The Future of Hydraulic Pump Innovations: Trends Shaping Tomorrow's Industry

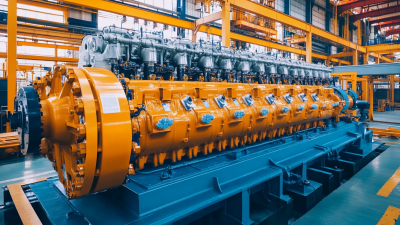

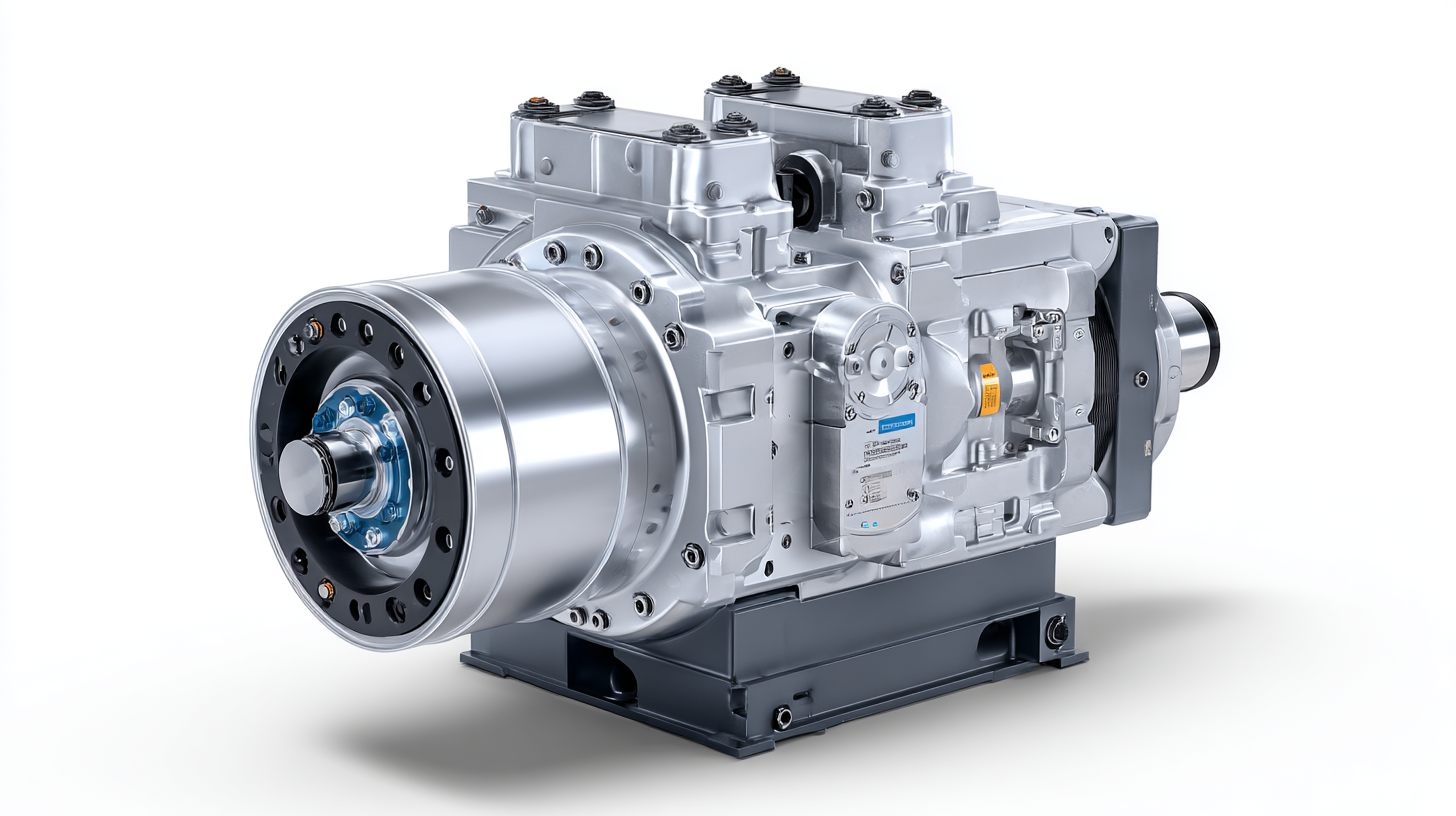

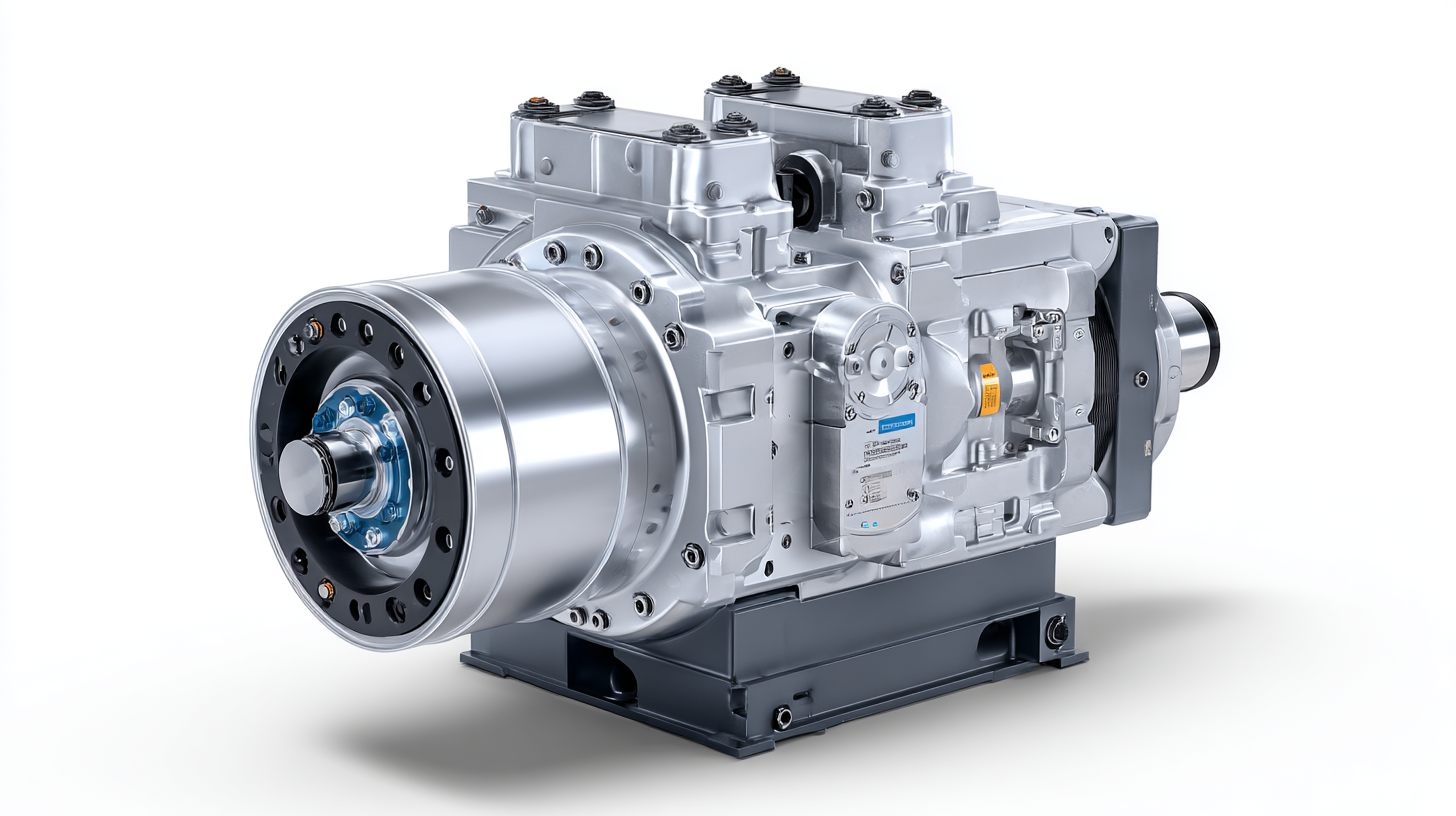

As the demand for efficiency and sustainability continues to reshape various industries, innovations in hydraulic pump technology are becoming increasingly essential. A hydraulic pump, which plays a crucial role in converting mechanical energy into hydraulic energy, is at the forefront of this transformation. With the rise of automation and the push toward greener solutions, manufacturers are exploring advanced materials, electronic controls, and smart technologies to enhance their pumps' performance and reliability. This blog will delve into the key trends and technological advancements that are shaping the future of hydraulic pumps, examining how these innovations not only improve operational efficiency but also contribute to a more sustainable industrial landscape. By understanding these trends, companies can better prepare for the evolving market and leverage new opportunities for growth in the hydraulic pump sector.

As the demand for efficiency and sustainability continues to reshape various industries, innovations in hydraulic pump technology are becoming increasingly essential. A hydraulic pump, which plays a crucial role in converting mechanical energy into hydraulic energy, is at the forefront of this transformation. With the rise of automation and the push toward greener solutions, manufacturers are exploring advanced materials, electronic controls, and smart technologies to enhance their pumps' performance and reliability. This blog will delve into the key trends and technological advancements that are shaping the future of hydraulic pumps, examining how these innovations not only improve operational efficiency but also contribute to a more sustainable industrial landscape. By understanding these trends, companies can better prepare for the evolving market and leverage new opportunities for growth in the hydraulic pump sector.

Emerging Technologies Revolutionizing Hydraulic Pump Design and Efficiency

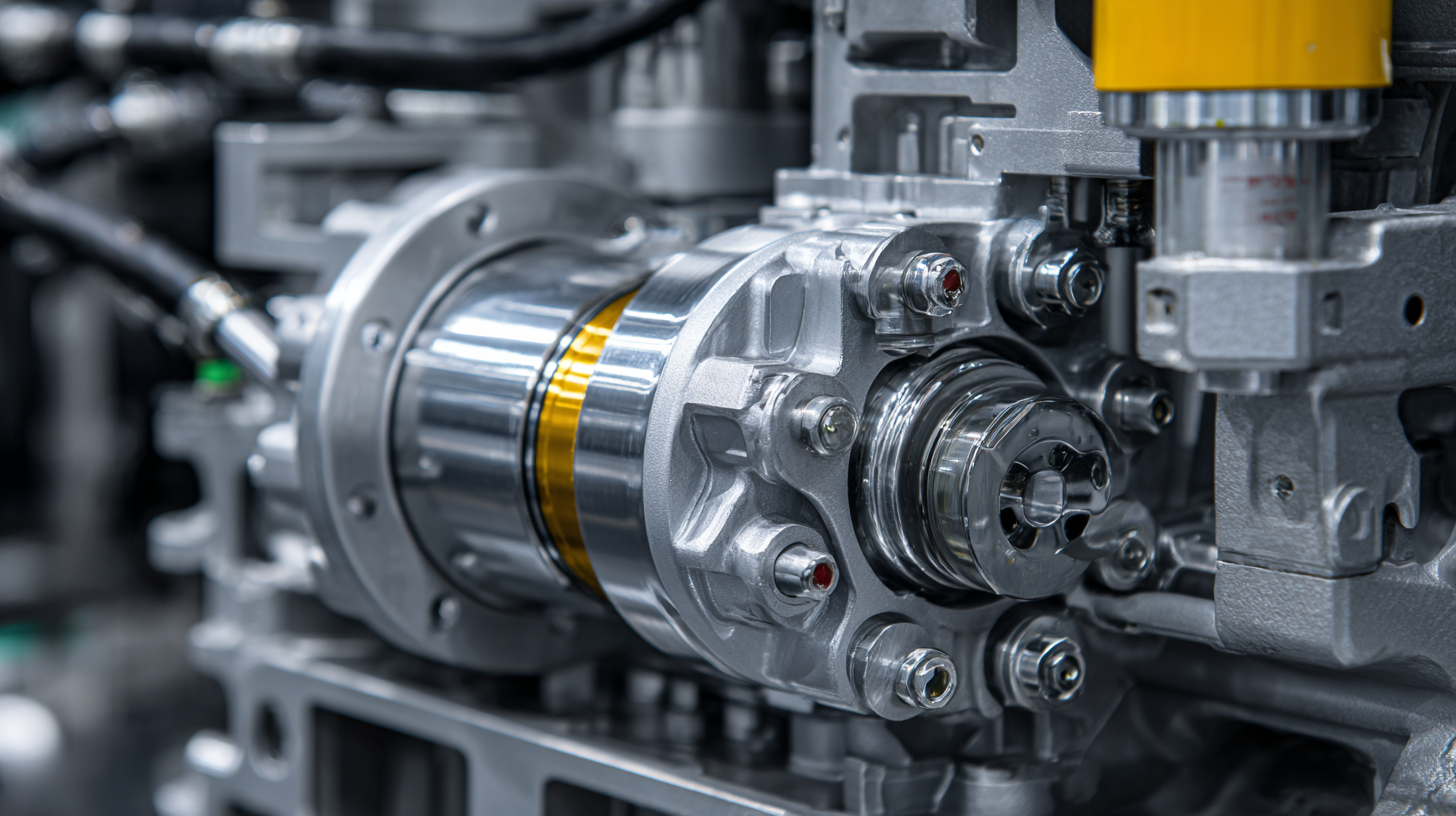

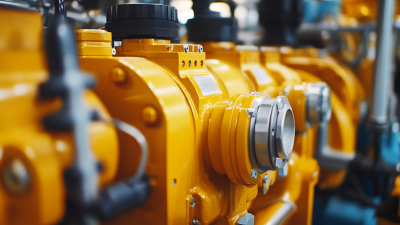

The hydraulic pump industry is experiencing a transformative phase driven by emerging technologies that are redefining design and efficiency. Innovations such as IoT integration, smart sensors, and advanced materials are taking center stage. IoT-enabled hydraulic pumps allow for real-time monitoring and predictive maintenance, significantly reducing downtime and operational costs. These smart pumps can send alerts about performance anomalies and maintenance needs, empowering companies to take proactive measures before failures occur.

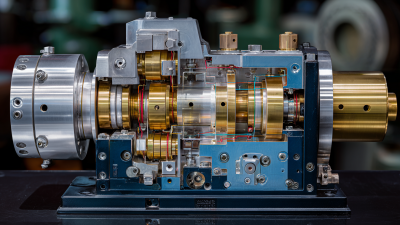

Moreover, advancements in materials science are leading to lighter, more durable components that enhance pump performance while minimizing energy consumption. For instance, composite materials are being utilized to construct hydraulic pumps that are not only resistant to wear and tear but also improve overall energy efficiency. Additionally, the rise of energy-efficient designs, such as variable displacement pumps, is enabling industries to utilize hydraulic systems that consume less power while providing the same output. As these technologies continue to evolve, they promise to revolutionize the hydraulic pump landscape, making it more sustainable and efficient for future applications.

The Future of Hydraulic Pump Innovations: Key Trends and Efficiency Improvements

The Role of IoT and Smart Sensors in Modern Hydraulic Systems

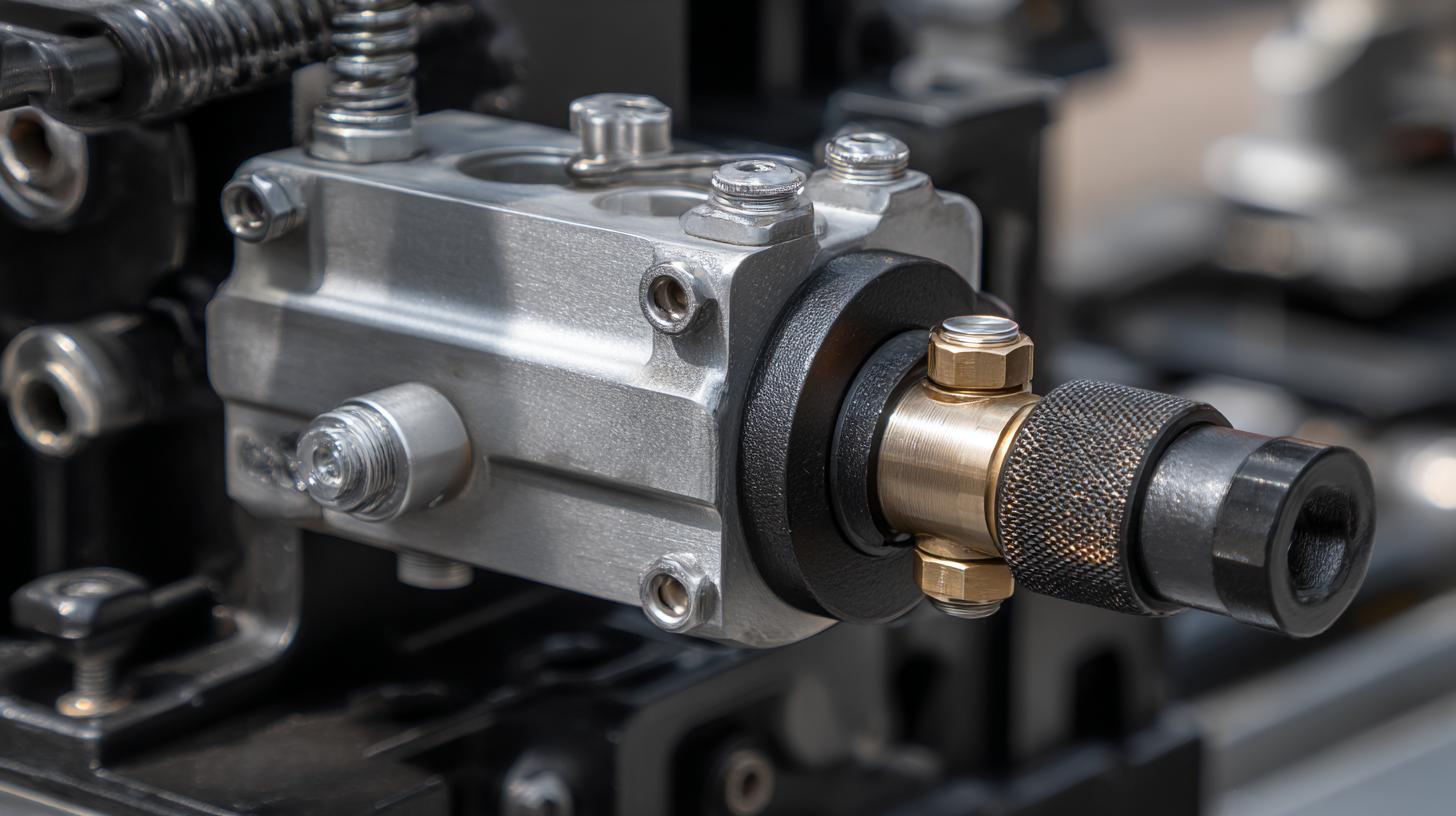

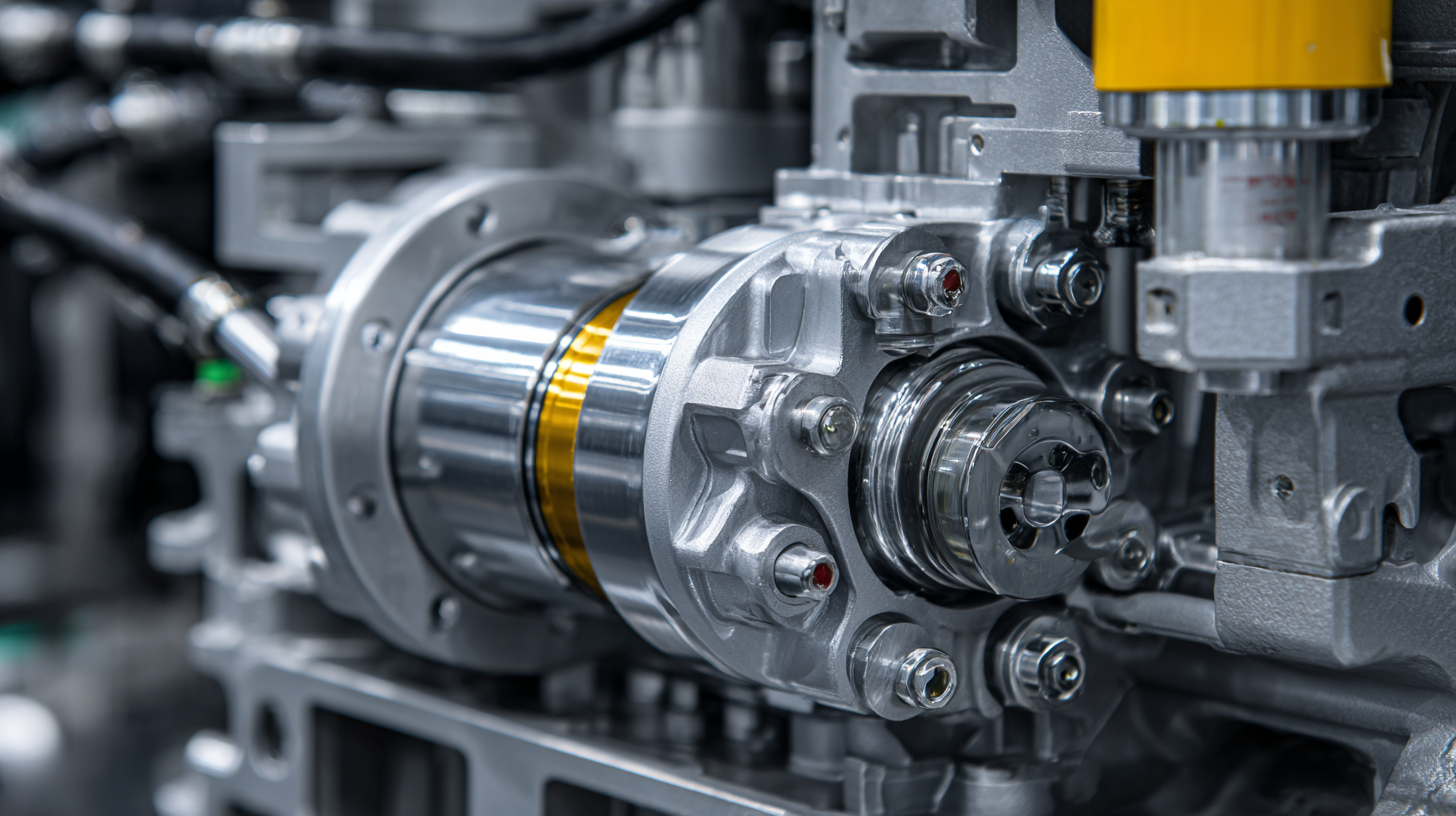

The integration of the Internet of Things (IoT) and smart sensors is revolutionizing modern hydraulic systems, fundamentally transforming how they operate and interact with their environments. By embedding smart sensors within hydraulic pumps and machinery, operators can continuously monitor performance metrics such as pressure, temperature, and flow rates in real-time. This data-driven approach enables predictive maintenance, reducing downtime and extending equipment longevity while ensuring optimal performance.

Furthermore, the IoT framework allows these hydraulic systems to be remotely controlled and monitored, providing users with unprecedented access and flexibility. Through cloud-based platforms, engineers can analyze large sets of data, enabling intelligent decision-making and instantaneous adjustments to system parameters. This tech-driven paradigm not only enhances operational efficiency but also paves the way for smarter, more sustainable hydraulic solutions tailored to the specific needs of industries ranging from manufacturing to construction. As innovations continue to emerge, the synergy between IoT technology and hydraulic systems promises to shape a more connected and responsive future.

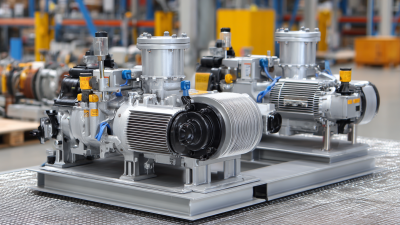

Sustainable Practices: Eco-Friendly Innovations in Hydraulic Pump Manufacturing

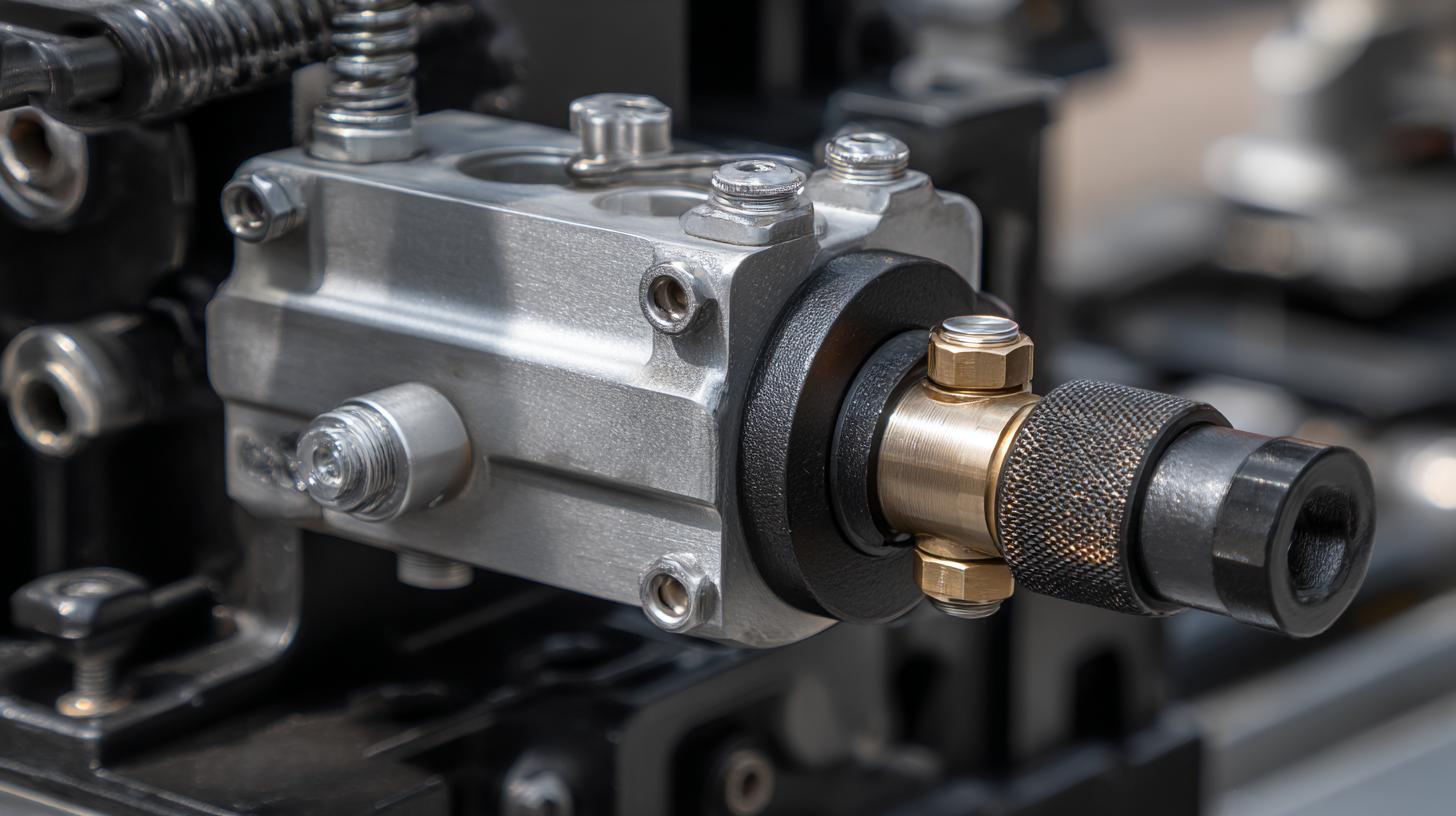

As the hydraulic pump industry evolves, sustainable practices are becoming a paramount focus in manufacturing processes. Innovations aimed at reducing the environmental impact of hydraulic pumps not only foster compliance with regulations but also appeal to eco-conscious consumers.

Manufacturers are increasingly investing in research and development to create pumps that utilize biodegradable fluids, thereby minimizing the risk of environmental contamination. Moreover, the implementation of energy-efficient designs is gaining traction, which significantly reduces energy consumption and greenhouse gas emissions throughout the product lifecycle.

Another noteworthy trend is the adoption of recyclable materials in the production of hydraulic pumps. By incorporating materials that can be reused at the end of their life cycle, manufacturers are not only addressing waste management issues but also enhancing their corporate social responsibility. This shift towards eco-friendly innovations is not just about meeting industry standards; it signals a broader commitment to sustainability, which resonates with an increasingly environmentally aware market. As these trends shape the future of hydraulic pump manufacturing, they pave the way for a greener, more sustainable industry that aligns economic growth with ecological stewardship.

Predictive Maintenance: Enhancing Reliability with Advanced Data Analytics

The future of hydraulic pump innovations is increasingly intertwined with the adoption of predictive maintenance practices, driven by advanced data analytics. According to a report by MarketsandMarkets, the predictive maintenance market is projected to grow from $3.1 billion in 2020 to $12.3 billion by 2026, reflecting a compound annual growth rate (CAGR) of 25.5%. This substantial growth highlights the industry's shift towards more proactive maintenance strategies that not only enhance the reliability of hydraulic systems but also reduce operational costs.

Advanced data analytics plays a crucial role in predictive maintenance by enabling real-time monitoring and analysis of hydraulic pump performance. By leveraging Internet of Things (IoT) technologies, operators can collect vast amounts of data on pump metrics such as pressure, temperature, and vibration levels. A study by Deloitte suggests that businesses implementing predictive analytics can reduce maintenance costs by 10-20%, while also decreasing unexpected breakdowns by up to 50%. As hydraulic systems become increasingly complex, integrating data analytics will be key to ensuring optimal performance and extending equipment lifecycles, ultimately shaping the future landscape of the industry.

The Future of Hydraulic Pump Innovations: Trends Shaping Tomorrow's Industry

| Innovation Area |

Technology |

Benefits |

Implementation Challenges |

Future Outlook |

| Smart Sensors |

IoT Integration |

Real-time performance monitoring |

High initial costs |

Increased adoption in industrial settings |

| Predictive Analytics |

Machine Learning Algorithms |

Enhanced reliability through data insights |

Data integration difficulties |

Lower maintenance costs predicted |

| Remote Monitoring |

Cloud Computing |

Access to system performance from anywhere |

Cybersecurity risks |

Expansion into more sectors expected |

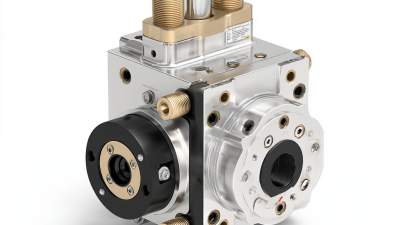

| Energy Efficiency |

Variable Displacement Technology |

Reduction in energy consumption |

Retrofitting older systems |

Rising demand in eco-friendly standards |

| Material Innovations |

Composite Materials |

Increased durability and reduced weight |

Higher material costs |

Growth in various industrial applications |

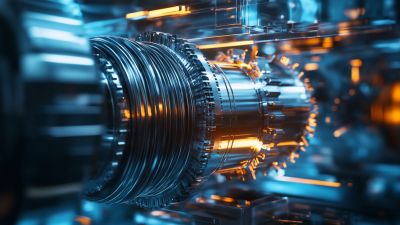

Future-Ready Hydraulics: Adapting to Industry 4.0 and Beyond

The rapid evolution of Industry 4.0 is driving transformative changes in hydraulic pump technology. As industries increasingly embrace digitalization, hydraulic systems must adapt to new demands for efficiency and automation. The integration of IoT (Internet of Things) into hydraulic pumps allows for real-time monitoring and predictive maintenance, ensuring systems run at optimal performance while minimizing downtime. This shift not only enhances productivity but also fosters a culture of proactive management in industrial settings.

Moreover, advancements in materials science and energy-efficient designs are shaping the future landscape of hydraulic pumps. Innovations such as smart sensors and adaptive control systems are emerging, enabling pumps to adjust performance dynamically based on operational conditions. This results in reduced energy consumption and better responsiveness to varying load requirements. As manufacturers prioritize sustainability and efficiency, the hydraulic pump industry is poised to play a crucial role in the broader narrative of eco-friendly industrial practices, paving the way for future-ready solutions that align with contemporary environmental standards.

As the demand for efficiency and sustainability continues to reshape various industries, innovations in hydraulic pump technology are becoming increasingly essential. A hydraulic pump, which plays a crucial role in converting

As the demand for efficiency and sustainability continues to reshape various industries, innovations in hydraulic pump technology are becoming increasingly essential. A hydraulic pump, which plays a crucial role in converting