The Future of Best Main Hydraulic Pump Technology Advancements

As we look towards 2025, the landscape of hydraulic technology is poised for significant transformation, particularly in the realm of Main Hydraulic Pumps. According to a recent report by Research and Markets, the global hydraulic pumps market is projected to reach $19.3 billion by 2025, with a compound annual growth rate (CAGR) of 6.3% from 2020. This surge in demand underscores the need for advancements in pump efficiency, durability, and adaptability to meet the ever-evolving needs of various industries, including construction, agriculture, and manufacturing. Emerging trends point toward the integration of IoT and AI technologies into hydraulic systems, which promise to enhance the performance and reliability of Main Hydraulic Pumps, ultimately leading to greater operational efficiency and sustainability in hydraulic applications. As we explore these developments, it becomes clear that the future of Main Hydraulic Pump technology is not just about enhancing performance, but also about creating smarter, more connected systems that align with the demands of an increasingly digital world.

The Evolution of Hydraulic Pump Technology: A Historical Perspective

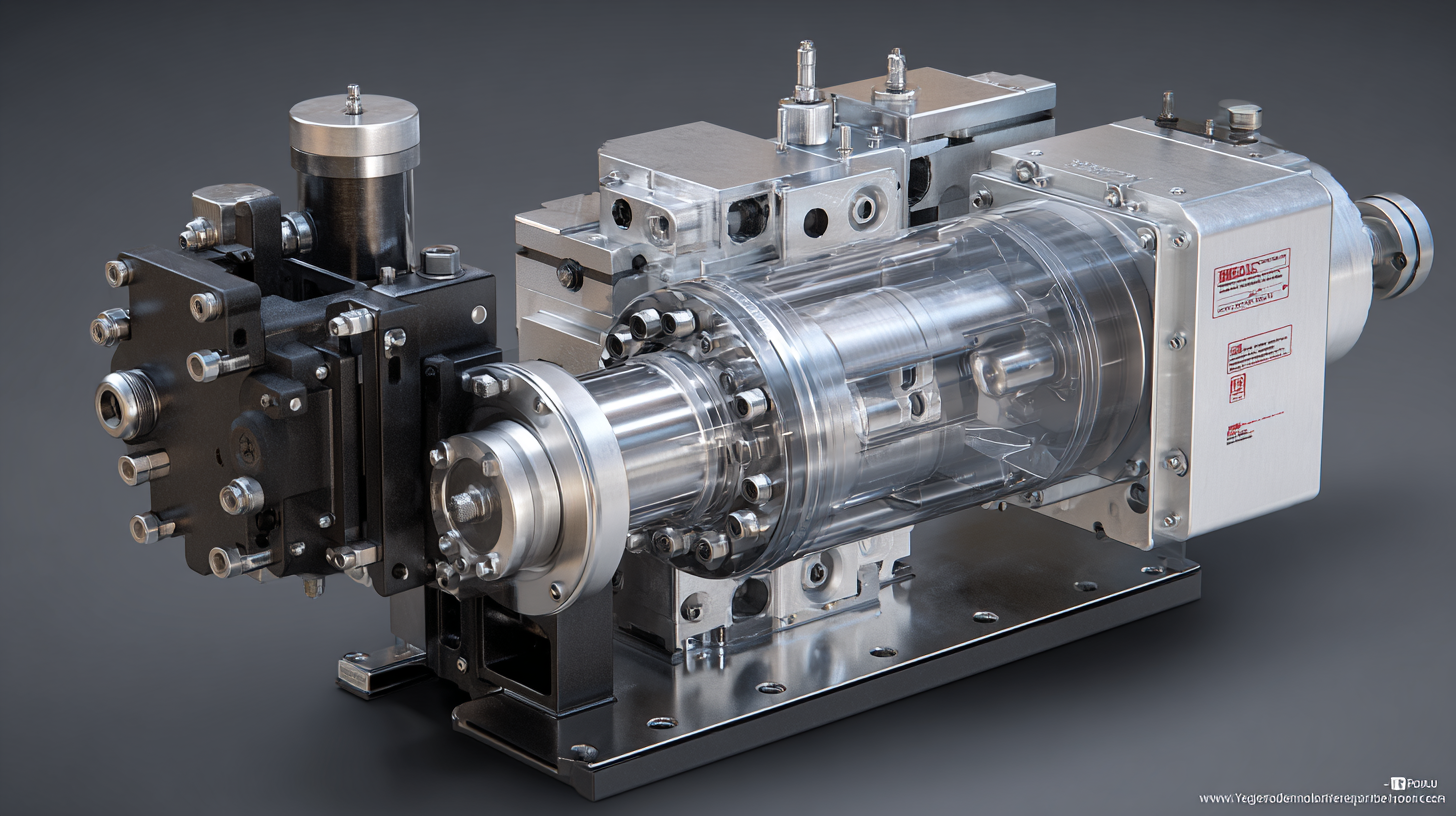

The history of hydraulic pump technology is a fascinating journey that showcases human ingenuity and the quest for efficiency. Initially, hydraulic systems relied on simple mechanical principles, utilizing gravity and manual force to generate pressure. Over the decades, advancements in materials and engineering techniques revolutionized the design and performance of hydraulic pumps. The introduction of different pumping mechanisms, such as gear, vane, and piston pumps, allowed for greater versatility and efficiency in various industrial applications.

As we moved into the modern era, technological breakthroughs significantly impacted hydraulic pump capabilities. The integration of digital controls and smart sensors enhanced performance monitoring and optimization, paving the way for more responsive and automated systems. Furthermore, innovations in materials science have resulted in lighter, more durable components that can withstand higher pressures and temperatures, thus expanding the operational scope of hydraulic systems. These evolutionary steps highlight the importance of continuous development in hydraulic pump technology, ensuring that it meets the demands of an increasingly complex industrial landscape.

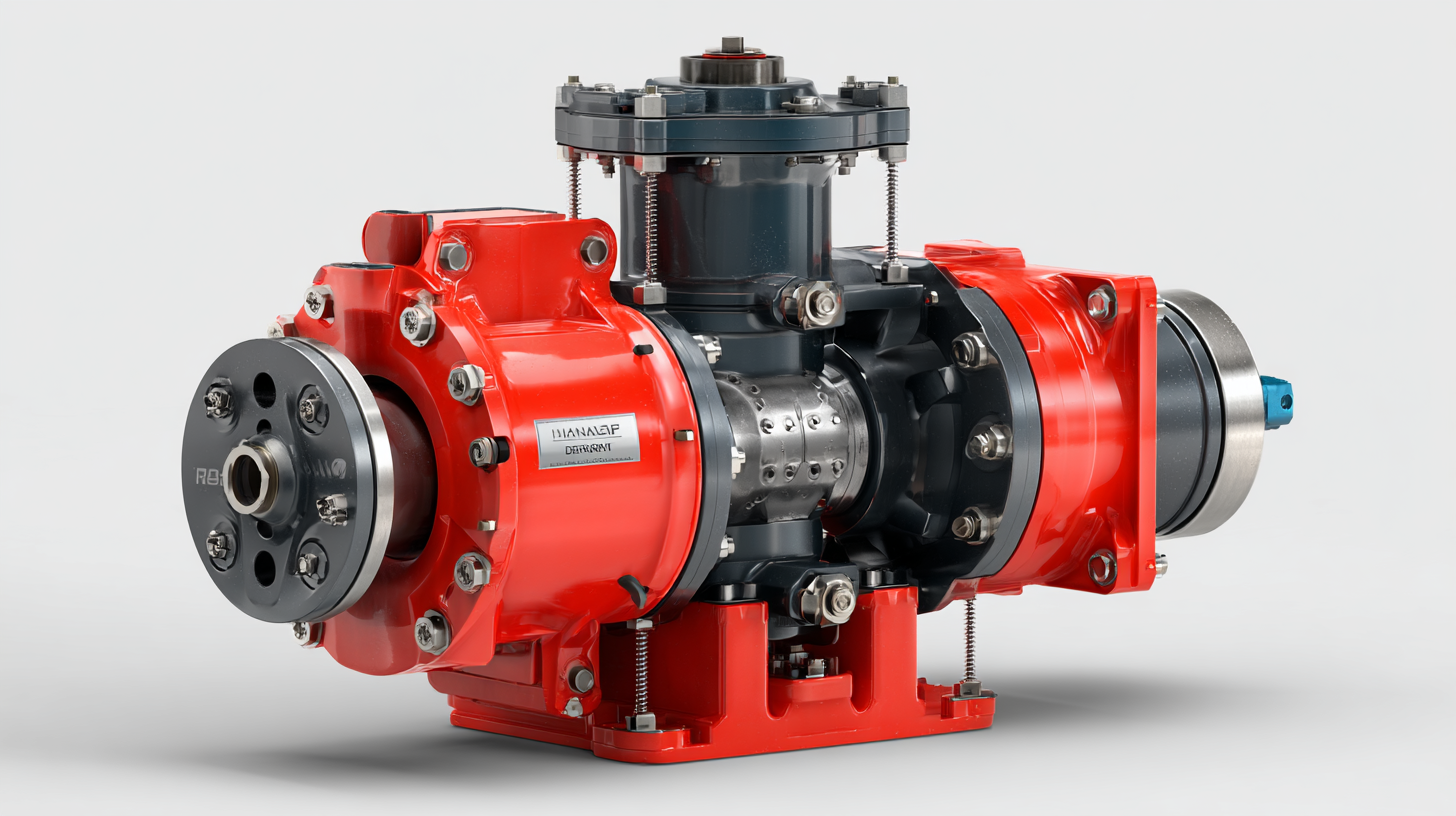

Key Innovations in Main Hydraulic Pumps: What to Expect in the Future

The evolution of main hydraulic pump technology is set to transform industries that rely on hydraulic systems. Key innovations are emerging in areas such as energy efficiency, digital integration, and materials engineering. One of the most significant advancements involves the development of variable displacement pumps, which provide increased efficiency by adapting the flow rate based on real-time demand. This precision not only reduces energy consumption but also enhances overall system responsiveness, leading to better performance in applications ranging from construction machinery to agricultural equipment.

Moreover, the integration of smart technology into hydraulic systems is on the rise. IoT-enabled hydraulic pumps can transmit data on performance and maintenance needs, allowing for proactive management and minimizing downtime. This connectivity opens the door to predictive maintenance, where potential issues can be identified and resolved before they lead to failures, significantly saving costs and resources. As manufacturers continue to focus on sustainability and efficiency, these innovations set the stage for a future where hydraulic systems are not only more powerful but also environmentally friendly.

China's Role in Global Hydraulic Pump Manufacturing: A Competitive Analysis

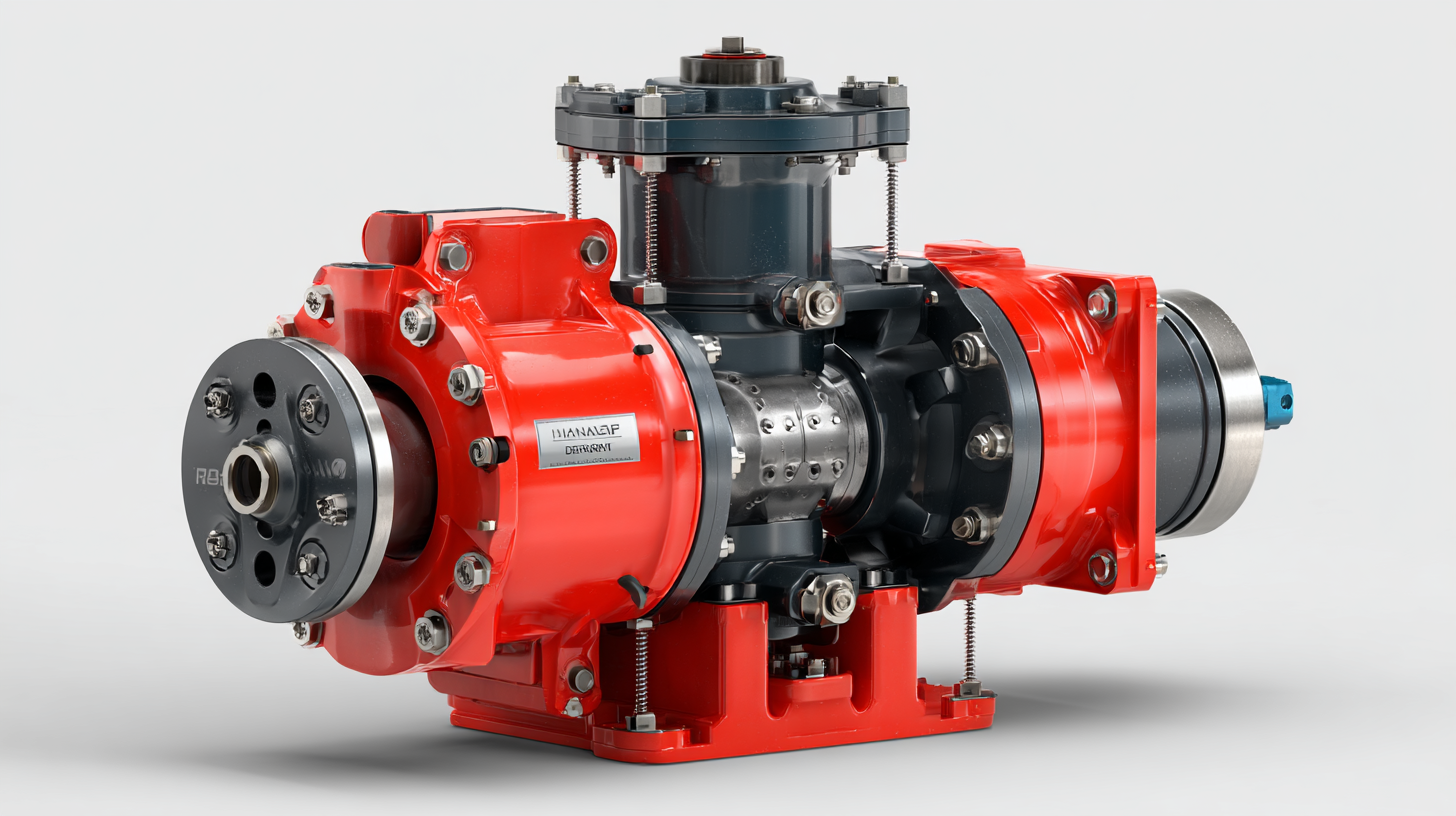

China has rapidly emerged as a dominant player in the global hydraulic pump manufacturing industry, driven by significant investments in technology and production capacity. With a robust supply chain and a skilled workforce, Chinese manufacturers are able to produce high-quality hydraulic pumps at competitive prices. This has enabled them to capture a substantial share of the global market, challenging established brands from Europe and North America. The integration of advanced manufacturing techniques, such as automation and precision engineering, has further reinforced China's position as a leader in hydraulic pump innovation.

In addition to cost advantages, China's focus on research and development has been pivotal in enhancing the performance and efficiency of hydraulic pumps. Chinese companies are increasingly investing in smart technologies, incorporating IoT and AI capabilities to create systems that offer real-time monitoring and predictive maintenance. This not only improves operational efficiency but also aligns with global sustainability goals by reducing energy consumption and carbon footprints. As China continues to innovate and expand its capabilities, its role in the hydraulic pump sector will likely further evolve, shaping the future landscape of hydraulic technology on a global scale.

Sustainability in Hydraulic Technology: Embracing Eco-friendly Practices

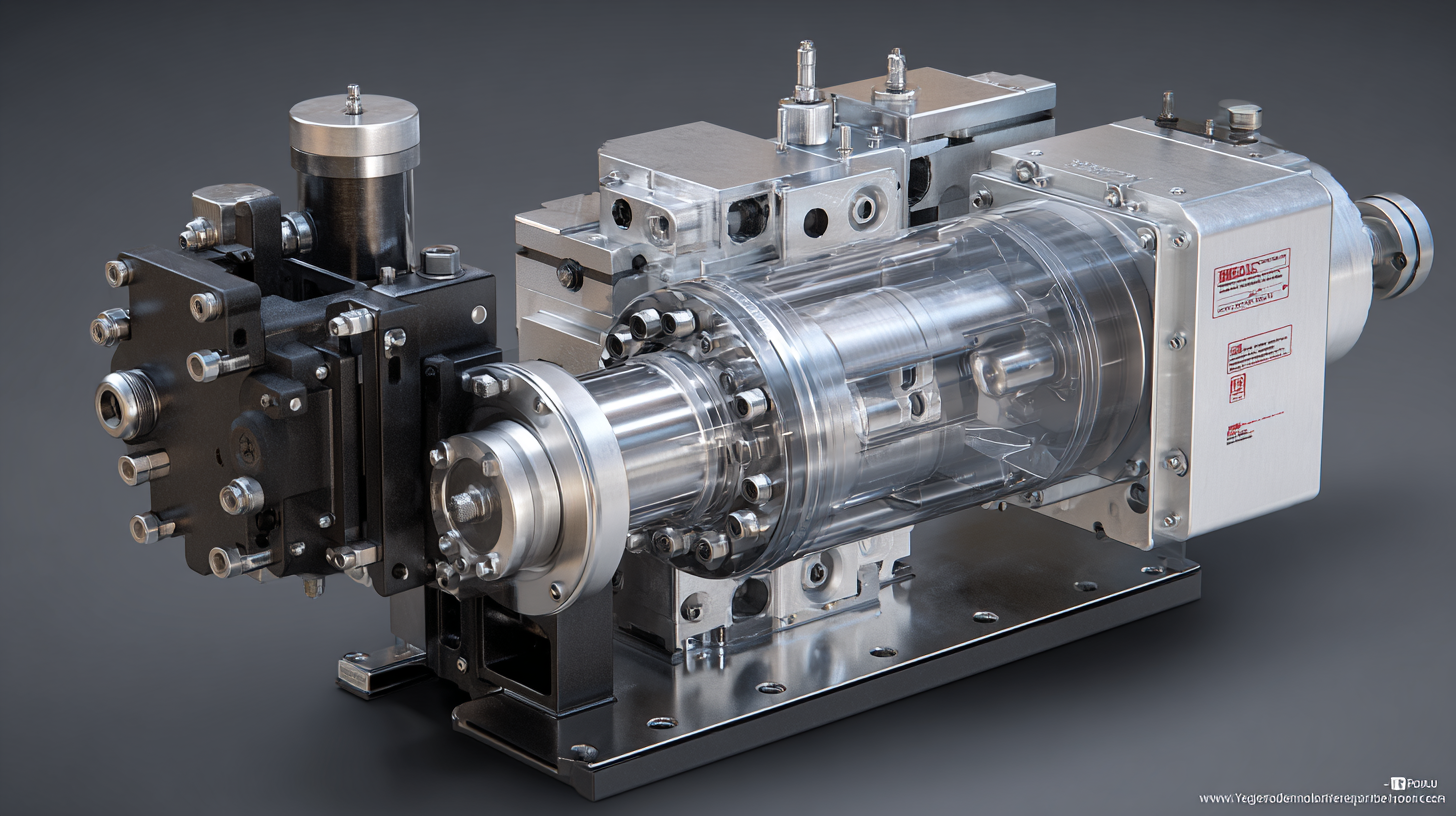

In recent years, the hydraulic industry has seen a significant shift towards sustainability, reflecting growing environmental concerns and the necessity for eco-friendly practices. The advancements in hydraulic pump technology not only enhance efficiency and performance but also reduce environmental impact. Manufacturers are increasingly adopting biodegradable hydraulic fluids, which minimize the risk of soil and water contamination. Additionally, energy-efficient hydraulic systems are being designed to consume less power during operations, thereby reducing the carbon footprint of both machinery and infrastructure.

Furthermore, innovative recycling methods are being integrated into the hydraulic lifecycle. Companies are focusing on reusing materials from old hydraulic systems, which not only reduces waste but also promotes a circular economy. These sustainable practices in hydraulic technology showcase a commitment to environmental stewardship while still meeting the demands of modern industry. By prioritizing eco-friendliness, the hydraulic sector can significantly contribute to a more sustainable future, balancing technological advancements with the imperative of protecting our planet.

The Future of Best Main Hydraulic Pump Technology Advancements

This chart displays the advancement in sustainability practices across various hydraulic pump technologies from 2018 to 2023, highlighting the shift towards eco-friendly technologies in the hydraulic industry.

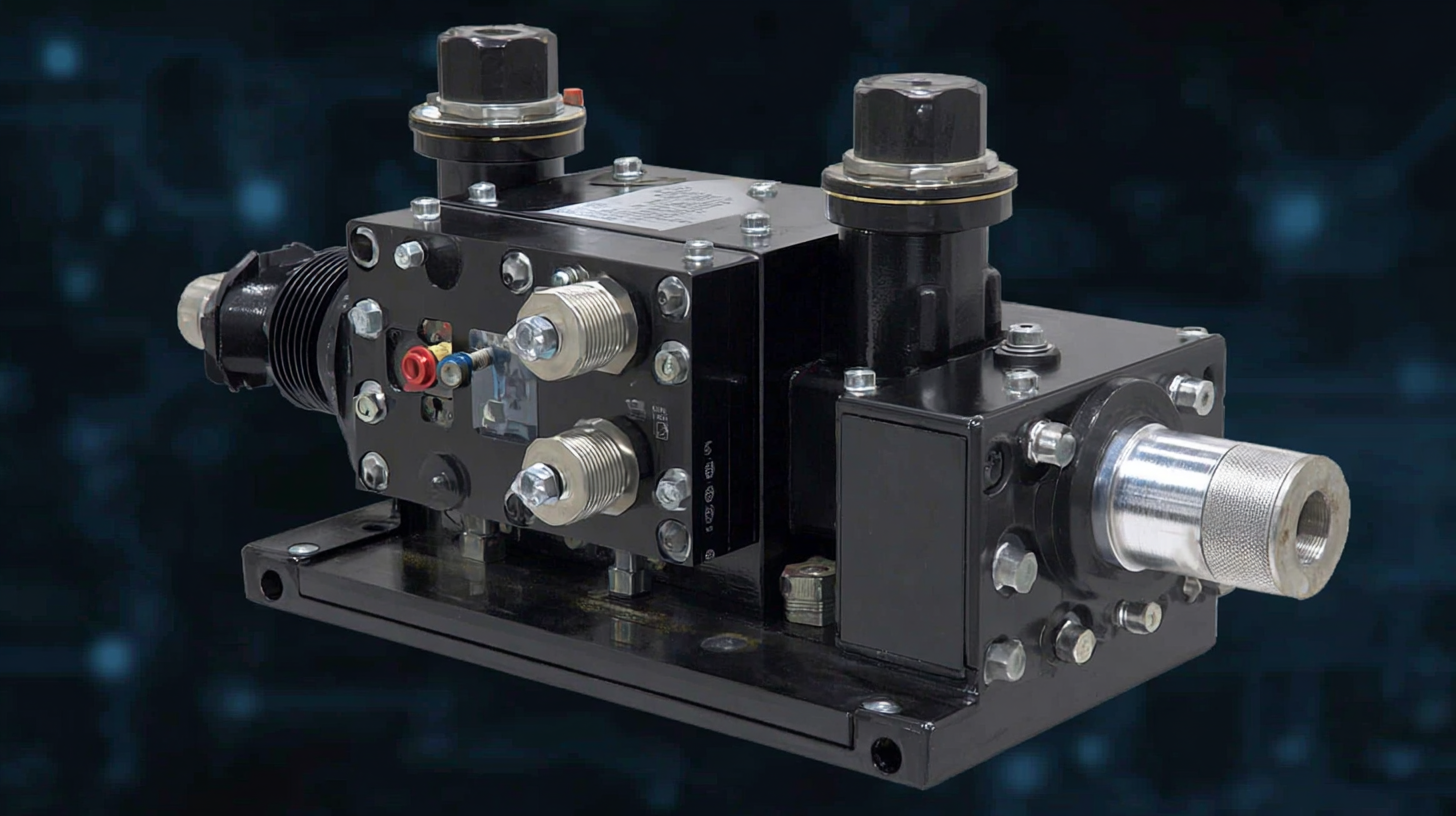

Emerging Trends in Pump Automation and Control Systems for Enhanced Efficiency

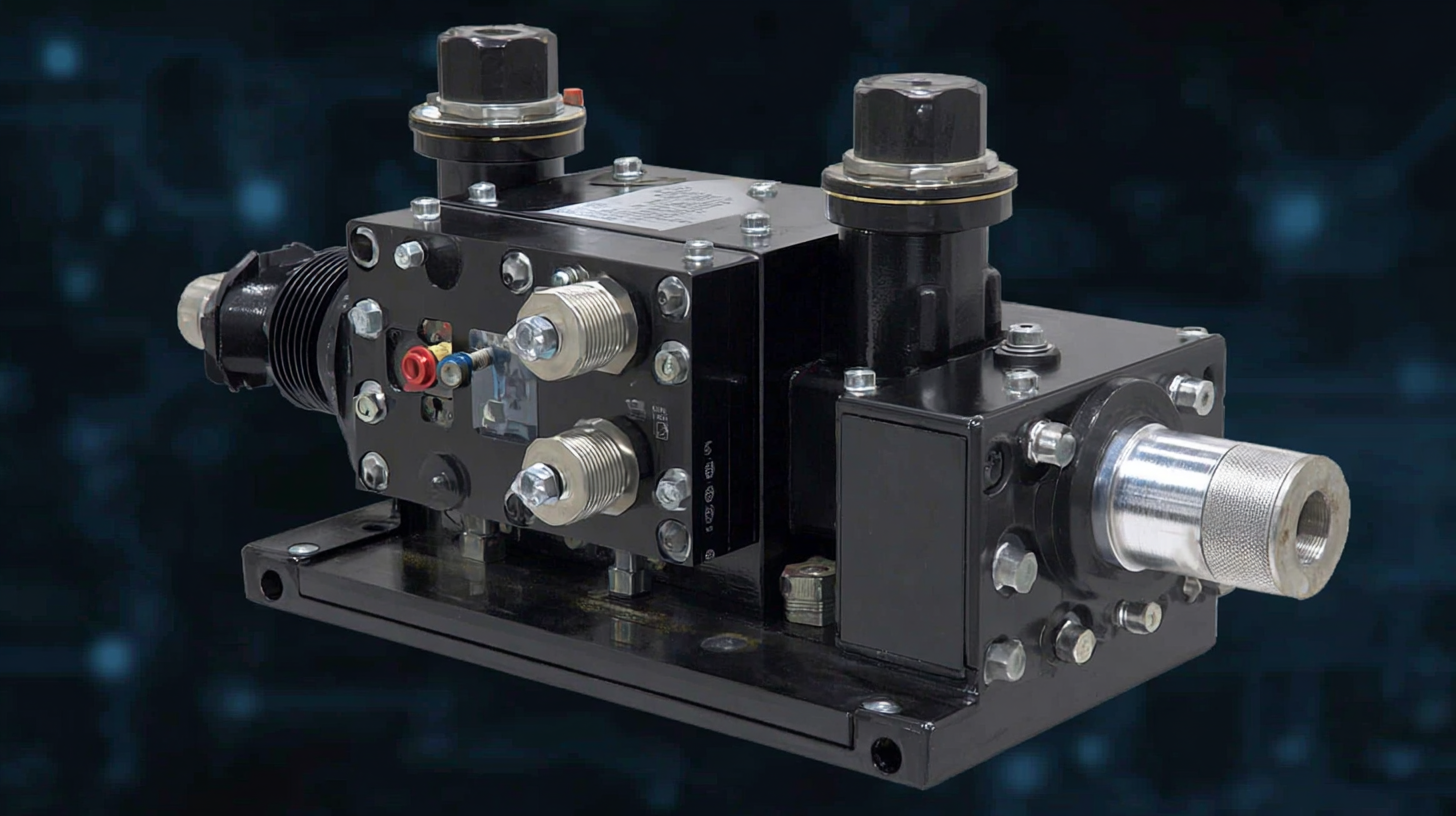

The landscape of hydraulic pumps is evolving rapidly, driven by advancements in automation and control systems. Emerging technologies are setting the stage for enhanced efficiency in pump operations, allowing for real-time monitoring and adjustment of pump performance. By harnessing the power of IoT and data analytics, operators can now achieve optimal performance while minimizing energy consumption and downtime.

One notable trend is the integration of smart sensors that provide critical data on pump health and operational parameters. This allows for predictive maintenance, reducing unexpected failures and prolonging the lifespan of equipment. To effectively utilize these advancements, it's essential to invest in training for operators, ensuring they can interpret data and implement necessary adjustments confidently.

Additionally, automation has reduced the need for manual intervention, streamlining processes and enhancing safety. By implementing automated controls, companies can adjust output in response to real-time demands, significantly boosting efficiency. Here’s a tip: when considering upgrades to your hydraulic systems, prioritize scalable automation solutions that can grow with your business needs, ensuring long-term viability and efficiency improvements.