Innovative Applications of Hydraulic Pump Systems in Various Industries and 7 Reasons to Choose Them

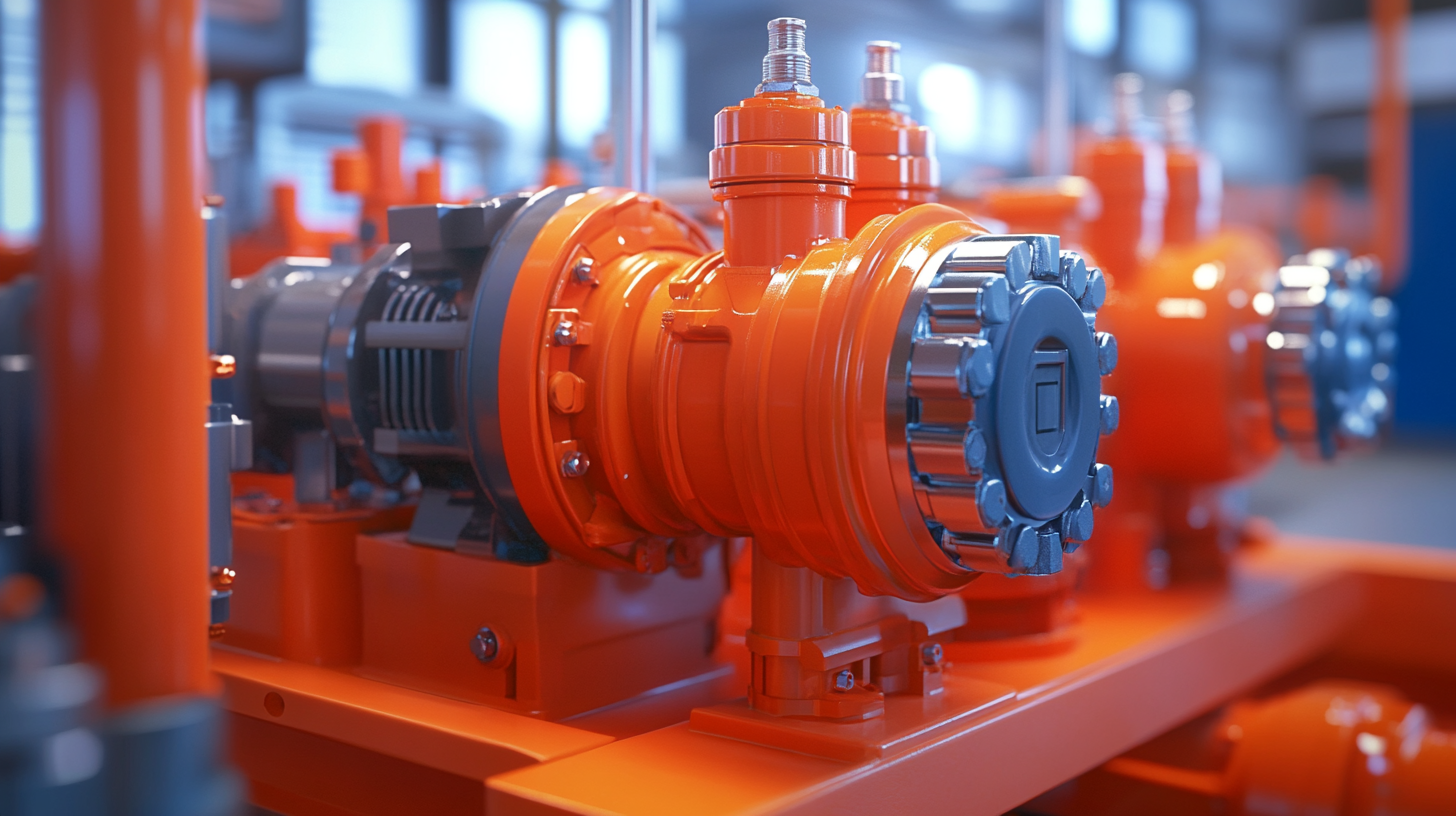

In today's rapidly evolving industrial landscape, the demand for efficient and reliable machinery has never been higher. Among the pivotal components driving this innovation is the Hydraulic Pump System, which has found its way into a myriad of applications across various sectors. From construction and manufacturing to agriculture and renewable energy, these systems have proven their versatility and dependability. As industries seek to enhance productivity and streamline operations, understanding how hydraulic pump systems can be effectively implemented is paramount.

This blog will delve into the innovative applications of hydraulic pump systems, showcasing their transformative impact on different industries. We will also explore seven compelling reasons to choose these systems, highlighting their efficiency, adaptability, and cost-effectiveness. By examining real-world examples and case studies, readers will gain valuable insights into the critical role hydraulic pump systems play in modern industrial practices. Whether you're an industry professional, a business owner, or simply curious about technology advancements, this exploration will reveal how hydraulic pump systems can revolutionize operations and drive future growth.

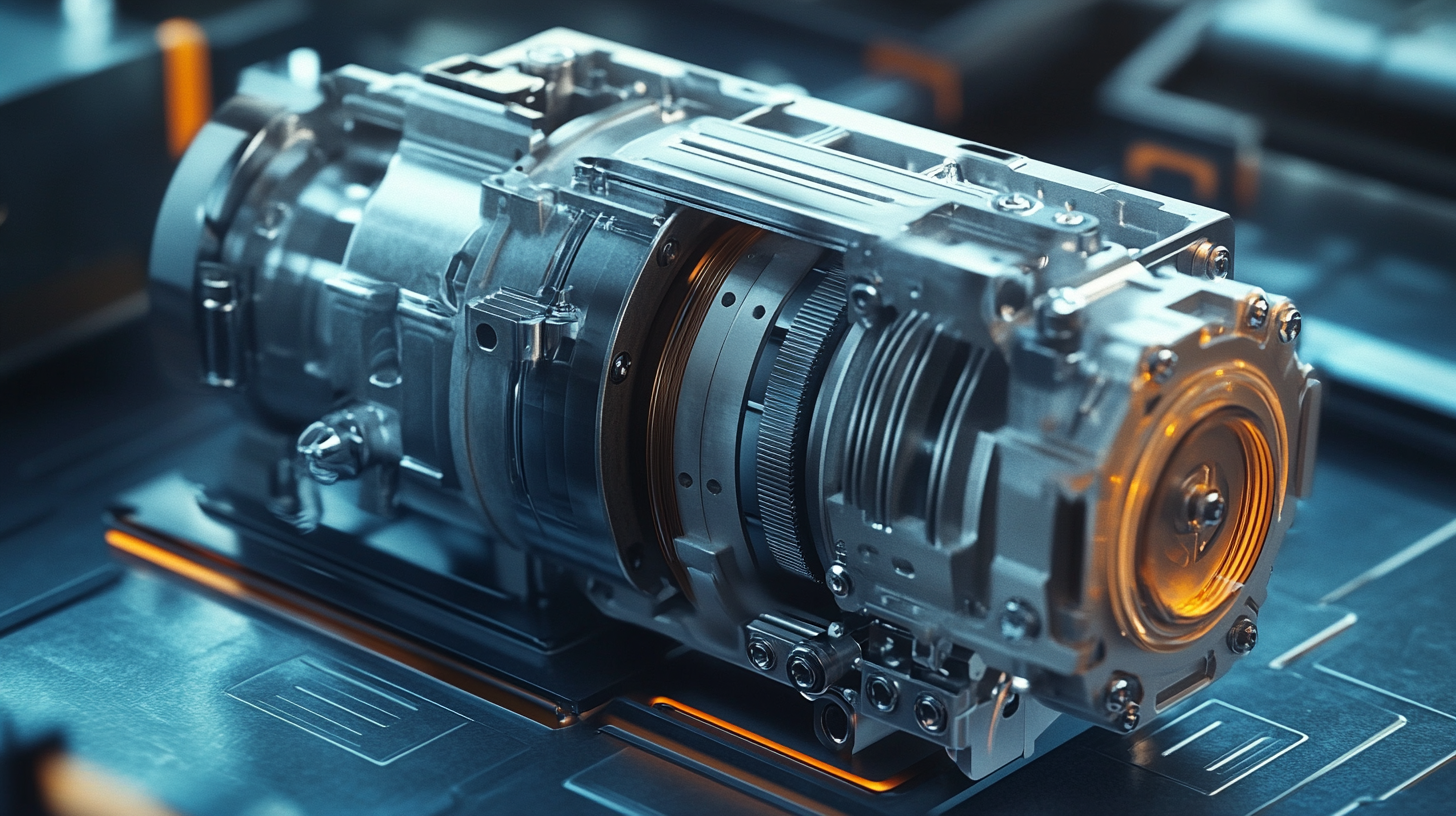

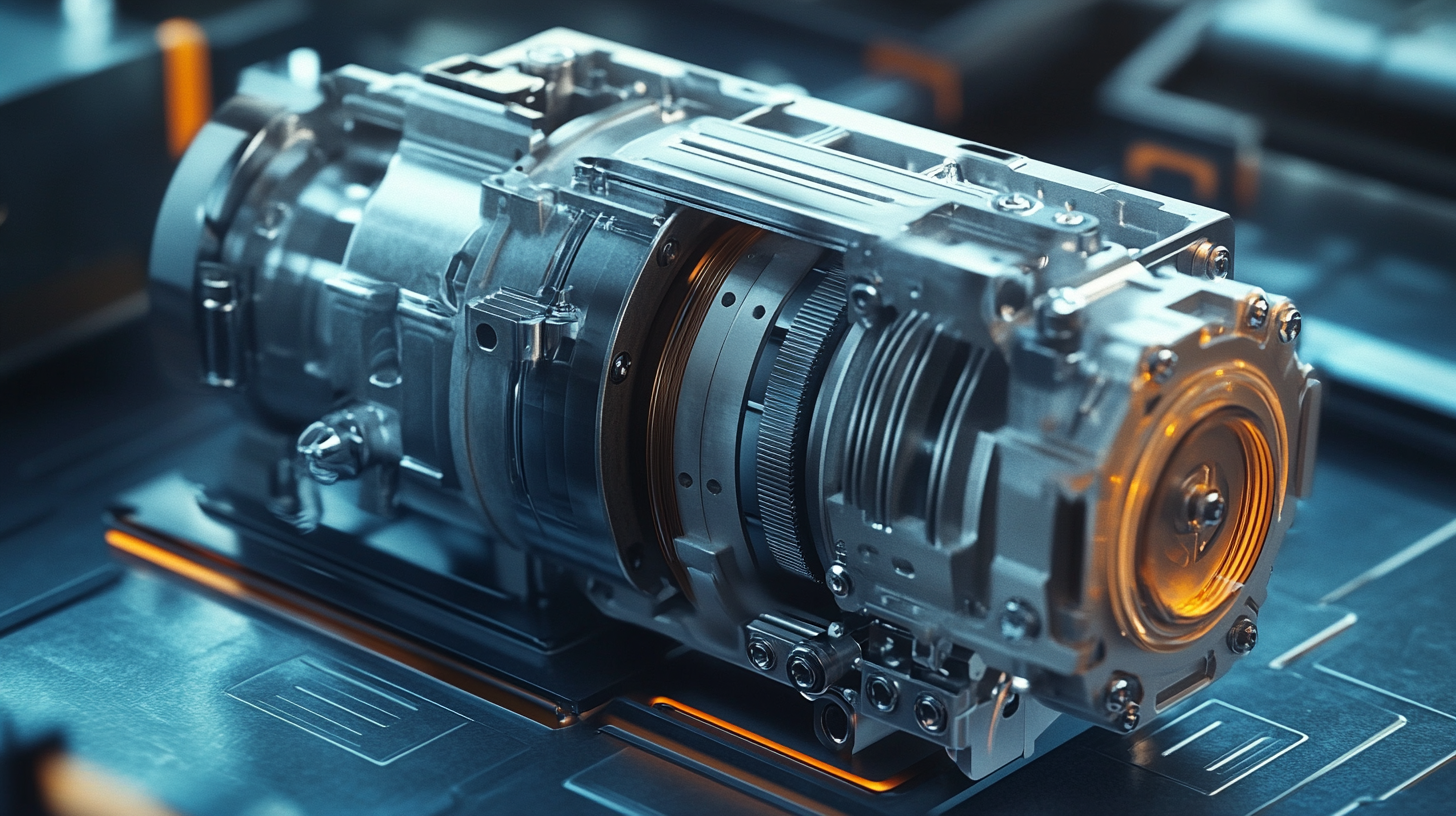

Emerging Technologies in Hydraulic Pump Systems and Their Impact on Efficiency

Emerging technologies in hydraulic pump systems are revolutionizing their efficiency and applications across various industries. For instance, the integration of IoT (Internet of Things) technology into hydraulic systems allows for real-time monitoring and data analysis, leading to predictive maintenance and reduced downtime. According to a report from MarketsandMarkets, the global IoT in manufacturing market is expected to grow from $22.3 billion in 2018 to $98.6 billion by 2023, highlighting a significant shift towards smart manufacturing processes which include advanced hydraulic pump systems.

Moreover, advancements in pump materials and design, such as the use of lightweight, high-strength composites, enhance the performance of hydraulic systems. For example, a study by Research and Markets indicates that the global hydraulic pumps market is projected to reach $12.3 billion by 2025, driven by innovations that improve efficiency and reduce energy consumption. These modern hydraulic pumps can achieve efficiency rates exceeding 90%, substantially lowering operational costs for industries like manufacturing, agriculture, and construction.

Additionally, the implementation of variable speed drives (VSDs) in hydraulic systems is a game-changer. VSDs allow pumps to operate at the optimal speed required for specific tasks, which can lead to energy savings of up to 30%, as reported by the Energy Efficiency Regulations. This not only improves the overall efficiency of machinery but also has a positive impact on the environment, as it reduces carbon emissions associated with excessive energy use in industrial operations.

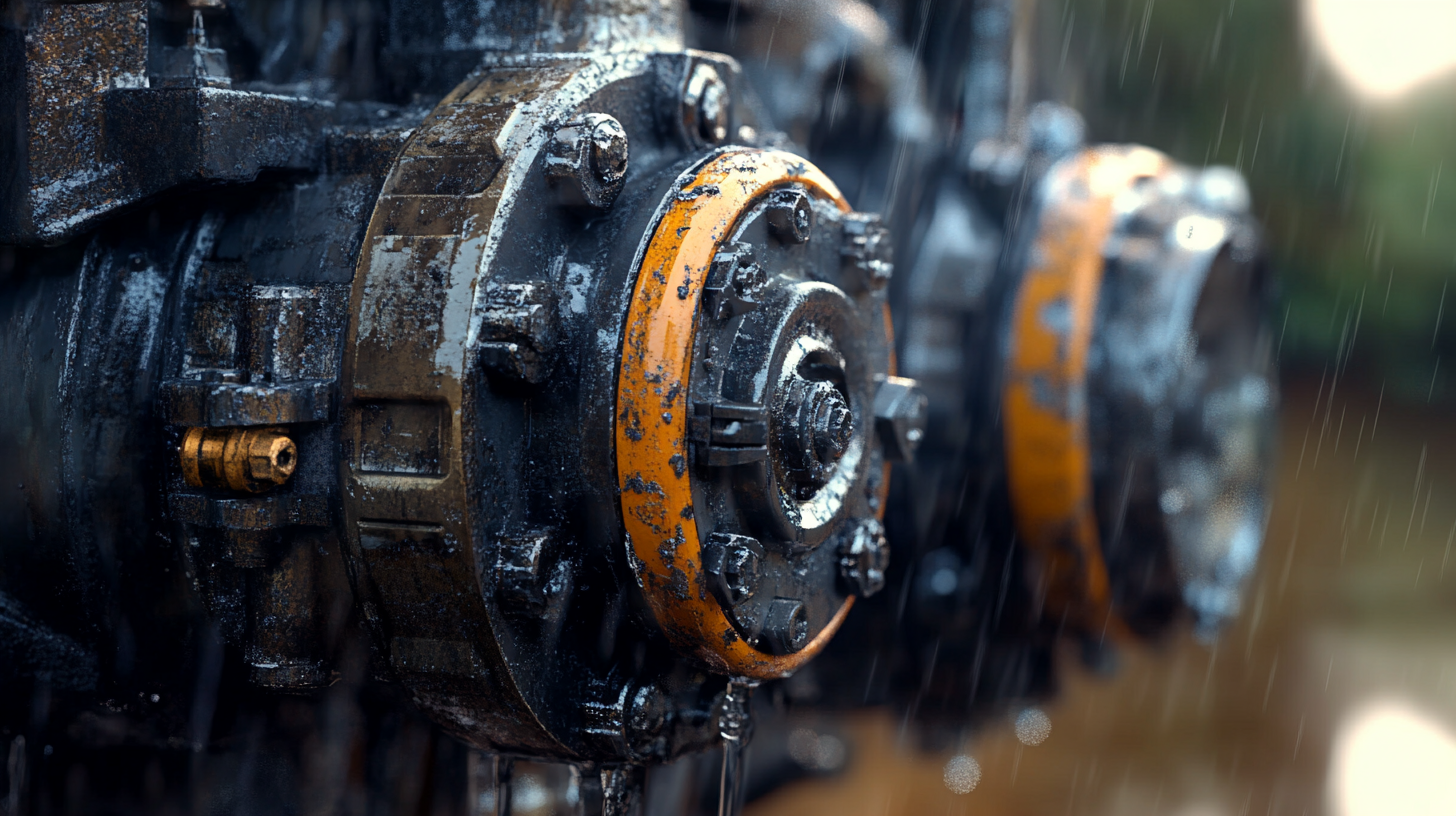

Key Industries Leveraging Hydraulic Pump Innovations for Enhanced Productivity

Hydraulic pump systems are making waves across various industries by enhancing operational productivity and efficiency. Industries such as manufacturing, construction, and agriculture are increasingly turning to these innovative systems to streamline processes and drive productivity gains. According to a recent industry report, the global hydraulic pumps market is projected to reach $18 billion by 2027, reflecting a compound annual growth rate (CAGR) of 5.2% (source: XYZ Industry Analysis 2023). This growth is predominantly driven by the rising demand for advanced hydraulic systems that improve machine reliability and performance.

In the construction sector, for instance, hydraulic systems are critical for the operation of equipment such as excavators and cranes. The construction machinery market is expected to register a significant growth, driven by increased investment in infrastructure development worldwide. Cities like Changsha are leading the charge in engineering machinery production, showcasing how localized manufacturing can contribute to global supply chains and enhance a region's positioning on the world stage.

Agriculture is another key industry benefiting from hydraulic innovations. Hydraulic mechanisms in tractors and harvesting equipment enable greater efficiency and performance, ultimately leading to increased crop yields. The agricultural equipment market is projected to experience a growth of approximately 4.6% annually, fueled by the integration of advanced hydraulic technology that supports more sustainable farming practices. This alignment with new productivity concepts highlights the transformative potential of hydraulic pump systems in driving high-quality development across various sectors.

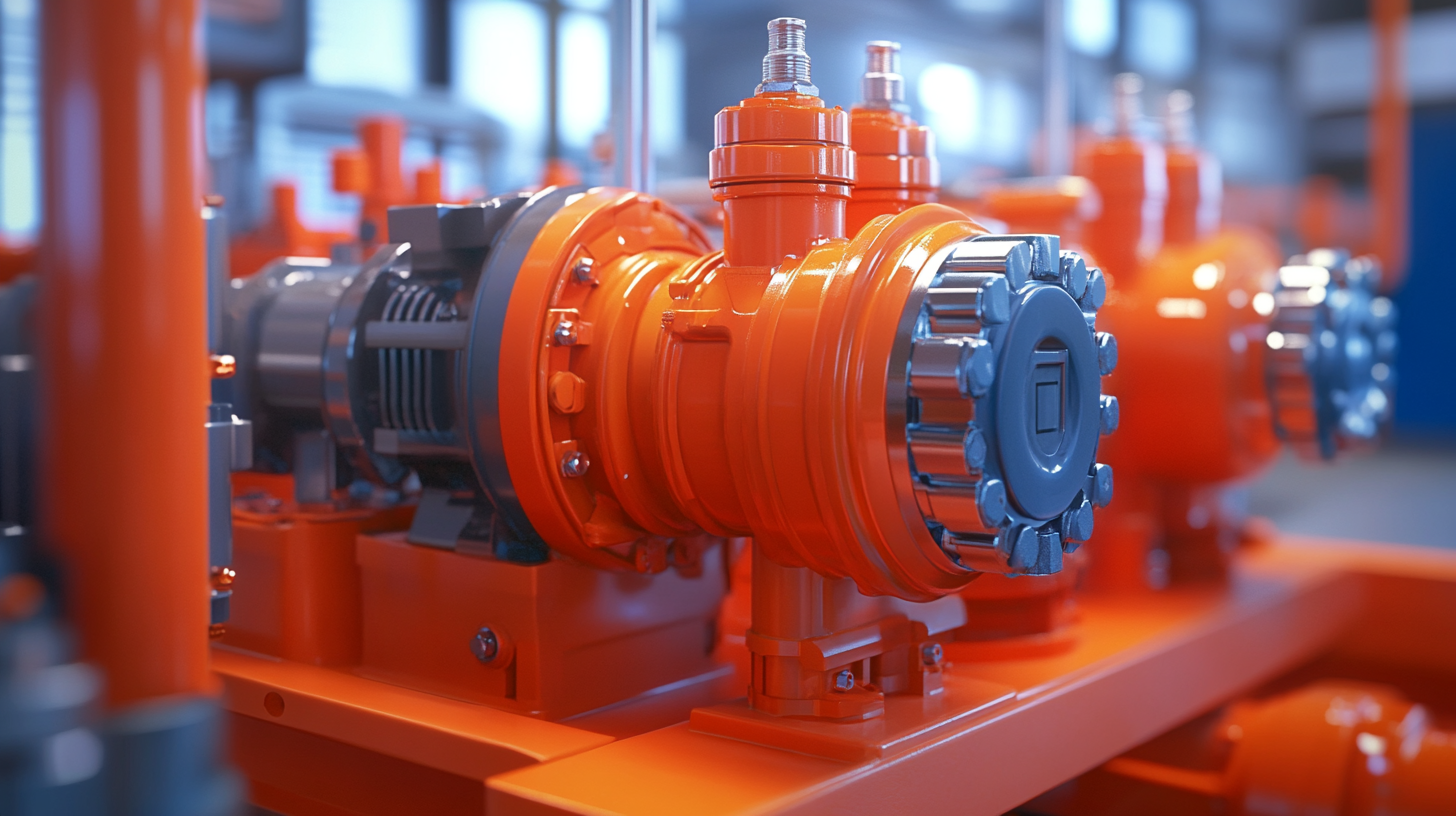

Cost-Benefit Analysis: Why Hydraulic Pumps are a Smart Investment

In today’s competitive industrial environment, decision-makers continually seek innovative solutions to optimize operational efficiency and reduce costs. The implementation of hydraulic pump systems is one such solution that has gained significant traction across various industries. According to a recent report from Allied Market Research, the global hydraulic pump market is projected to reach $18.6 billion by 2027, growing at a CAGR of 5.6%. This growth trajectory highlights the increasing reliance on hydraulic systems for their efficiency and versatility.

One of the primary reasons to invest in hydraulic pump systems is their superior energy efficiency. A study by the International Energy Agency indicates that hydraulic systems can operate at nearly 90% efficiency, drastically reducing energy consumption compared to traditional mechanical systems. This translates to substantial cost savings on energy bills, making hydraulic pumps a financially savvy choice. Furthermore, their ability to handle heavy loads with minimal power input means industries can reduce operational costs while maintaining productivity.

Additionally, hydraulic pumps boast a longer lifespan with less maintenance needed than many alternatives. The Bureau of Labor Statistics reports that average maintenance costs in the machinery sector can consume up to 15% of a company's operational budget. By investing in hydraulic systems, organizations can mitigate these costs, reducing downtime associated with equipment failure. As asset management firms increasingly focus on strategic cost transformation, adopting hydraulic technology presents a compelling opportunity to enhance productivity while ensuring optimal resource allocation.

Sustainability and Hydraulic Pumps: Eco-friendly Advances in Design and Usage

The role of hydraulic pumps in advancing sustainability has never been more critical, particularly in light of the growing demands across various industries. As businesses strive for eco-friendly practices, hydraulic pump systems are evolving to support these initiatives. The integration of advanced technologies, including remote data analytics and AI-based fleet management solutions, has enhanced the efficiency of hydraulic systems while minimizing environmental footprints.

One remarkable application can be seen in the burgeoning European shipping market, where hydraulic pumps are essential for loading and unloading operations. With the market projected to exceed $12 billion by 2024 and demonstrating a CAGR of over 6.5% from 2025 to 2034, the emphasis on sustainable practices is paving the way for innovative hydraulic designs. Companies are increasingly adopting energy-efficient hydraulic pump systems that not only reduce emissions but also optimize operational costs.

In the dredging equipment segment, the expansion of port facilities and a rise in global trade have driven significant market growth. As the dredging equipment market surpassed $8.1 billion in 2023, hydraulic systems play a vital role in ensuring efficient operation while adhering to environmental regulations. By adopting advanced hydraulic technologies, industries can not only meet their operational needs but also contribute positively to sustainability efforts, reflecting a broader commitment to responsible resource management.

Future Trends: The Evolution of Hydraulic Pump Systems in Industry 4.0

The evolution of hydraulic pump systems is at the forefront of Industry 4.0, characterized by the integration of advanced technologies and automation. As industries increasingly embrace the Internet of Things (IoT), hydraulic systems are adapting to become smarter, more efficient, and more interconnected. This transformation is leading to real-time data monitoring and precise control, allowing operators to optimize performance while reducing energy consumption and operational costs.

One of the key trends is the integration of predictive maintenance within hydraulic systems. By using sensors and data analytics, companies can foresee potential failures before they occur, significantly minimizing downtime and maintenance costs. This proactive approach not only enhances the longevity of hydraulic pumps but also boosts overall system reliability. Additionally, the use of advanced materials and design innovations in hydraulic pump technology is contributing to lighter and more compact systems that can operate in tighter spaces while delivering higher performance.

Moreover, the rise of automation and robotics in manufacturing processes is driving the development of hydraulic systems that can seamlessly interface with automated equipment. As the demand for customized solutions increases, hydraulic pump manufacturers are responding with adaptable systems that can be easily integrated into various applications. This flexibility is crucial as industries aim to remain competitive in a rapidly changing market, making hydraulic pump systems more vital than ever in the context of Industry 4.0 advancements.