Comprehensive Guide to Selecting the Right Hydraulic Pump System for Your Project

In the ever-evolving landscape of hydraulic systems, the selection of an appropriate Hydraulic Pump System is critical for the success of any project, whether it's in construction, manufacturing, or automotive applications. According to a recent report from the International Fluid Power Society, the global hydraulic pump market is projected to reach USD 12 billion by 2026, reflecting a growing demand driven by industries striving for efficiency and performance. Selecting the right hydraulic pump not only affects operational efficiency but also influences the overall cost-effectiveness and reliability of the system. With numerous options available—from gear pumps to piston pumps—understanding the specific requirements of your project becomes paramount. This guide will navigate you through key considerations and industry insights essential for making an informed choice in hydraulic pump technology, ensuring that your project is completed on time and within budget.

Understanding Different Types of Hydraulic Pump Systems and Their Advantages

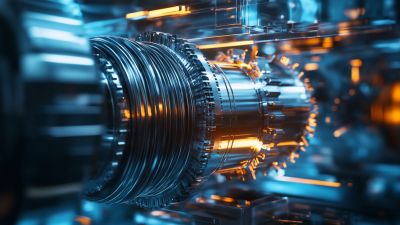

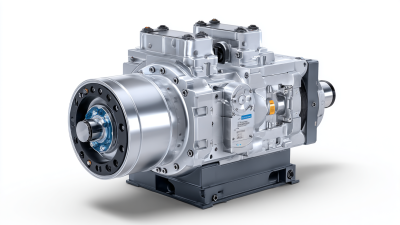

When selecting the right hydraulic pump system for your project, it's crucial to understand the different types of hydraulic systems available and how their unique advantages can benefit your application. Electro-hydraulic systems, for instance, have gained significant attention due to their contributions to the electrification of heavy machinery. These systems not only enhance efficiency but also reduce fuel consumption—a pressing need in modern industrial operations. The integration of electric prime movers with hydraulic systems allows for improved adaptability and performance under varying load conditions, making them ideal for applications across agricultural and construction sectors.

Additionally, advancements in sensor technologies are enabling more comprehensive performance monitoring of hydraulic valves and systems. Such innovations help optimize system operation and reduce maintenance costs, ultimately leading to enhanced productivity. The evolution of design concepts, such as electrohydrostatic drives, further illustrates the benefits of modern hydraulic solutions. These systems offer a blend of traditional hydraulic power with the advantages of electric actuation, providing a versatile and energy-efficient solution for various applications. Understanding these systems' characteristics and advantages is essential for making informed decisions that align with project specifications and operational goals.

Key Factors to Consider When Choosing a Hydraulic Pump for Your Project

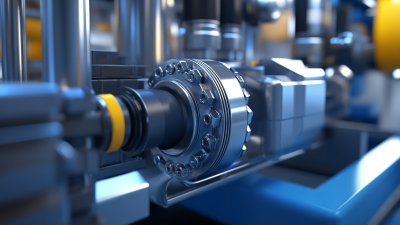

When selecting a hydraulic pump system for your project, several key factors should be considered to ensure optimal performance and efficiency. Firstly, understanding the specific requirements of your application is crucial. According to the Hydraulic Institute’s 2022 Industry Report, around 70% of hydraulic system failures are attributed to improper pump selection, emphasizing the importance of matching the pump type—gear, vane, or piston—to the intended use, whether for high-pressure applications or low-flow scenarios.

Another vital aspect is the pump’s efficiency and energy consumption. A study published by the American Society of Mechanical Engineers (ASME) highlights that up to 30% of energy costs can be reduced by selecting an energy-efficient hydraulic pump. This underscores the need for evaluating the pump’s efficiency ratings and considering advanced models that incorporate variable speed drives to enhance overall performance. Additionally, one should not overlook the importance of maintenance and serviceability features, as systems designed for easier access and repair can significantly decrease downtime and operational costs over the long term.

Maximizing Efficiency: The Benefits of Using Advanced Hydraulic Pump Technologies

When selecting a hydraulic pump system for your project, harnessing advanced hydraulic pump technologies can significantly enhance efficiency. Modern hydraulic pumps are engineered to provide superior performance through innovations such as variable displacement, multi-stage pumping, and smart control systems. These features allow for more precise flow control and energy consumption management, reducing waste and optimizing operational effectiveness.

Additionally, advanced hydraulic systems often incorporate integration with IoT (Internet of Things) technology, enabling real-time monitoring and predictive maintenance. By analyzing performance data, these systems can anticipate failures before they occur, leading to reduced downtime and maintenance costs. Furthermore, the adaptability offered by modern hydraulic solutions makes them suitable for a variety of applications, from construction to manufacturing, ensuring that they meet specific project requirements while delivering peak performance. Embracing these technologies not only maximizes efficiency but also contributes to the sustainability goals of your organization.

Cost-Effectiveness: Long-Term Savings with the Right Hydraulic Pump Selection

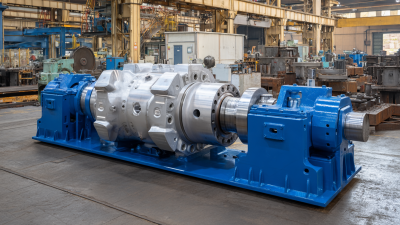

Selecting the right hydraulic pump system is crucial not just for immediate performance but also for long-term cost-effectiveness. According to a recent report by the Hydraulic Institute, choosing the appropriate pump can lead to energy savings of up to 30%. This is particularly relevant in industries where hydraulic systems operate continuously, as the cumulative savings over time can be substantial, potentially exceeding the initial investment by several times.

Moreover, maintenance costs are significantly affected by the choice of pump. The American Society of Mechanical Engineers (ASME) states that poor pump selection can lead to premature wear and tear, resulting in repairs that can account for as much as 40% of total operational costs. By investing in a well-suited hydraulic pump system, companies can reduce unplanned downtime and maintenance interruptions, leading to improved efficiency and productivity. Thus, a careful selection process not only enhances immediate operational capability but ensures sustainable financial performance over the lifespan of the hydraulic pump system.

Comprehensive Guide to Selecting the Right Hydraulic Pump System for Your Project - Cost-Effectiveness: Long-Term Savings with the Right Hydraulic Pump Selection

| Pump Type |

Initial Cost ($) |

Maintenance Cost/Year ($) |

Operational Efficiency (%) |

Estimated Lifespan (Years) |

Total Cost of Ownership over 10 Years ($) |

| Gear Pump |

2,000 |

150 |

85 |

15 |

3,500 |

| Piston Pump |

3,500 |

200 |

90 |

20 |

4,500 |

| Vane Pump |

2,800 |

180 |

80 |

12 |

3,200 |

| Diaphragm Pump |

3,000 |

220 |

75 |

10 |

3,800 |

Common Applications: Where Each Type of Hydraulic Pump Excels

When selecting a hydraulic pump system, understanding the specific applications where each type of pump excels is crucial for optimal performance.

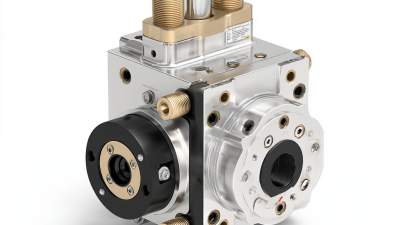

Positive displacement pumps, for instance, are renowned for their ability to maintain a consistent flow rate regardless of pressure changes, making them ideal for applications requiring precise control, such as injection molding or hydraulic presses. Their reliability in transferring viscous fluids also makes them suitable for industrial environments involving heavy machinery and equipment.

On the other hand, centrifugal pumps shine in applications demanding high flow rates and lower pressures. They are commonly used in irrigation systems, cooling systems, and water supply systems, where efficiency in moving large volumes of fluid is paramount. Additionally, their simplicity and ease of maintenance make them a popular choice for many engineering projects.

Understanding the strengths and limitations of each type of hydraulic pump allows project managers and engineers to make informed decisions, ensuring that the chosen system meets the specific requirements of their applications effectively.