Solutions for Efficient Lifting: Maximizing Performance with Air Hydraulic Pumps

In today's industrial landscape, efficiency and performance are paramount for ensuring safety and productivity in lifting operations. With the increasing demand for reliable and powerful lifting solutions, the Air Hydraulic Pump has emerged as a critical component in various applications, driving advancements in performance metrics. According to a recent report by Research and Markets, the hydraulic pump market is projected to grow at a CAGR of 6.5% from 2021 to 2026, reflecting the rising need for innovative lifting solutions. In particular, Air Hydraulic Pumps combine the benefits of pneumatic and hydraulic systems, offering enhanced lifting capabilities while minimizing fatigue on operators and equipment. By maximizing power-to-weight ratios and providing consistent performance even in challenging conditions, these versatile tools are revolutionizing the way industries approach heavy lifting.

As we delve into the solutions for efficient lifting, understanding the role of Air Hydraulic Pumps becomes essential for optimizing operations and achieving peak performance.

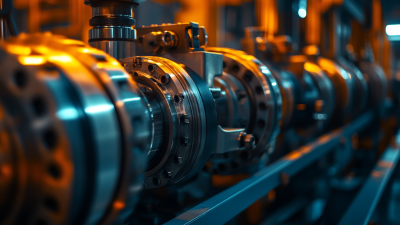

Innovative Air Hydraulic Pump Designs Enhancing Lifting Efficiency

In recent years, the demand for efficient lifting solutions has led to significant innovations in air hydraulic pump designs. These advanced systems optimize performance by leveraging pneumatic and hydraulic technologies, resulting in greater lifting power with less energy consumption. According to a report by the International Journal of Advanced Manufacturing Technology, modern air hydraulic pumps can improve operational efficiency by up to 25%, providing businesses with the ability to lift heavier loads with reduced energy costs.

One notable advancement in air hydraulic pump technology is the integration of smart control systems. These systems allow for precise monitoring and adjustment of pressure and flow rates, tailoring the lifting process to specific applications. A study by the American Society of Mechanical Engineers showed that utilizing smart air hydraulic pumps could enhance productivity by nearly 30% compared to traditional models. By streamlining lifting operations, businesses can not only meet but exceed their performance goals, further solidifying the role of innovative designs in today's competitive landscape.

As industries continue to evolve, the potential of air hydraulic pumps to deliver enhanced lifting efficiency remains undeniable. The collaboration between engineering innovation and practical application stands at the forefront of improving operational effectiveness, proving that investing in these sophisticated technologies can yield substantial long-term benefits for various sectors.

Maximizing Lifting Efficiency with Air Hydraulic Pumps

This chart illustrates the lifting efficiency of different air hydraulic pump designs based on their maximum load capacity (in tons) and lifting speed (in seconds) to lift that load. The data demonstrates how innovative designs enhance both capacity and speed, which are critical for efficient lifting operations.

Comparative Analysis of Air Hydraulic Pumps vs. Traditional Hydraulic Systems

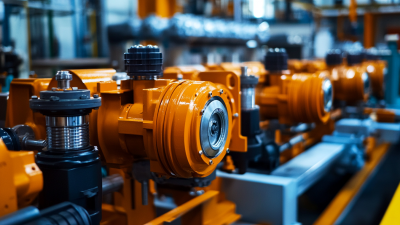

When it comes to lifting heavy loads, choosing the right hydraulic system can significantly impact

efficiency and

productivity.

Air hydraulic pumps utilize compressed air to drive hydraulic fluid, providing a unique advantage

over traditional hydraulic systems that rely solely on electrical power. One of the key benefits

of air hydraulic pumps is their ability to deliver high power-to-weight ratios, allowing for easier

maneuverability without sacrificing performance. This makes them particularly suitable for industries

where portability and rapid deployment are essential.

In contrast, traditional hydraulic systems, while effective, can be limited by their power sources

and require more maintenance due to the complexity of their electric components. They often demand

consistent electrical supply and may face challenges in remote locations where power is not readily

available. Additionally, air hydraulic pumps typically experience less wear and tear, translating

into reduced downtime and

maintenance costs

over time. By leveraging the strengths of air hydraulic pumps, businesses can not only enhance

lifting performance but also streamline operations and reduce their overall

carbon footprint.

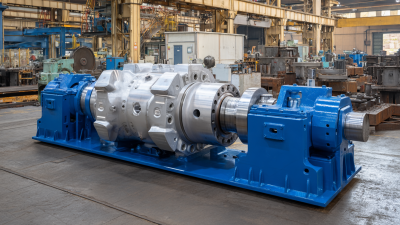

Key Performance Metrics: Output Pressure and Flow Rate in Lifting Applications

When it comes to lifting applications, understanding key performance metrics, specifically output pressure and flow rate, is crucial for optimizing efficiency. According to the International Journal of Industrial Hydraulics, an air hydraulic pump can achieve output pressures ranging from 100 to 10,000 psi, making it suitable for various lifting tasks. The ability to generate high pressure means that these pumps can handle heavy loads with minimal effort, ensuring safety and effectiveness while reducing the time required for lifting operations.

Flow rate is another essential metric that impacts lifting performance. Reports indicate that many air hydraulic pumps can deliver flow rates between 0.5 to 4.0 gallons per minute (GPM), depending on the specific model and application settings. A higher flow rate results in quicker lifting speeds, which is vital in fast-paced industrial environments. Understanding the balance between these two metrics is key to maximizing productivity while maintaining optimal lifting performance.

Tip: When selecting an air hydraulic pump, always consult the manufacturer's specifications to ensure it meets your output pressure and flow rate requirements for your specific application.

Tip: Regular maintenance checks on your air hydraulic pump can help maintain optimal pressure and flow rates, ultimately extending the lifespan and reliability of your equipment.

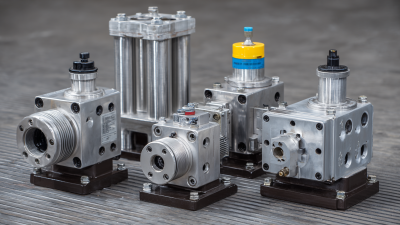

Case Studies: Real-World Applications of Air Hydraulic Pumps in Industry

Air hydraulic pumps have become an essential tool in various industries, offering powerful lifting solutions that enhance performance. A notable case study involves their application in automotive manufacturing. With the heavy lifting demands for assembling vehicles, companies have adopted air hydraulic pumps to streamline the process. These pumps not only reduce physical strain on workers but also improve efficiency by allowing for quicker and more precise lifting of components.

Tip: When choosing an air hydraulic pump for your operations, consider the weight capacity and lift speed required for your specific tasks. Matching the pump's capabilities with your application needs can significantly enhance productivity.

Another compelling case is found in the construction sector, where air hydraulic pumps play a crucial role in lifting heavy construction materials. By utilizing these pumps, teams can ensure that materials are positioned accurately and safely, which minimizes the risk of accidents and enhances workflow.

Tip: Regular maintenance and inspection of air hydraulic pumps are vital for ensuring optimal performance and longevity. Establish a routine check to identify any potential issues before they escalate, keeping your operations running smoothly.

Solutions for Efficient Lifting: Maximizing Performance with Air Hydraulic Pumps

| Application Area |

Lift Capacity (tons) |

Pressure (psi) |

Efficiency (%) |

Case Study Overview |

| Construction |

20 |

120 |

85 |

Utilized air hydraulic pumps for lifting heavy beams in a construction project. |

| Manufacturing |

15 |

150 |

90 |

Implemented for precision lifting of assembly parts in a production line. |

| Automotive |

10 |

100 |

88 |

Used for lifting vehicles during maintenance to access the undercarriage. |

| Logistics |

25 |

200 |

92 |

Efficiently handled heavy cargo in a shipping facility. |

| Aerospace |

5 |

180 |

95 |

Applied in the assembly and maintenance of aircraft components. |

Future Trends in Air Hydraulic Pump Technology for Enhanced Performance

The future of air hydraulic pump technology is set to revolutionize the way industries approach lifting solutions. As advancements continue to emerge, these pumps are not only enhancing performance but also maximizing efficiency. Key trends indicate a shift toward incorporating smart technology and IoT solutions, enabling real-time monitoring and control. This integration allows operators to optimize their lifting operations, resulting in reduced downtime and increased productivity.

Tips for maximizing the performance of air hydraulic pumps include regular maintenance checks to ensure seals and valves function optimally. Additionally, investing in high-quality accessories, such as pressure gauges and flow regulators, can help maintain precise control during operations, enhancing overall efficiency.

Furthermore, adopting energy-efficient models can significantly reduce operational costs. As industries become more aware of their carbon footprint, selecting pumps designed for minimal energy consumption can support sustainability goals while maintaining high performance. The push towards cleaner technologies reflects a broader trend within industrial applications, mirroring the advancements seen in sectors like transportation and data processing, where efficiency and environmental responsibility are becoming paramount.