5 Essential Tips for Choosing the Right Truck Hydraulic Pump

When it comes to enhancing the performance and efficiency of your vehicle, choosing the right Truck Hydraulic Pump is crucial. A quality hydraulic pump is not just an accessory; it's the heart of your truck's hydraulic system, influencing everything from lifting heavy loads to powering various attachments. However, with the myriad of options available on the market, selecting the perfect pump can be daunting. In this blog, we will explore five essential tips to help you make an informed decision. We will delve into critical factors such as compatibility, size, pressure ratings, and efficiency that will lead you to the best hydraulic pump for your truck. Whether you're a fleet manager or an off-road enthusiast, understanding these key aspects will ensure your truck's hydraulic system operates seamlessly, ultimately boosting your productivity and reducing downtime. Let's dive into the reasons why choosing the right Truck Hydraulic Pump matters and how it can significantly impact your operations.

Understanding Different Types of Truck Hydraulic Pumps: A Comprehensive Guide

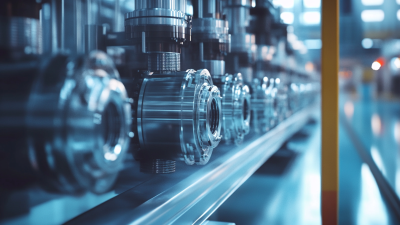

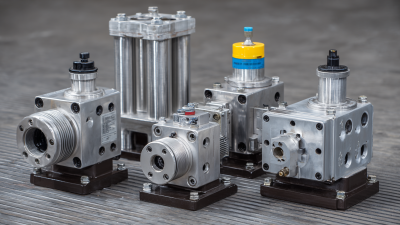

When selecting the right truck hydraulic pump, it's crucial to understand the different types available in the market. Hydraulic pumps are generally classified into gear pumps, vane pumps, and piston pumps, each with its unique advantages and suited applications.

Gear pumps, for instance, are known for their durability and efficiency in low-pressure applications, making them ideal for standard hydraulic systems in trucks. A recent market analysis indicates that gear pumps dominate the segment, accounting for approximately 45% of the hydraulic pump market due to their simplicity and reliability.

On the other hand, vane pumps offer a greater flow range and are preferred in medium-pressure applications. According to the Hydraulic Institute’s report, these pumps are gaining traction in industries requiring precise flow control, showing a compound annual growth rate (CAGR) of 5.5% over the next five years.

Finally, piston pumps, while more expensive, are unparalleled in high-pressure systems and are often used in heavy-duty vehicles. Understanding these distinctions can enhance equipment operation efficiency and longevity, ultimately contributing to the better performance of your trucking operations.

Key Factors to Consider When Evaluating Alternatives to Truck Hydraulic Pumps

When evaluating alternatives to truck hydraulic pumps, it's essential to consider several key factors that can significantly impact performance and efficiency.

First, the system's flow rate is critical; ensure that the alternative pump meets the specific demands of your application. Pumps that can't provide the necessary flow may lead to inadequate power and response times, resulting in subpar operation and potential project delays.

Another crucial factor is the pump's compatibility with your existing system. Different hydraulic fluids and system pressures may require specialized pumps to ensure seamless integration. This aspect is often overlooked but can lead to severe inefficiencies or equipment damage if not properly addressed. Additionally, consider the type of pump—gear, vane, or piston—since each design offers unique benefits and drawbacks that may suit specific tasks better than others. Always prioritize reliability and durability, as these characteristics will determine the long-term viability of your pump and its overall contribution to your operational needs.

Advantages and Disadvantages of Popular Hydraulic Pump Alternatives

When selecting a hydraulic pump for your truck, it's essential to weigh the advantages and disadvantages of popular alternatives. Gear pumps, for example, are favored for their simplicity and high efficiency. They excel in generating consistent flow rates, making them suitable for various applications. However, their performance can be affected by temperature fluctuations and system pressure variations, which might lead to increased wear over time.

When selecting a hydraulic pump for your truck, it's essential to weigh the advantages and disadvantages of popular alternatives. Gear pumps, for example, are favored for their simplicity and high efficiency. They excel in generating consistent flow rates, making them suitable for various applications. However, their performance can be affected by temperature fluctuations and system pressure variations, which might lead to increased wear over time.

Another common choice is the piston pump, known for its high pressure and versatility. They can deliver significantly higher flow rates, making them ideal for heavy-duty applications. Nonetheless, they are often more complex and expensive than gear pumps, requiring more maintenance. Additionally, the installation process can be more challenging, especially in limited space situations. Understanding these trade-offs ensures that you make a more informed decision that fits your specific operational needs when selecting a hydraulic pump for your truck.

Cost-Effectiveness Analysis: Traditional vs. Alternative Hydraulic Pump Solutions

When considering a hydraulic pump for your truck, a cost-effectiveness analysis of traditional versus alternative solutions is paramount. Traditional hydraulic pumps have long been the standard choice for many operators. They are often more familiar and come with a proven track record of performance. However, their initial purchase price and maintenance costs can add up over time, particularly for businesses operating on tight budgets.

On the other hand, alternative hydraulic pump solutions, such as electric or hybrid systems, present a compelling case for cost-effectiveness. While the upfront investment might be higher, these pumps can lead to significant savings in fuel consumption and lower maintenance requirements in the long run. Moreover, advancements in technology have made alternative solutions more efficient and reliable, reducing downtime and promoting consistent performance. This shift not only supports operational budgets but also aligns with growing environmental regulations by minimizing carbon footprints. Evaluating both options carefully can help businesses make informed decisions that balance initial costs with long-term savings and sustainability.

Maintenance and Durability: Choosing the Best Long-Term Option for Your Needs

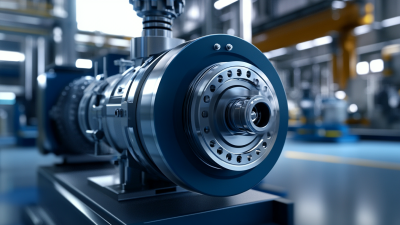

When selecting a truck hydraulic pump, maintenance and durability should be paramount considerations. According to a report by the Hydraulic Manufacturers Association, approximately 30% of hydraulic system failures can be attributed to inadequate maintenance. Regular maintenance practices, such as fluid checks and filter replacements, can significantly extend the lifespan of your pump and enhance its efficiency. Additionally, investing in a pump with durable materials, such as high-strength alloys, can resist wear and tear and reduce the risk of unexpected breakdowns.

Furthermore, it's essential to consider the long-term operational costs associated with your hydraulic pump choice. A study published by the National Fluid Power Association indicates that choosing a pump designed for durability can result in up to 20% lower operational costs over its lifespan. This is due to reduced downtime, lower maintenance expenses, and improved energy efficiency. Brands that offer warranties and extensive service plans typically indicate a confidence in their product’s durability, making them worthy of consideration when prioritizing long-term investment in your hydraulic system.

When selecting a hydraulic pump for your truck, it's essential to weigh the advantages and disadvantages of popular alternatives. Gear pumps, for example, are favored for their simplicity and high efficiency. They excel in generating consistent flow rates, making them suitable for various applications. However, their performance can be affected by temperature fluctuations and system pressure variations, which might lead to increased wear over time.

When selecting a hydraulic pump for your truck, it's essential to weigh the advantages and disadvantages of popular alternatives. Gear pumps, for example, are favored for their simplicity and high efficiency. They excel in generating consistent flow rates, making them suitable for various applications. However, their performance can be affected by temperature fluctuations and system pressure variations, which might lead to increased wear over time.