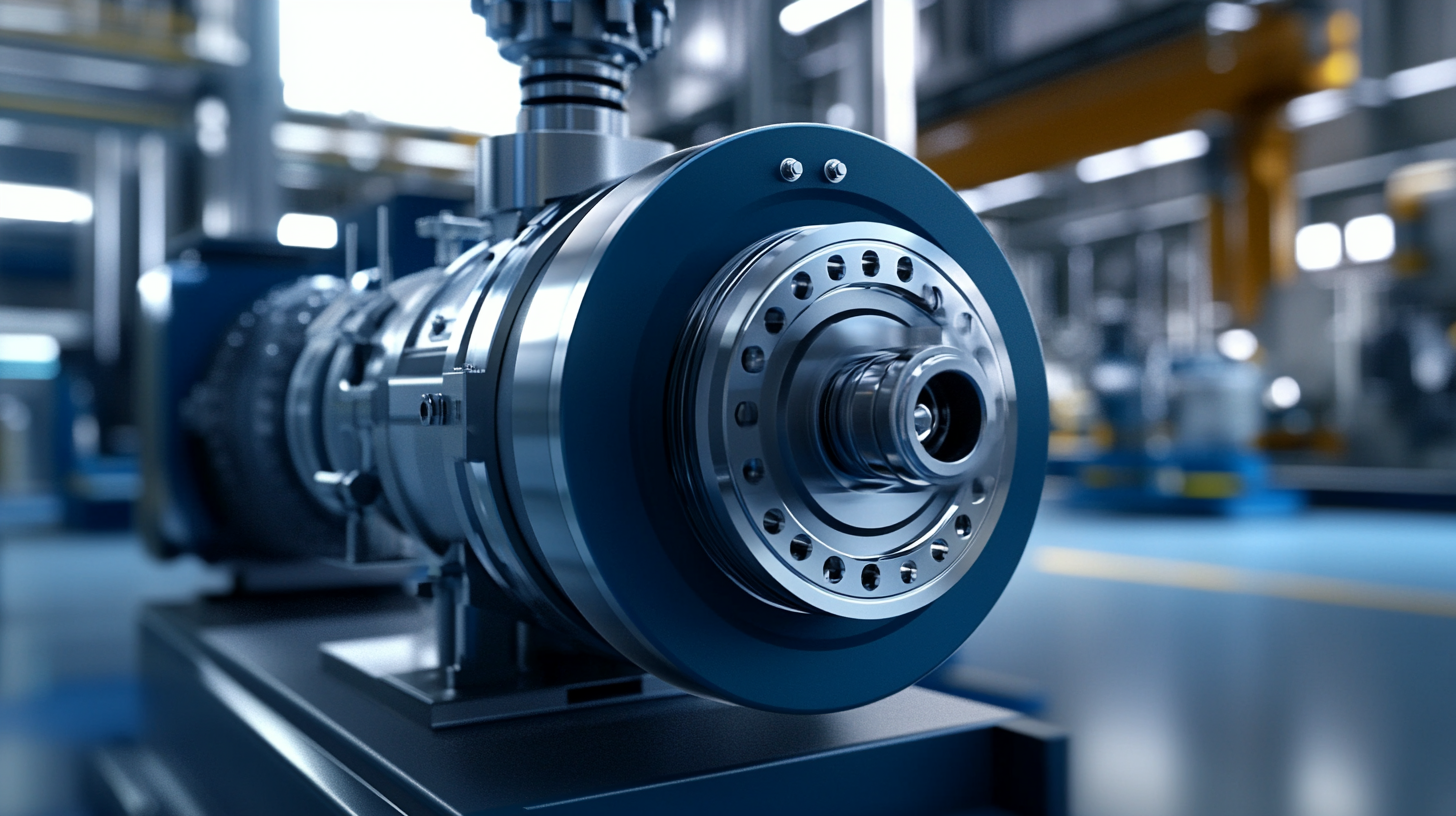

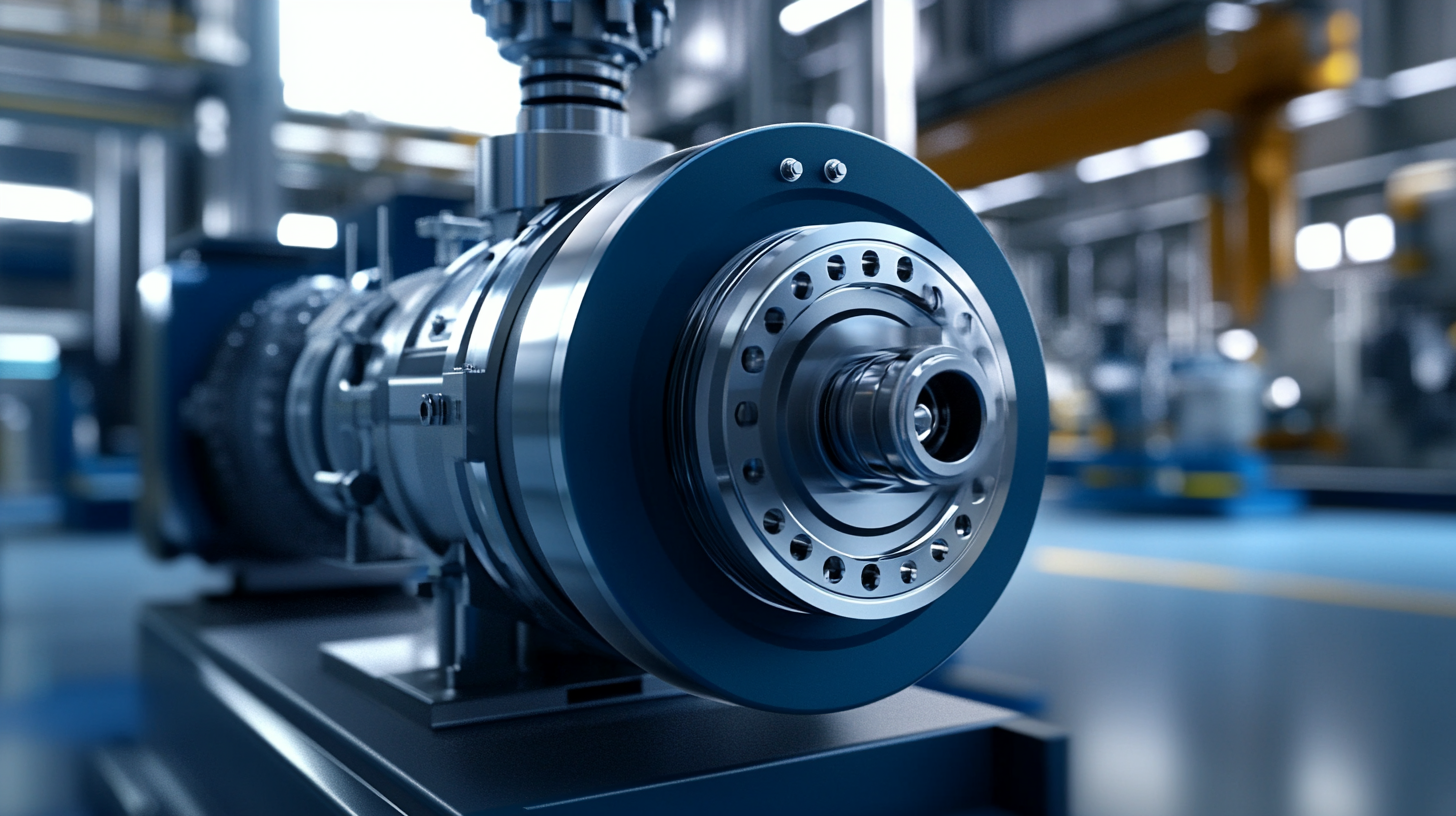

In the rapidly evolving landscape of industrial technology, the role of hydraulic pumps and motors is more pivotal than ever. These essential components power a wide range of machinery across various sectors, demonstrating their importance in driving efficiency and performance. As global markets expand and become increasingly competitive, the demand for innovative solutions that enhance the functionality and reliability of hydraulic systems has surged. This need has sparked a wave of advancements in hydraulic pump and motor technologies, aimed at optimizing performance while minimizing energy consumption and environmental impact.

The pursuit of efficiency in hydraulic pumps and motors is not just a technical challenge; it also presents significant economic opportunities. Companies worldwide are looking to leverage cutting-edge innovations to streamline operations and reduce costs. From smart hydraulic systems that integrate IoT technology to novel materials that enhance durability, the latest trends are shaping the future of hydraulic machinery. This blog will explore the innovative solutions emerging within the industry, highlighting their potential to transform hydraulic pumps and motors into more efficient, sustainable, and reliable power sources for global markets.

Current Trends in Hydraulic Pump and Motor Technologies

In recent years, the hydraulic pump and motor industry has witnessed significant advancements driven by the demand for more efficient and environmentally friendly solutions. According to a report by MarketsandMarkets, the global hydraulic pumps market is expected to reach USD 16.17 billion by 2026, growing at a CAGR of 5.3%. This growth is predominantly fueled by the increasing adoption of hydraulic systems in various sectors, including construction, manufacturing, and agriculture, where high efficiency and reliability are paramount.

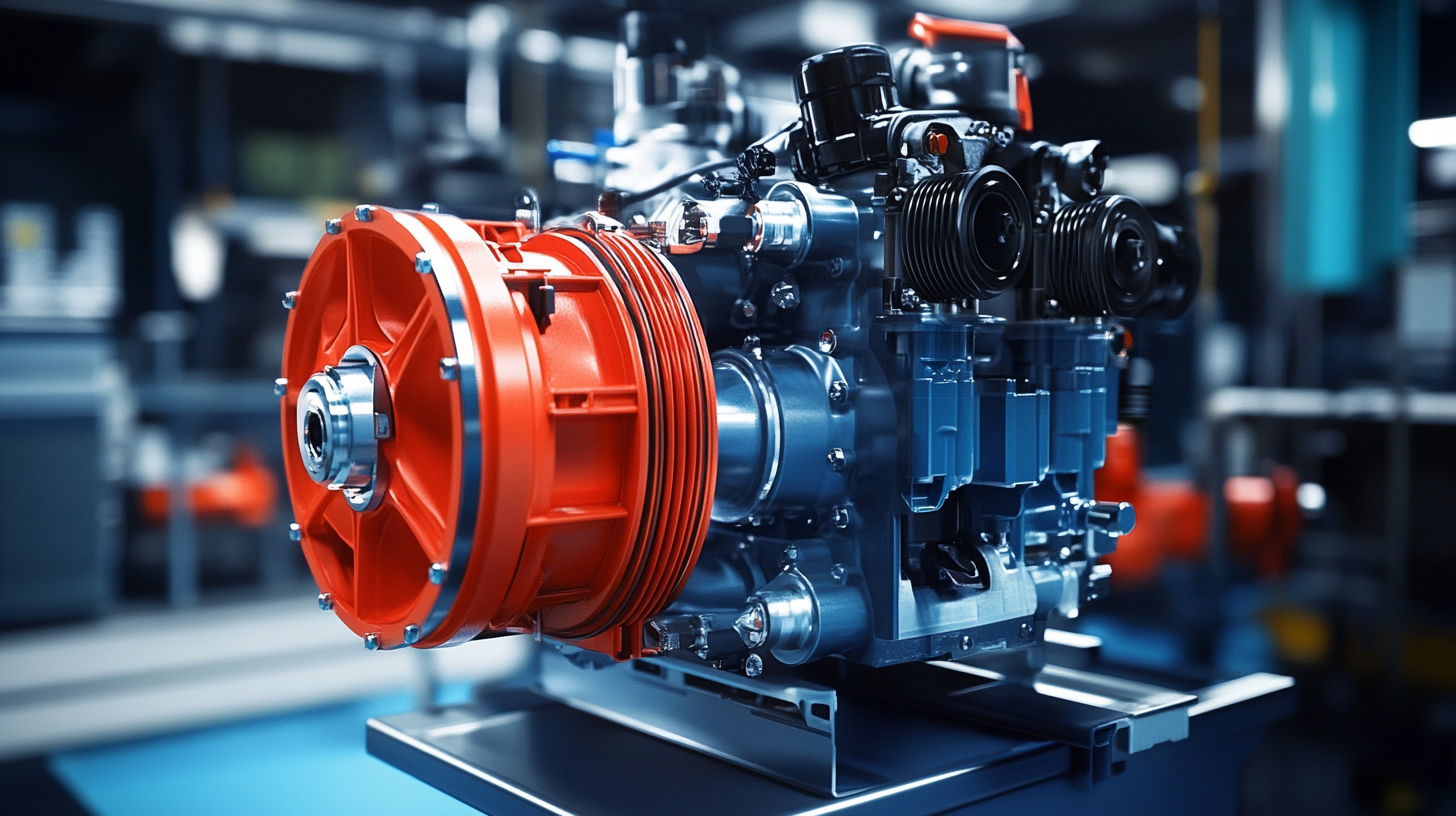

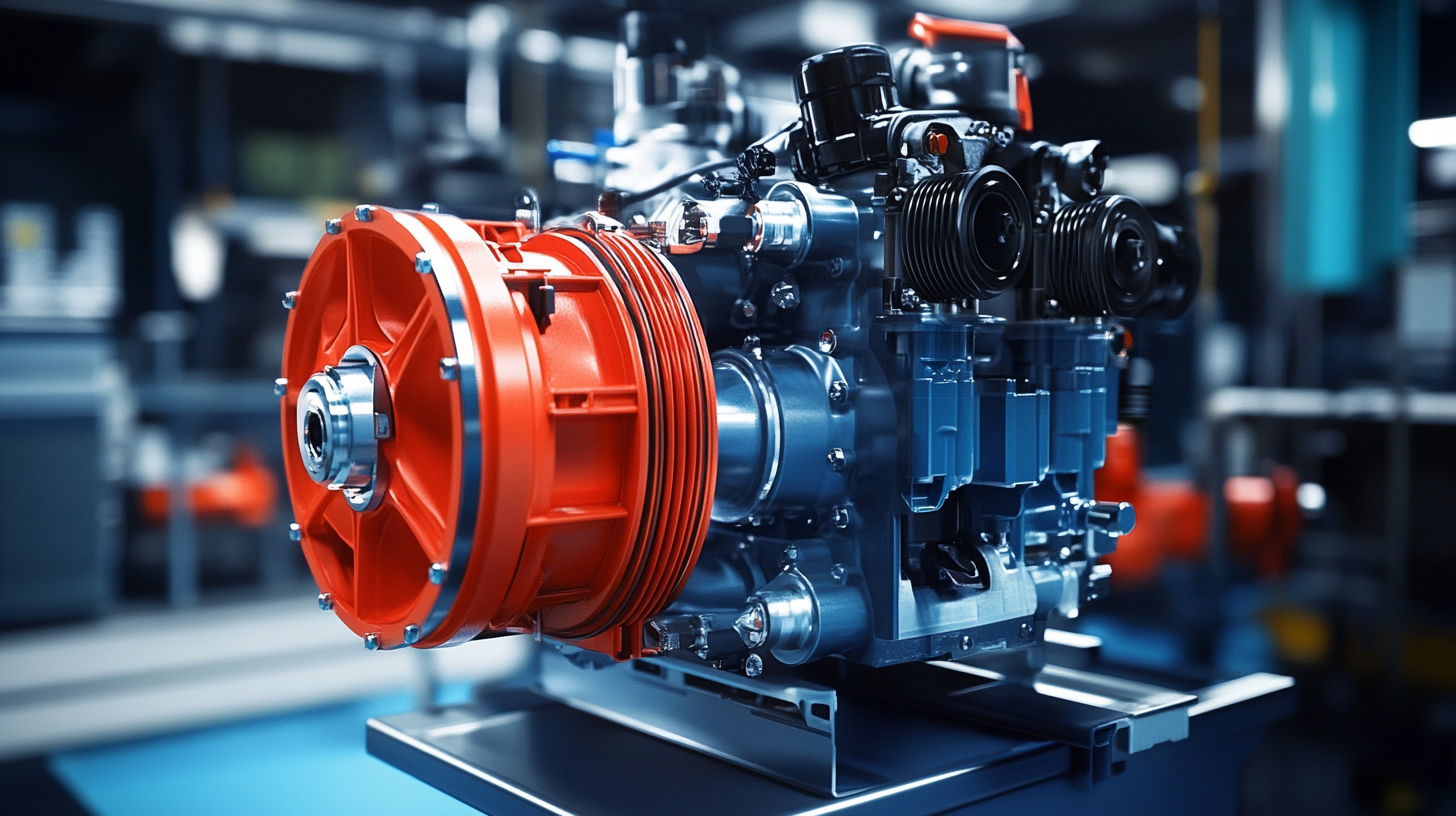

Current trends in hydraulic technology highlight the shift towards electric and hybrid hydraulic systems. These innovations not only reduce energy consumption but also minimize greenhouse gas emissions. For instance, several manufacturers are now integrating smart technology and IoT capabilities into hydraulic systems, enabling real-time monitoring and predictive maintenance. According to a recent study by ResearchAndMarkets, the integration of IoT in hydraulic machinery can lead to up to a 30% increase in operational efficiency, demonstrating the significant potential of these technologies in enhancing performance.

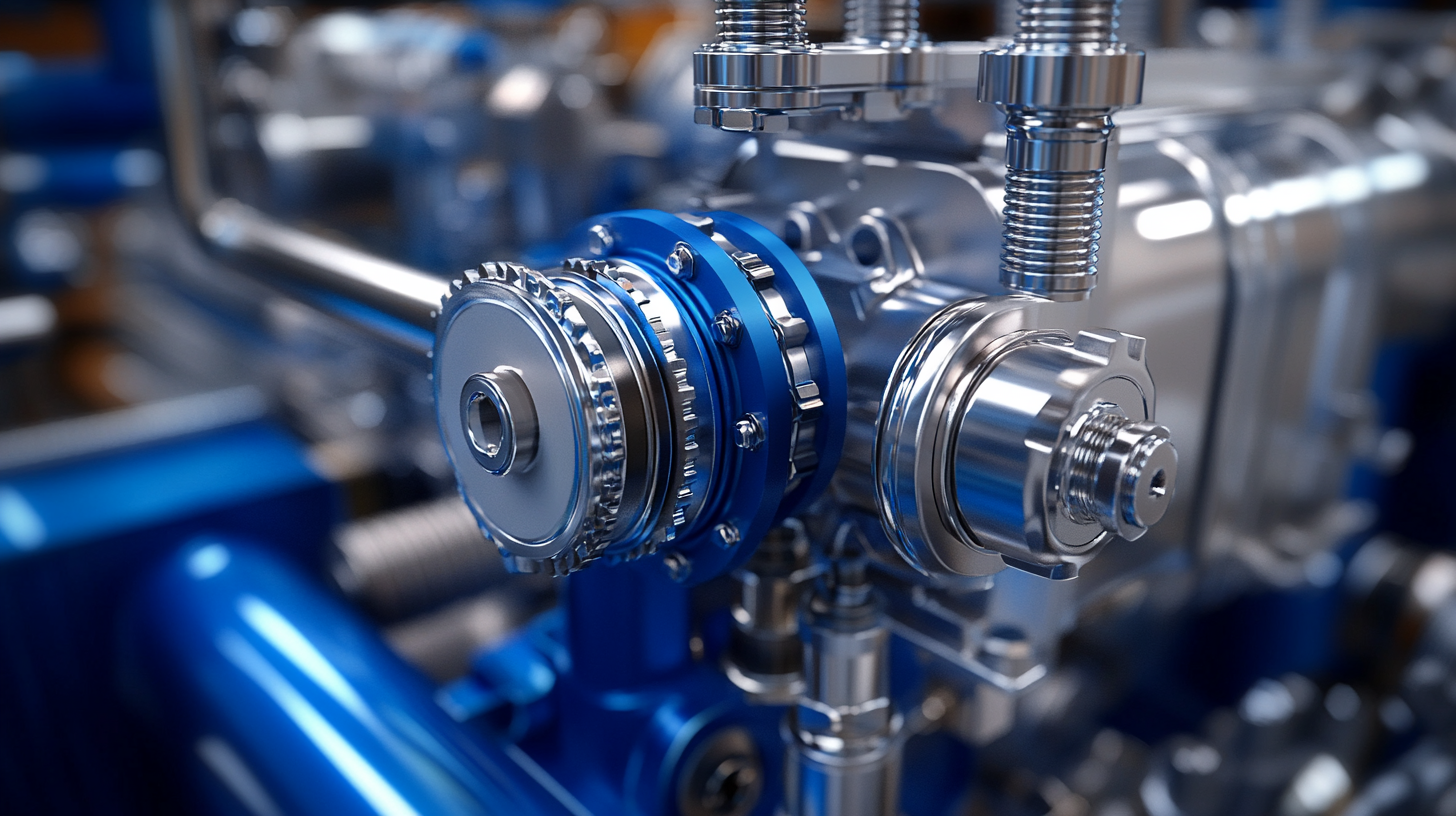

Moreover, advancements in material science have resulted in the development of more durable and lightweight hydraulic components. The introduction of advanced composites and high-strength alloys has improved the lifespan and performance of hydraulic pumps and motors, making them suitable for even the most demanding applications. As industries increasingly focus on sustainability, these innovations not only drive performance but also align with environmental objectives, positioning hydraulic technology for a transformative future in global markets.

Challenges in Global Hydraulic Systems and Market Adaptation

In the rapidly evolving landscape of hydraulic systems, companies face numerous challenges while adapting to global markets. The complexity of integrating advanced technologies, such as X-by-wire systems, is reshaping how hydraulic pumps and motors operate within these frameworks. According to recent industry reports, the global hydraulic pumps market is projected to reach $15 billion by 2027, driven largely by innovations in automation and demand for efficiency in various sectors, including automotive and industrial applications.

As the push for automated driving technologies grows, the emphasis on adaptable hydraulic solutions intensifies. Companies must navigate issues related to supply chain disruptions, fluctuating raw material prices, and increasingly stringent regulatory requirements. The successful adaptation to these challenges requires a strategic focus on innovation and sustainability. Reports indicate that the integration of smart hydraulic systems can improve efficiency by up to 30%, highlighting the critical role that forward-thinking companies play in setting new industry standards.

In this context, the future of hydraulic systems looks towards enhanced integration with digital technologies, enabling real-time monitoring and control. Moreover, adaptability in design and manufacturing processes will be essential for meeting the diverse needs of global markets. As players in this field continue to innovate, they pave the way for more efficient and sustainable solutions that support the burgeoning demand for automated systems.

Innovative Design Approaches for Enhanced Performance

In the rapidly evolving landscape of hydraulic pumps and motors, innovative design approaches are crucial for enhancing performance and efficiency. One significant trend is the integration of advanced materials and technologies that reduce weight while increasing strength. For example, using composite materials not only enhances durability but also improves energy transfer, allowing systems to operate with higher efficiency. The adoption of lightweight designs enables manufacturers to create more compact hydraulic systems, which is particularly beneficial in sectors where space and weight limitations are stringent.

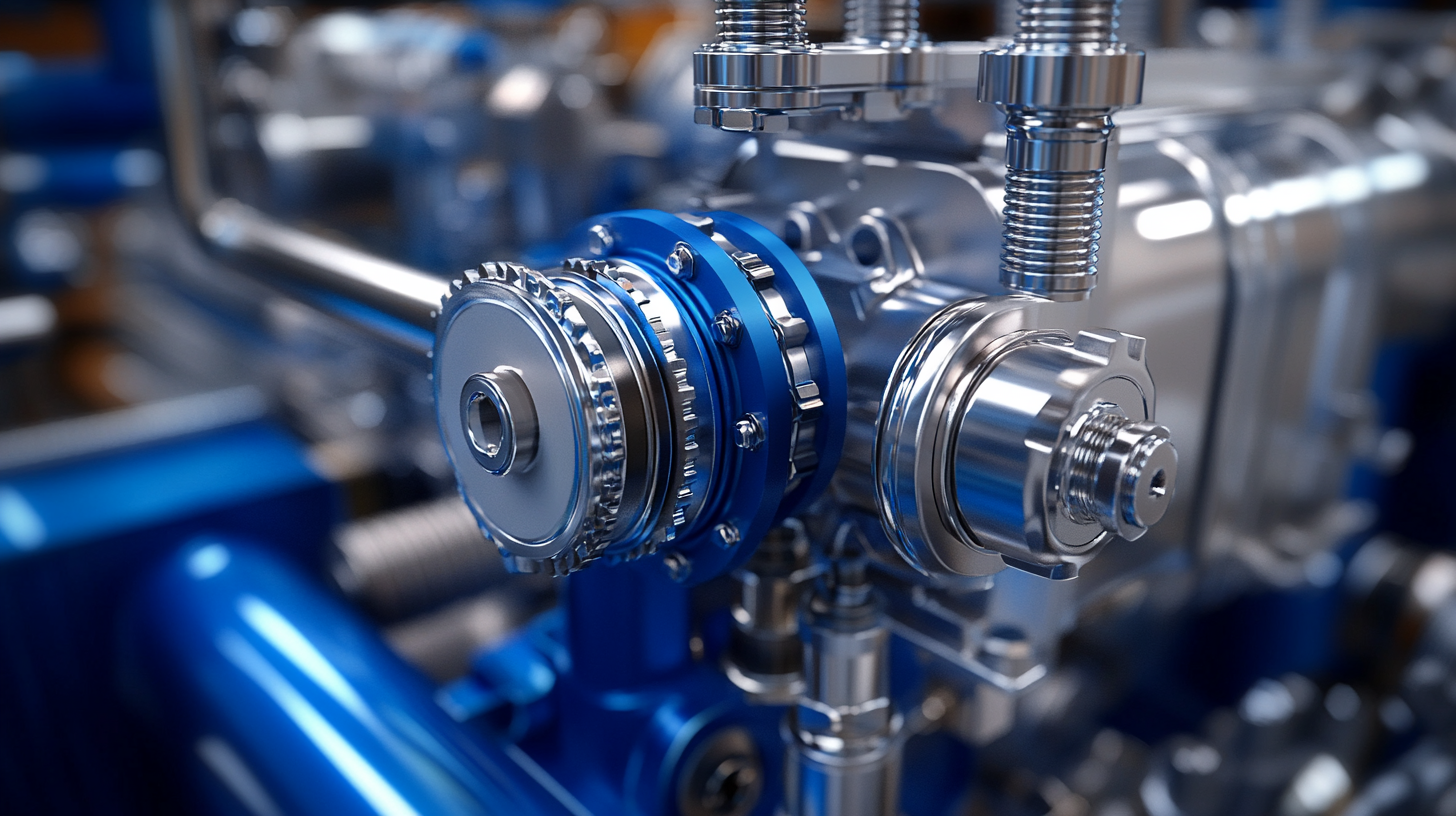

Moreover, the implementation of smart technologies plays a pivotal role in optimizing the performance of hydraulic pumps and motors. By incorporating sensors and IoT capabilities, these systems can monitor various parameters in real time, such as pressure and temperature. This data allows for predictive maintenance, minimizing downtime and operational costs. Additionally, enhanced control algorithms provide more precise operation, adapting to changing conditions and reducing energy consumption significantly.

Another innovative approach is the development of modular designs. These systems allow for easy customization and scalability, enabling companies to respond effectively to market demands. By utilizing modular components, manufacturers can quickly adapt their products to different applications or replace parts without having to overhaul entire systems. This flexibility not only improves performance but also fosters sustainability by extending the lifespan of hydraulic equipment through easier maintenance and upgrades.

Sustainability and Eco-Friendly Practices in Hydraulic Systems

In the rapidly evolving landscape of hydraulic systems, sustainability and eco-friendly practices have emerged as pivotal considerations for manufacturers and users alike. With the global hydraulic market projected to reach $54.7 billion by 2025, as reported by market analysis firms, the emphasis on energy efficiency and reduced environmental impact is more crucial than ever. The introduction of innovative hydraulic pumps and motors that integrate eco-friendly technologies can significantly minimize energy consumption, aligning with the increasing regulatory pressure toward greener solutions.

One promising development in this domain is the adoption of bio-based hydraulic fluids, which not only comply with stringent environmental regulations but also enhance safety in various applications. According to a study by the American Society of Mechanical Engineers, companies using biodegradable hydraulic fluids noticed a 15% reduction in environmental incidents related to fluid leaks. Such advancements not only protect ecosystems but also boost companies' sustainability profiles, making them more appealing to environmentally conscious consumers and regulators.

Moreover, the integration of smart technologies into hydraulic systems is revolutionizing maintenance practices. According to a report by the Hydraulic Institute, systems equipped with predictive maintenance capabilities can reduce downtime by up to 30%. This efficiency not only drives productivity but also minimizes waste generated from premature equipment failures. By focusing on sustainable practices, industries can foster a circular economy, ensuring that hydraulic systems are not only efficient but also contribute positively to the environment.

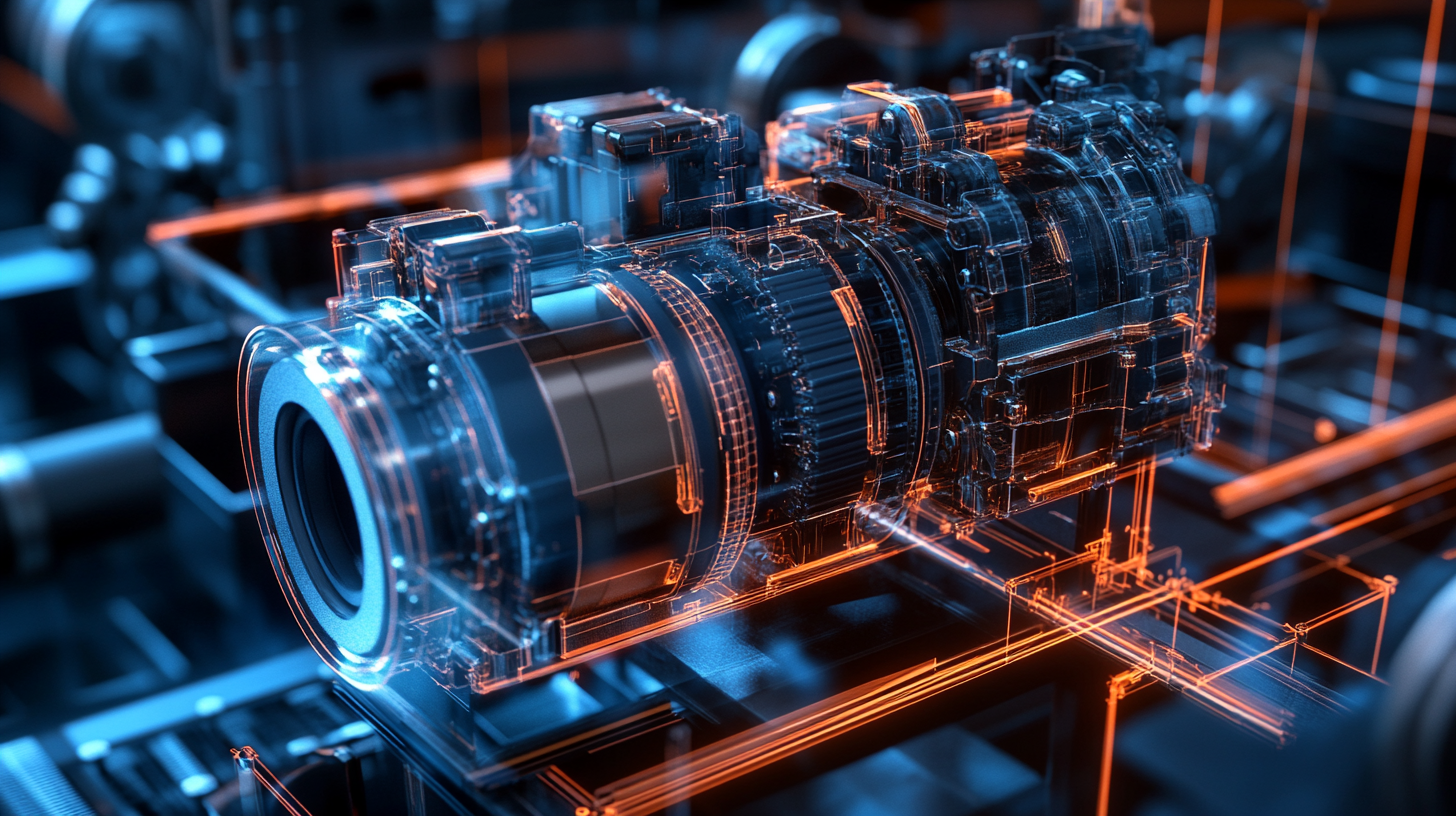

Future Directions: Integrating Smart Technologies in Hydraulic Solutions

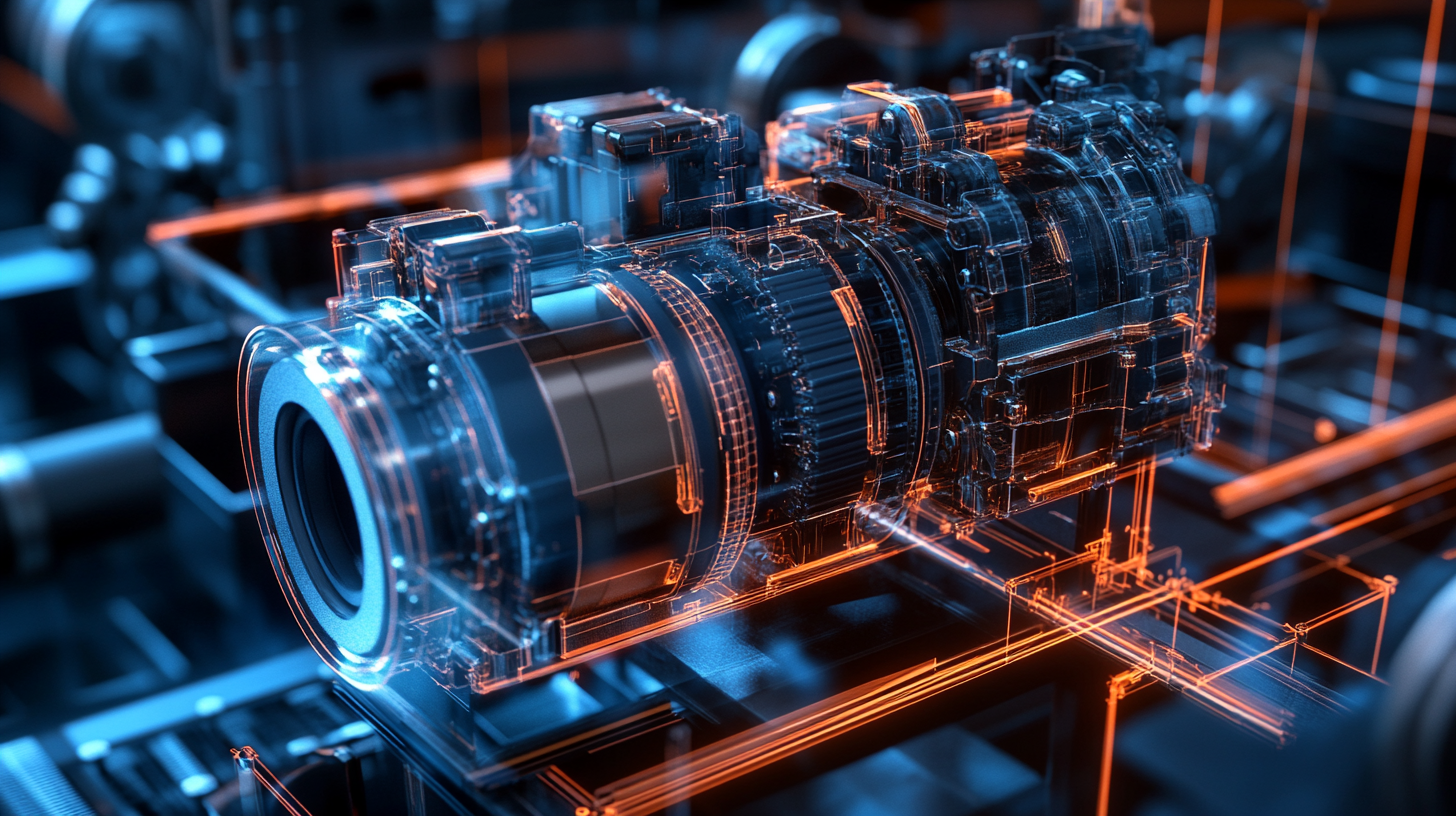

The integration of smart technologies within hydraulic solutions marks a significant leap towards enhancing operational efficiency in global markets. As industries increasingly adopt automation, the traditional hydraulic pumps and motors are evolving to incorporate intelligent functionalities that streamline processes and reduce waste. Smart sensors and data analytics are now being embedded within hydraulic systems, allowing for real-time monitoring and predictive maintenance. This not only enhances the reliability of hydraulic machinery but also minimizes downtime, ultimately leading to substantial cost savings for companies.

Furthermore, the adaptation of IoT (Internet of Things) in hydraulic solutions enables seamless connectivity and communication between devices. This interconnectivity allows operators to analyze performance data, detect anomalies, and optimize workflows. For instance, hydraulic systems equipped with smart technology can autonomously adjust their operation based on workload demands, improving energy efficiency and prolonging equipment life. As industries push towards sustainability, the role of smart technologies in hydraulic solutions will be pivotal in achieving eco-friendly operational goals.

In addition to efficiency gains, the incorporation of smart technologies can lead to enhanced safety within hydraulic systems. By utilizing advanced monitoring systems, potential risks can be identified and mitigated before they escalate into more significant issues. This proactive approach not only protects equipment but also ensures the safety of personnel working in high-risk environments. As hydraulic solutions continue to evolve, the future will undoubtedly be shaped by the synergistic integration of innovation and intelligence, paving the way for smarter, safer, and more efficient operations worldwide.