7 Reasons the Best Hydraulic Pump Motors Are Essential for Your Business Success

In the competitive landscape of modern industry, the efficiency and reliability of your machinery can make or break your business success. One of the critical components that plays a significant role in this regard is Hydraulic Pump Motors. These motors are the backbone of hydraulic systems, providing the necessary power to drive various applications ranging from manufacturing to construction. Understanding the detailed technical parameters and specifications of Hydraulic Pump Motors is essential for any business looking to enhance operational performance and productivity.

In this blog, we will explore seven compelling reasons why investing in top-quality hydraulic pump motors is not just beneficial, but essential for your business's growth and longevity. Prepare to delve into the intricate features and advantages that these motors offer, equipping you with the knowledge needed to make informed decisions for your operations.

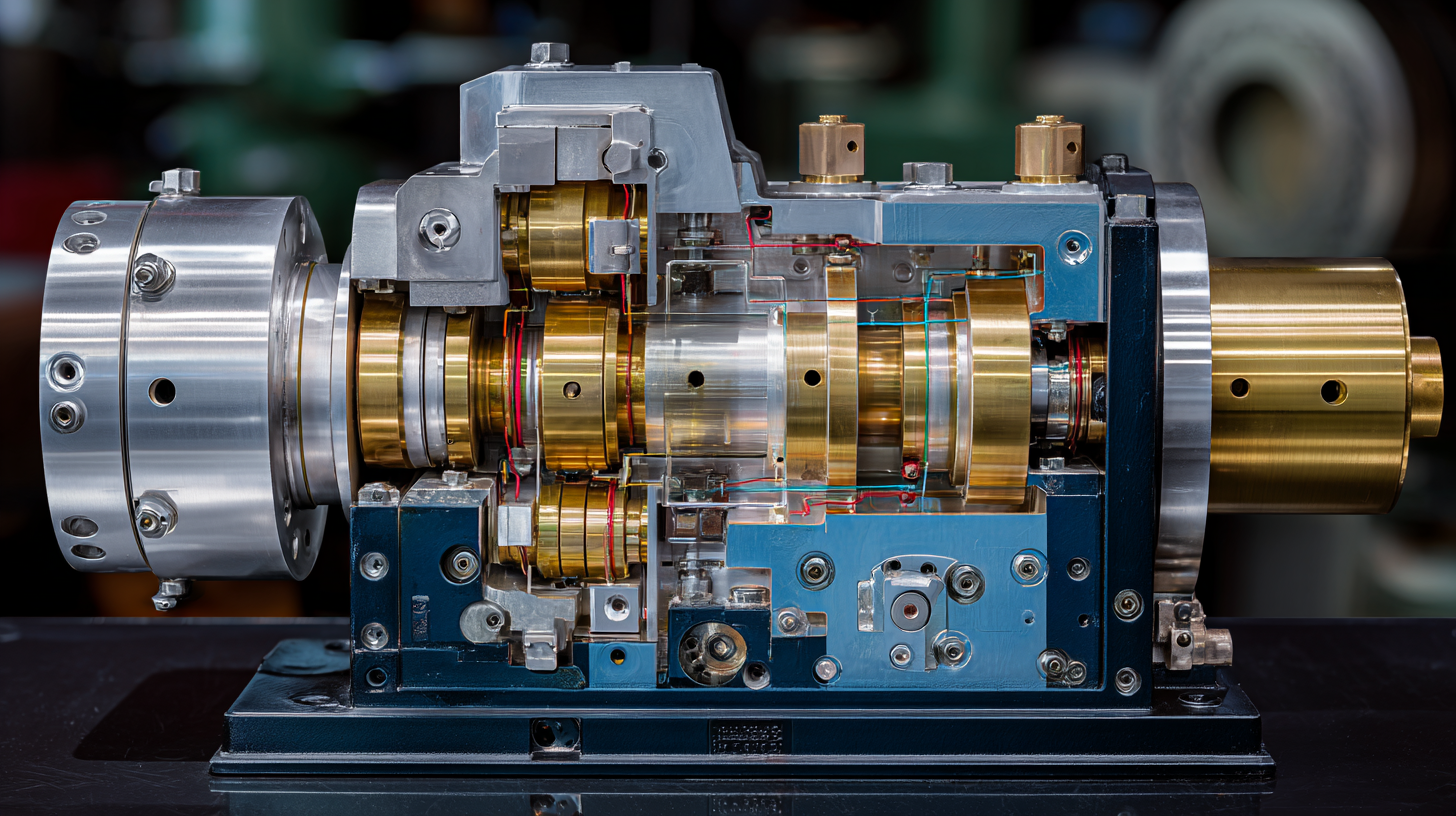

Key Features of High-Performance Hydraulic Pump Motors You Should Know

Hydraulic pump motors are integral to enhancing operational efficiency across various industries. Among the key features of high-performance hydraulic pump motors are their torque density and compact design. Recently, breakthroughs in axial flux motors have showcased exceptional torque density of 240 NM/KG and a maximum torque output of 580 NM. Such performance characteristics enable these motors to effectively meet high-demand applications, thus directly contributing to a company’s success in competitive markets.

Another critical feature of premium hydraulic pump motors is their rapid dynamic response. Innovations in motor technology, like those observed in advanced robotics, emphasize the necessity for agility and reliability. For instance, high-performance modules have been designed to ensure that even under varying loads, the motors maintain optimal performance. These advancements not only elevate the machines' efficiency but also pave the way for new applications in automation and robotics, making them indispensable tools for businesses aiming to stay ahead in their industries.

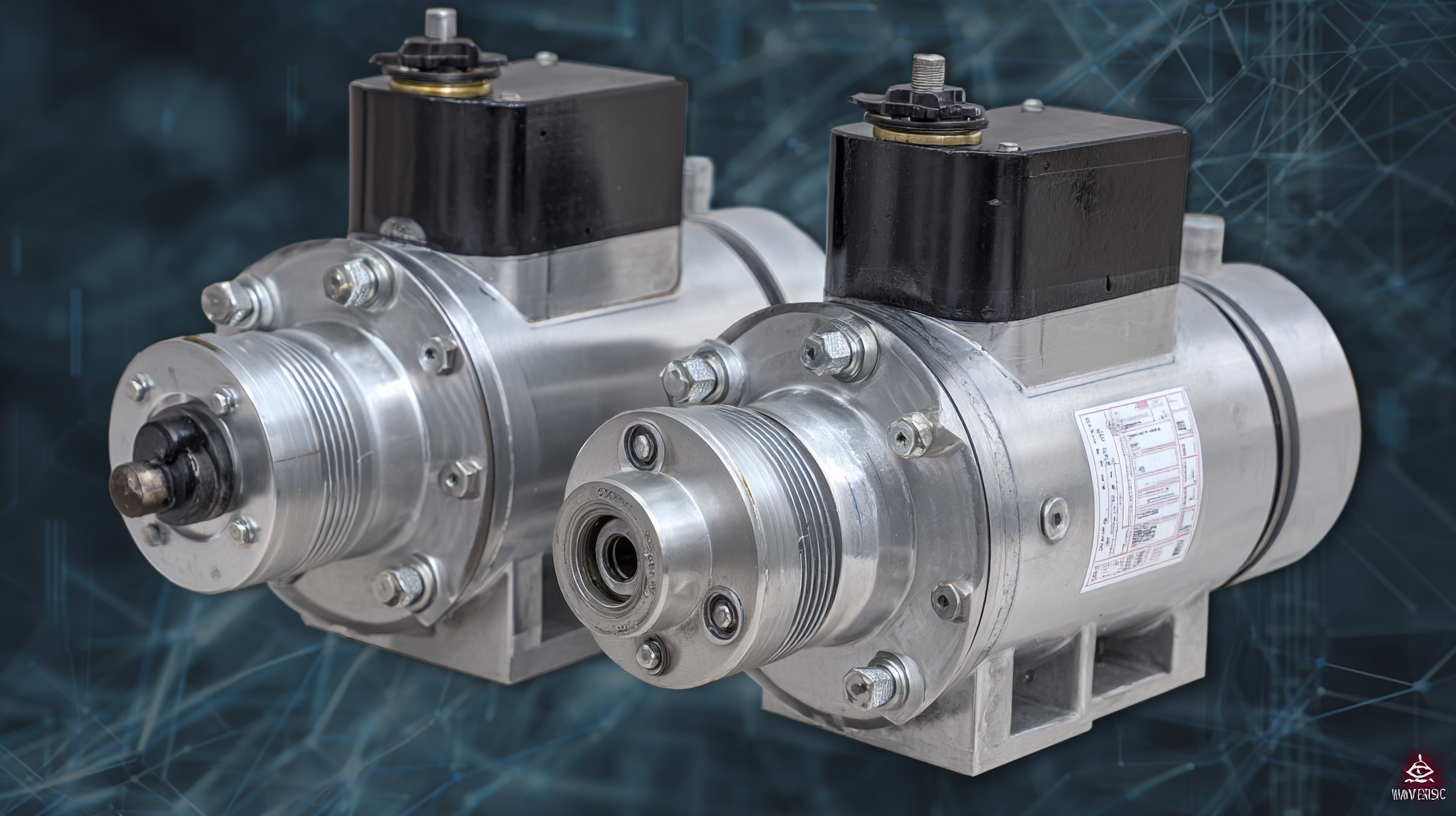

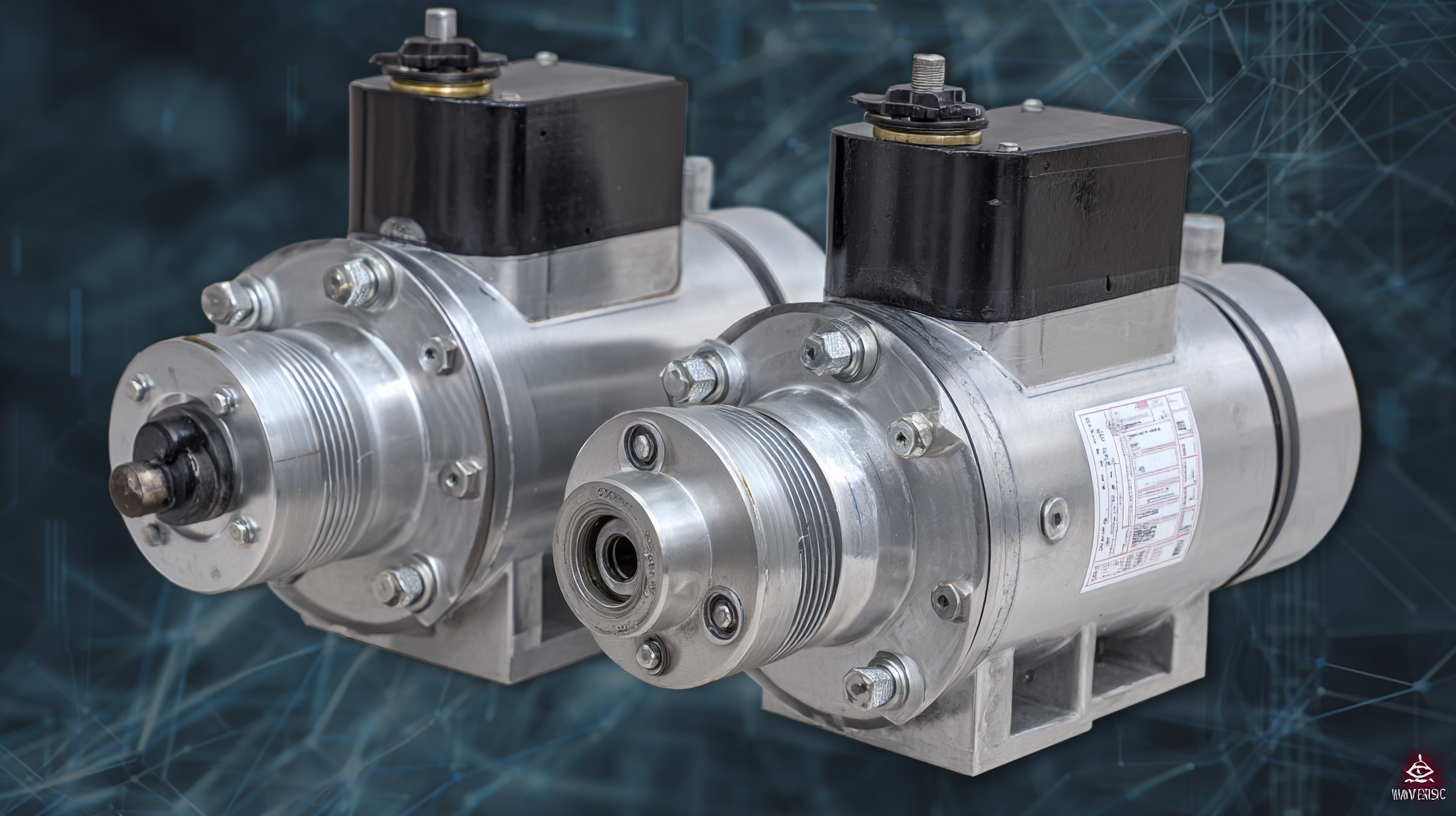

Different Types of Hydraulic Pump Motors and Their Unique Applications

Hydraulic pump motors are integral to various industrial applications, and understanding the different types available can significantly enhance business operations. Among the most common types are gear, vane, and piston pumps, each tailored for specific uses. Gear pumps are known for their reliability in transferring fluids at a constant flow, making them ideal for applications like material handling and lubrication systems. In contrast, vane pumps offer flexibility in flow adjustments and are often utilized in construction machinery where variable speeds are necessary. Piston pumps are preferred in high-pressure applications, such as in automotive and aerospace industries, where efficiency and precision are crucial.

As the global industrial hydraulic equipment market continues to grow—projected to be worth USD 52.6 billion by 2033—businesses must adapt to evolving demands. This includes the integration of advanced hydraulic systems designed to meet the requirements of electrification, highlighting the necessity for efficiency and modularity. The introduction of high-performance hydraulic motors can streamline operations, reducing energy consumption while increasing productivity. Factors such as the rise in global trade further emphasize the importance of investing in the right hydraulic technology to maintain competitive advantage in an increasingly challenging market.

7 Reasons the Best Hydraulic Pump Motors Are Essential for Your Business Success

This chart illustrates the importance of different types of hydraulic pump motors and their unique applications in various industries.

Understanding the Importance of Compatibility in Pump Motor Selection

When selecting hydraulic pump motors for your business, compatibility is paramount. A comprehensive study by the Hydraulic Institute indicates that improper pump motor selection can lead to a staggering 30% increase in operational costs due to inefficiencies and maintenance issues. Ensuring that your pump motors align perfectly with the hydraulic systems they're integrated into not only enhances performance but can also significantly extend equipment lifespan.

Furthermore, reports suggest that businesses prioritizing compatibility during their pump motor selection processes can boost productivity by up to 25%. This is largely due to reduced downtime from failures and better energy consumption metrics. For instance, using a motor that is compatible with variable speed drives can enhance efficiency by approximately 15%.

Therefore, investing time in understanding the nuances of compatibility can yield substantial long-term savings and operational reliability for organizations in the industrial sector.

How to Evaluate the Efficiency and Durability of Hydraulic Pump Motors

When evaluating the efficiency and durability of hydraulic pump motors, it’s essential to consider several key factors. First, assess the motor’s performance ratings, including flow rate and pressure capabilities. High efficiency in these areas can significantly reduce energy consumption and operational costs. Look for motors that feature advanced design elements like high-efficiency impellers and optimized fluid dynamics, as these can enhance overall performance. Additionally, consider the type of motor—whether it’s an AC, DC, or variable frequency drive—as each may offer different advantages depending on your specific application.

Durability is another critical factor in selecting hydraulic pump motors. Investigate the materials used in the construction of the motor to ensure they can withstand harsh operating conditions. Motors with protective coatings or those made from corrosion-resistant materials tend to have longer lifespans. Regular maintenance and monitoring are also vital; look for motors that come equipped with diagnostic tools to help track performance over time. Ultimately, choosing a hydraulic pump motor that excels in efficiency and durability will not only boost your operational success but also minimize downtime and maintenance costs, contributing to the overall profitability of your business.

Common Maintenance Tips to Ensure Long-Term Performance of Your Hydraulic Systems

Maintaining hydraulic systems is crucial for ensuring their long-term performance and preventing costly downtimes. One of the most effective maintenance tips is to regularly check the hydraulic fluid levels and quality. Contaminated or low fluid can lead to inefficient operation and increased wear on the pump motors. Implementing a routine schedule for fluid replacement and testing can help identify issues before they escalate, ultimately extending the life of your equipment.

Another important aspect of maintenance is to conduct regular inspections of the hydraulic pump motors and associated components. This includes checking for leaks, wear on seals, and the condition of hoses and fittings. Simple visual checks can catch potential problems early, allowing for timely repairs. Furthermore, ensure that the motors are properly lubricated according to the manufacturer’s specifications, which can significantly enhance their efficiency and reliability. By prioritizing these common maintenance tasks, businesses can safeguard their hydraulic systems against unexpected failures, ensuring that their operations run smoothly and successfully.