Understanding the Essential Functions of Hydraulic Pressure Pumps

In the realm of industrial machinery, understanding the essential functions of hydraulic pressure pumps is critical for maintaining operational efficiency. With the global hydraulic pump market expected to reach approximately $12.6 billion by 2028, driven by advancements in construction and manufacturing sectors, the role of hydraulic pressure pumps has never been more significant. These pumps are vital for transferring energy through fluids and thus are integral to heavy equipment and automated systems. However, various types of hydraulic pressure pumps can encounter specific operational problems, including inefficiencies, pressure drops, and leaks, which can severely impact productivity and safety. Identifying and addressing these issues is fundamental for optimizing hydraulic systems and ensuring seamless workflows across industries.

Key Components of Hydraulic Pressure Pumps and Their Functions

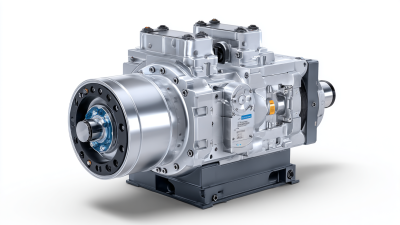

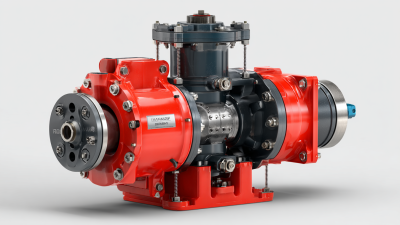

Hydraulic pressure pumps play a crucial role in a variety of industrial and mobile applications, relying on a few essential components to function effectively. The most important of these is the pump itself, which converts mechanical energy into hydraulic energy by compressing fluid. This process is typically facilitated by either gear, vane, or piston technology, each offering unique advantages to suit different operational requirements. The choice of pump type is determined by factors such as desired pressure levels, flow rates, and the nature of the hydraulic fluid.

Another key component is the hydraulic reservoir, which stores the hydraulic fluid. This reservoir not only supplies the pump but also helps to dissipate heat, allowing for efficient operation of the hydraulic system. Additionally, hydraulic filters are vital for removing contaminants from the fluid, ensuring that the system runs smoothly and is protected from wear and tear. Finally, pressure relief valves are critical in maintaining system safety by preventing excessive pressure buildup that could lead to system failures. Understanding these components and their functions is essential for optimizing the performance and reliability of hydraulic systems.

Types of Hydraulic Pressure Pumps: A Comprehensive Overview

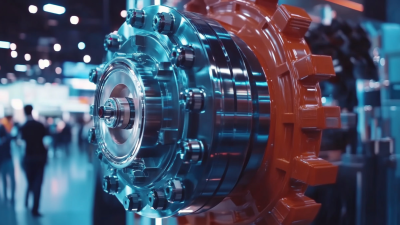

Hydraulic pressure pumps are key components in various industrial and machinery applications, facilitating the movement of fluids through a hydraulic system. Understanding the different types of hydraulic pressure pumps is crucial for selecting the right one for specific requirements. There are primarily two categories of hydraulic pumps: positive displacement pumps and non-positive displacement pumps.

Positive displacement pumps, including gear pumps, vane pumps, and piston pumps, are known for their ability to deliver a consistent flow rate, regardless of the system's pressure. Gear pumps are widely used for their simplicity and efficiency in applications requiring moderate flow rates. Vane pumps are versatile and can handle high pressures, making them suitable for diverse applications. Piston pumps, on the other hand, excel in high-pressure scenarios and are ideal for demanding requirements.

Non-positive displacement pumps, such as centrifugal pumps, operate differently. They rely on kinetic energy to transfer fluid, making them more suitable for large volume applications with lower pressure requirements. Centrifugal pumps are common in systems where continuous flow is necessary, such as in water treatment and aquaculture. Each type of pump has unique characteristics that make it suitable for specific tasks, underscoring the importance of understanding their functions for effective hydraulic system design and operation.

Understanding the Essential Functions of Hydraulic Pressure Pumps

This chart illustrates the efficiency percentages of various types of hydraulic pressure pumps, including gear pumps, piston pumps, vane pumps, screw pumps, and diaphragm pumps, showcasing their comparative performance.

Understanding Hydraulic Pressure: How It Works in Pump Systems

Hydraulic pressure is a critical component in various industrial applications, driving systems that require power and efficiency. At the heart of these systems are hydraulic pressure pumps, which convert mechanical energy into hydraulic energy. This process involves the movement of fluid, creating pressure that can perform work, such as lifting, pushing, or controlling machinery. According to a report by the International Fluid Power Society, the demand for hydraulic pumps is projected to grow by 7% annually, highlighting their indispensable role in sectors like construction, manufacturing, and agriculture.

When considering the efficiency of hydraulic pressure systems, it is essential to understand the factors that influence hydraulic pressure. Flow rate, viscosity, and temperature are significant elements that can alter performance. For instance, a decrease in fluid temperature can increase viscosity, affecting the flow rate and overall efficiency.

Tip: Regular maintenance of hydraulic systems can prevent changes in fluid properties and ensure optimal performance. Monitoring fluid temperature and viscosity can help identify potential issues before they impact the operation. Additionally, consider using high-quality hydraulic fluids that can withstand varying operational conditions for improved reliability and efficiency.

Common Applications of Hydraulic Pressure Pumps in Various Industries

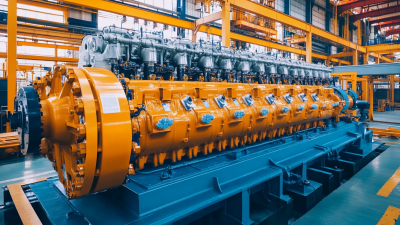

Hydraulic pressure pumps play a crucial role in numerous industries, providing the force needed to perform a variety of tasks efficiently. In construction, for instance, these pumps are essential for operating heavy machinery such as excavators and cranes, allowing for the seamless lifting and manipulation of large materials. The ability to generate immense pressure makes hydraulic systems ideal for tasks requiring precision and strength, ensuring safety and efficiency on the job site.

In the manufacturing sector, hydraulic pressure pumps are integral to metalworking and assembly lines. They power machines that press, cut, and mold materials, enhancing production speed while maintaining product quality. Additionally, the automotive industry relies on hydraulic systems for various processes, including the operation of braking systems and assembly of vehicle components. Whether it’s in agriculture, mining, or aerospace, hydraulic pressure pumps are indispensable tools that facilitate complex operations across diverse fields, showcasing their versatility and importance in today's industrial landscape.

Maintenance Tips for Optimizing Hydraulic Pressure Pump Performance

Hydraulic pressure pumps play a critical role in various industrial applications, but their efficiency heavily depends on regular maintenance. According to a report by the International Journal of Hydraulic Engineering, around 30% of hydraulic system failures can be traced back to inadequate maintenance practices. To optimize performance, it is essential to regularly inspect hydraulic fluid levels and ensure that they are clean, as contaminated fluids can significantly reduce pump efficiency and lifespan.

Another vital aspect of maintaining hydraulic pressure pumps is the monitoring of operating temperatures. The Society of Automotive Engineers (SAE) recommends keeping the fluid temperature within optimal ranges, typically between 30°C to 70°C (86°F to 158°F), to prevent thermal degradation of both the fluid and pump components. Regularly checking connection integrity and tightening any loose bolts or fittings can prevent leaks and minimize the risk of pressure loss. Implementing a proactive maintenance schedule not only enhances the pump's performance but also contributes to overall system reliability and efficiency, leading to reduced downtime and operational costs.