Exploring Innovations in Main Hydraulic Pump Technology for Global Buyers in 2025

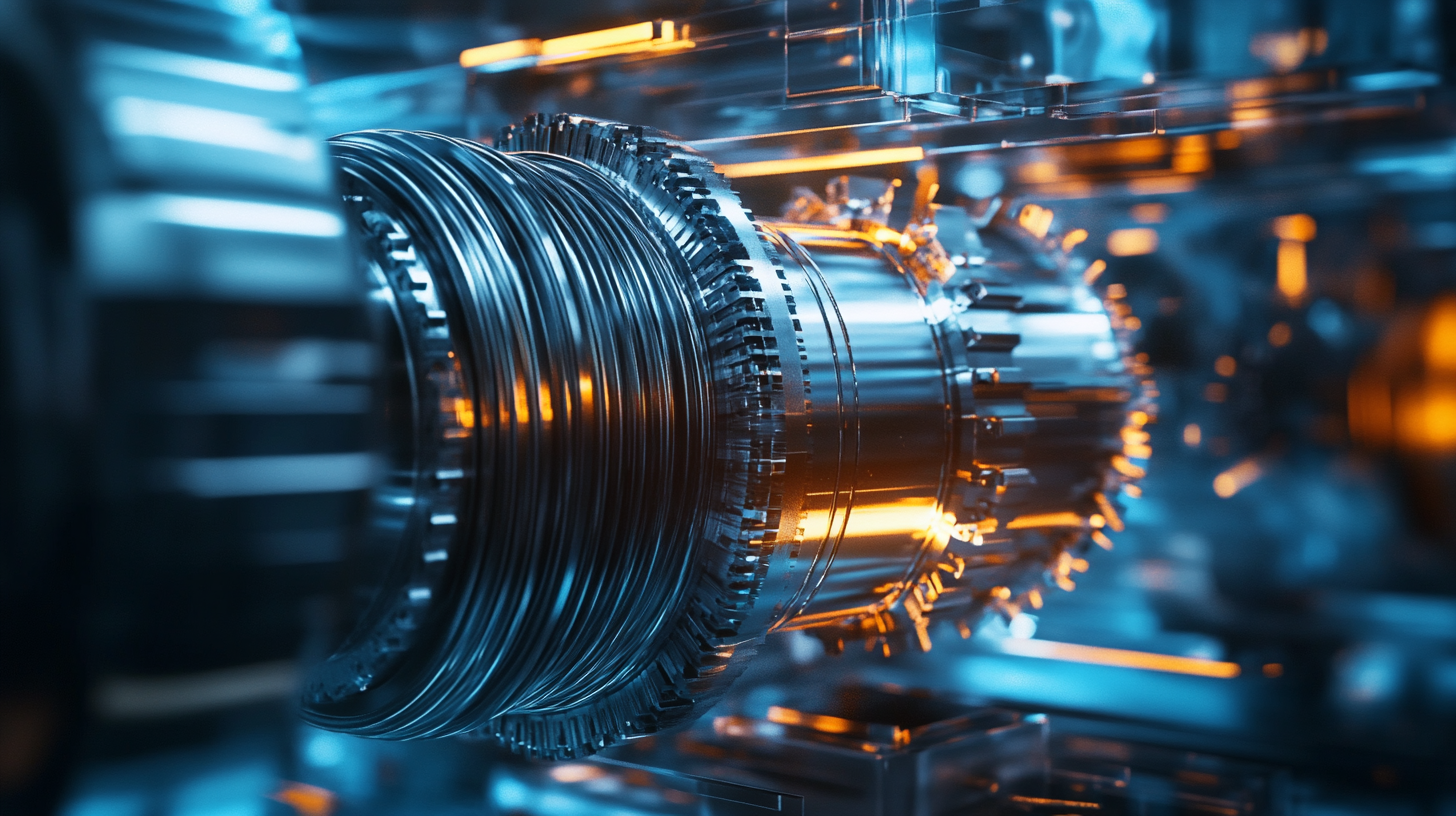

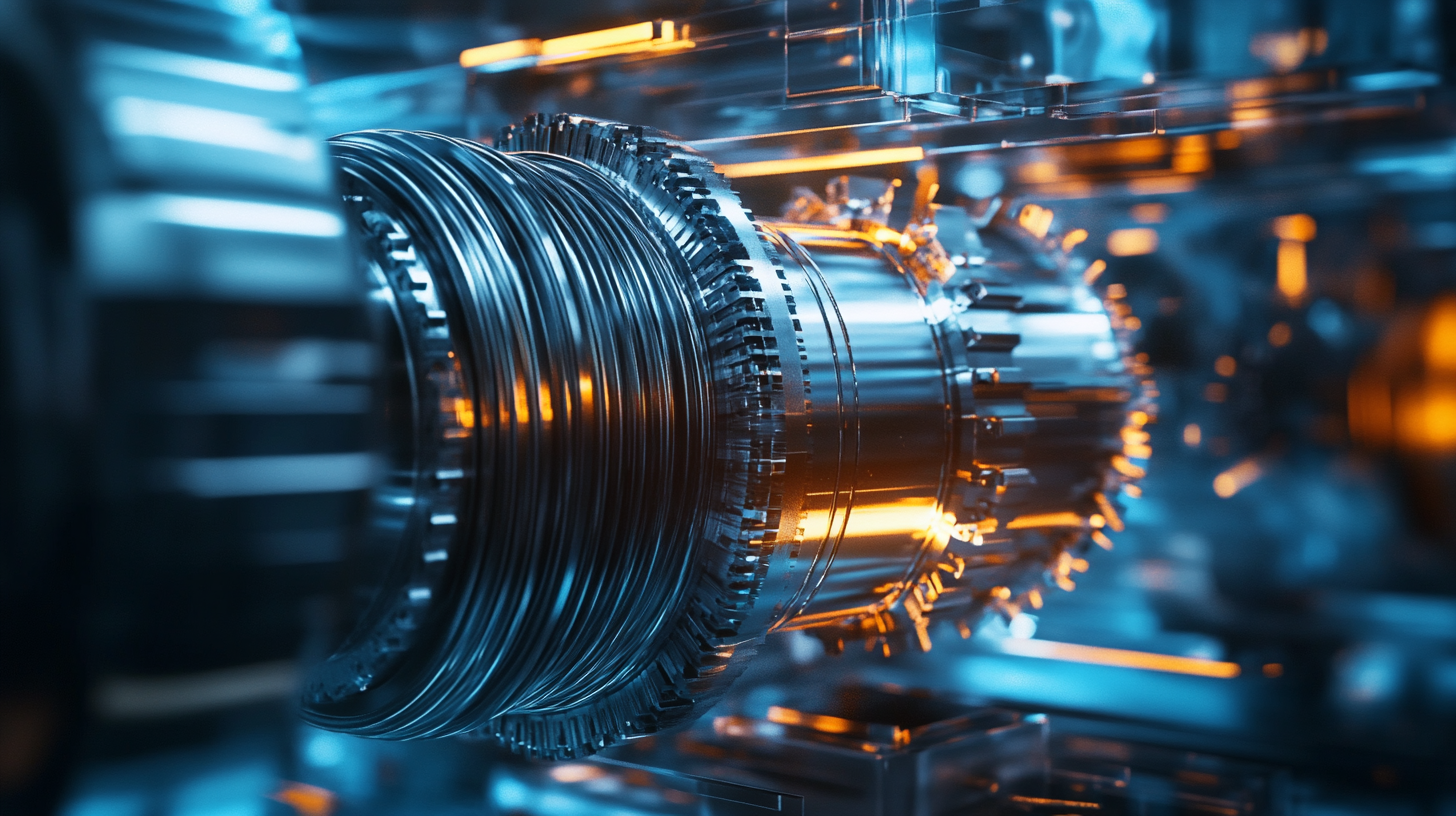

As we step into 2025, the landscape of hydraulic technology is undergoing a remarkable transformation, with a keen focus on enhancing efficiency and performance. At the heart of this evolution lies the Main Hydraulic Pump, a critical component that powers various applications in sectors ranging from construction to manufacturing. This blog delves into the latest innovations and advancements in Main Hydraulic Pump technology, showcasing how these developments are shaping the future for global buyers.

In a world increasingly driven by sustainability and automation, understanding the advancements in Main Hydraulic Pump design and functionality becomes paramount for businesses seeking to optimize their operations. By examining key trends, emerging technologies, and market demands, we aim to provide insightful perspectives that can help buyers make informed decisions. Join us as we explore the innovations set to redefine hydraulic systems and propel industries forward in the coming years.

Emerging Trends in Hydraulic Pump Design: Enhancing Efficiency for Global Markets in 2025

The hydraulic pump industry is undergoing significant transformation as we approach 2025, driven by emerging technologies and the urgent need for improved efficiency. In this rapidly evolving market, manufacturers are increasingly focusing on innovative designs that not only boost performance but also reduce energy consumption. This trend is particularly crucial as global buyers seek sustainable solutions amid growing environmental concerns.

One major innovation in hydraulic pump design is the integration of smart technology. By incorporating IoT capabilities, pumps can now provide real-time data on their performance, allowing for predictive maintenance and timely troubleshooting. This enhances not only the efficiency of pump operations but also extends the lifespan of the equipment. Moreover, advancements in materials science are enabling the production of lighter, more robust components, which further contribute to energy efficiency and overall performance.

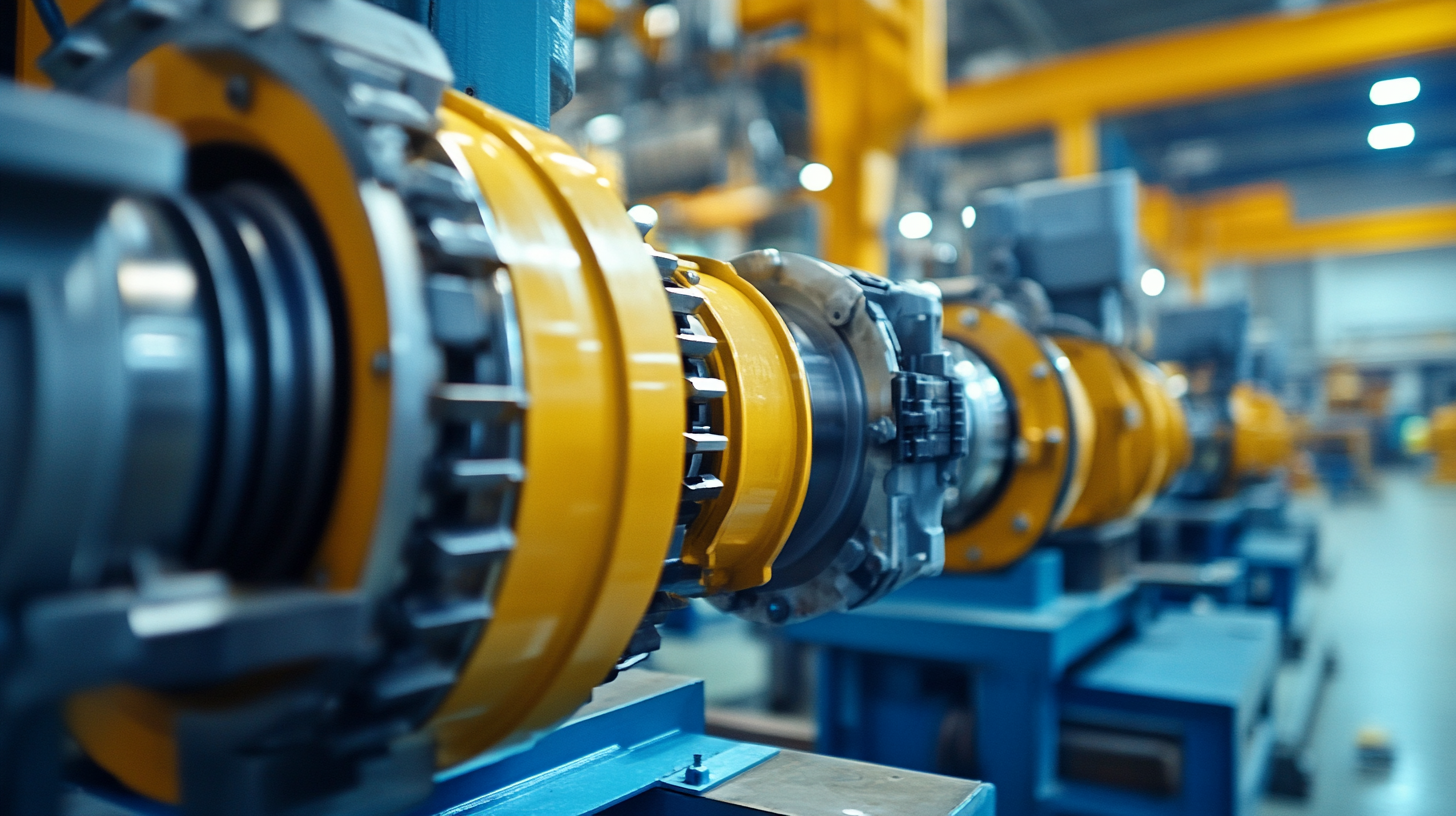

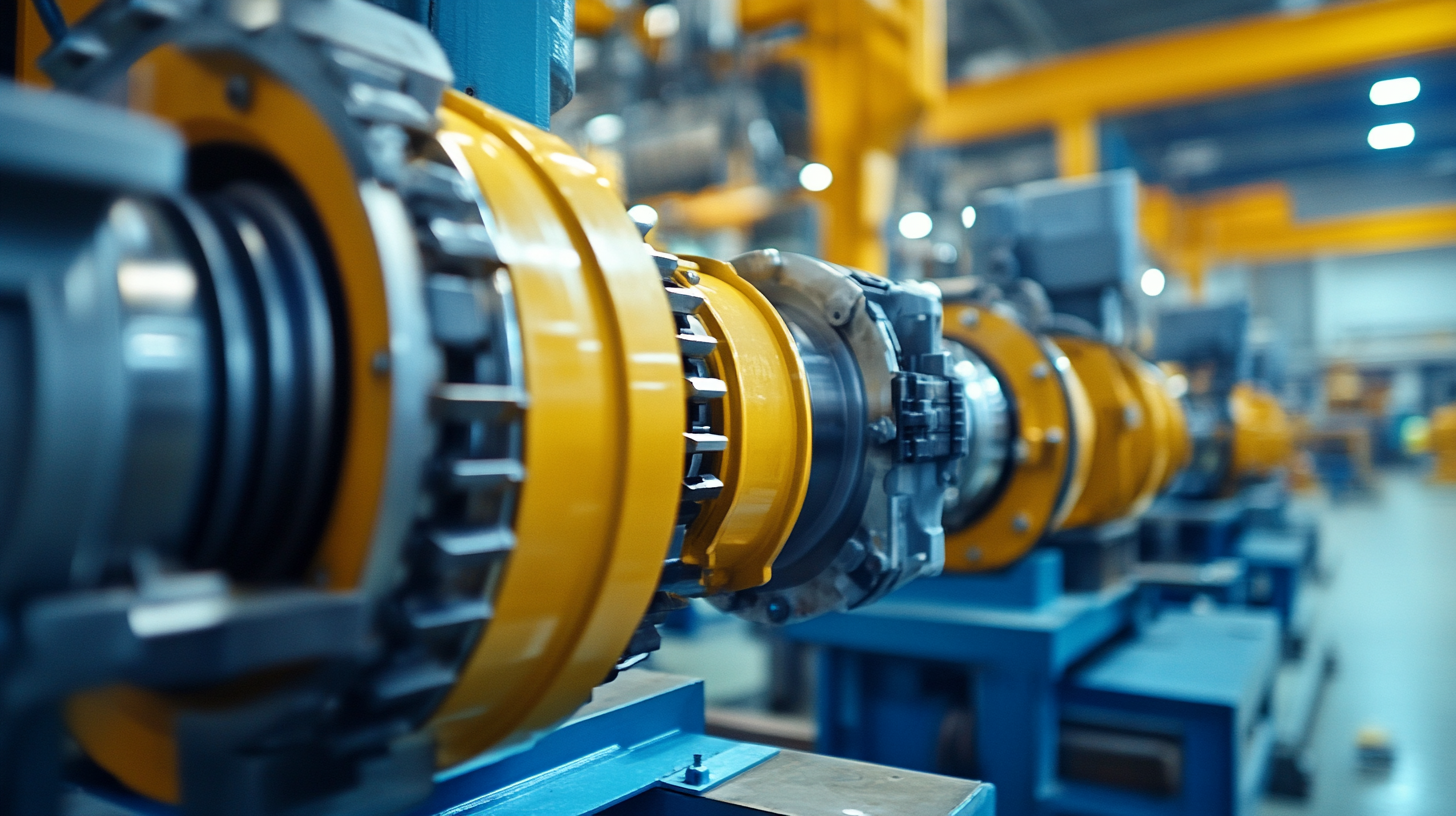

Another notable trend is the shift towards modular designs, which offer flexibility and adaptability. Modular hydraulic pumps allow users to customize their systems based on specific operational needs, reducing waste and optimizing resource utilization. This adaptability is particularly appealing to global markets where varying applications demand quick adjustments without significant downtime or additional costs. As these innovations take center stage, they pave the way for a more efficient and sustainable future in hydraulic pump technology.

Market Demand Analysis: The Surge of Hydraulic Pump Technologies in Various Industries

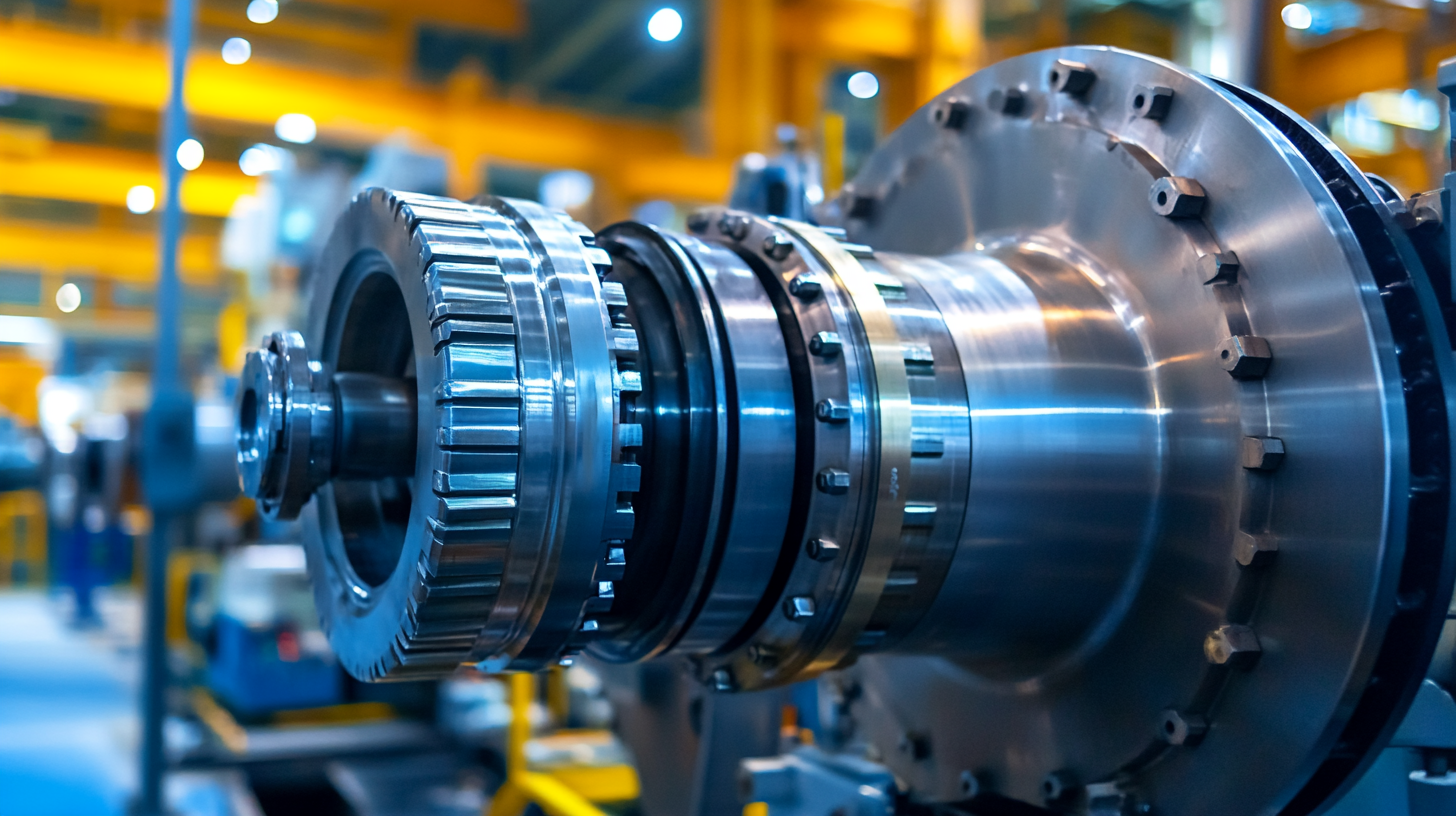

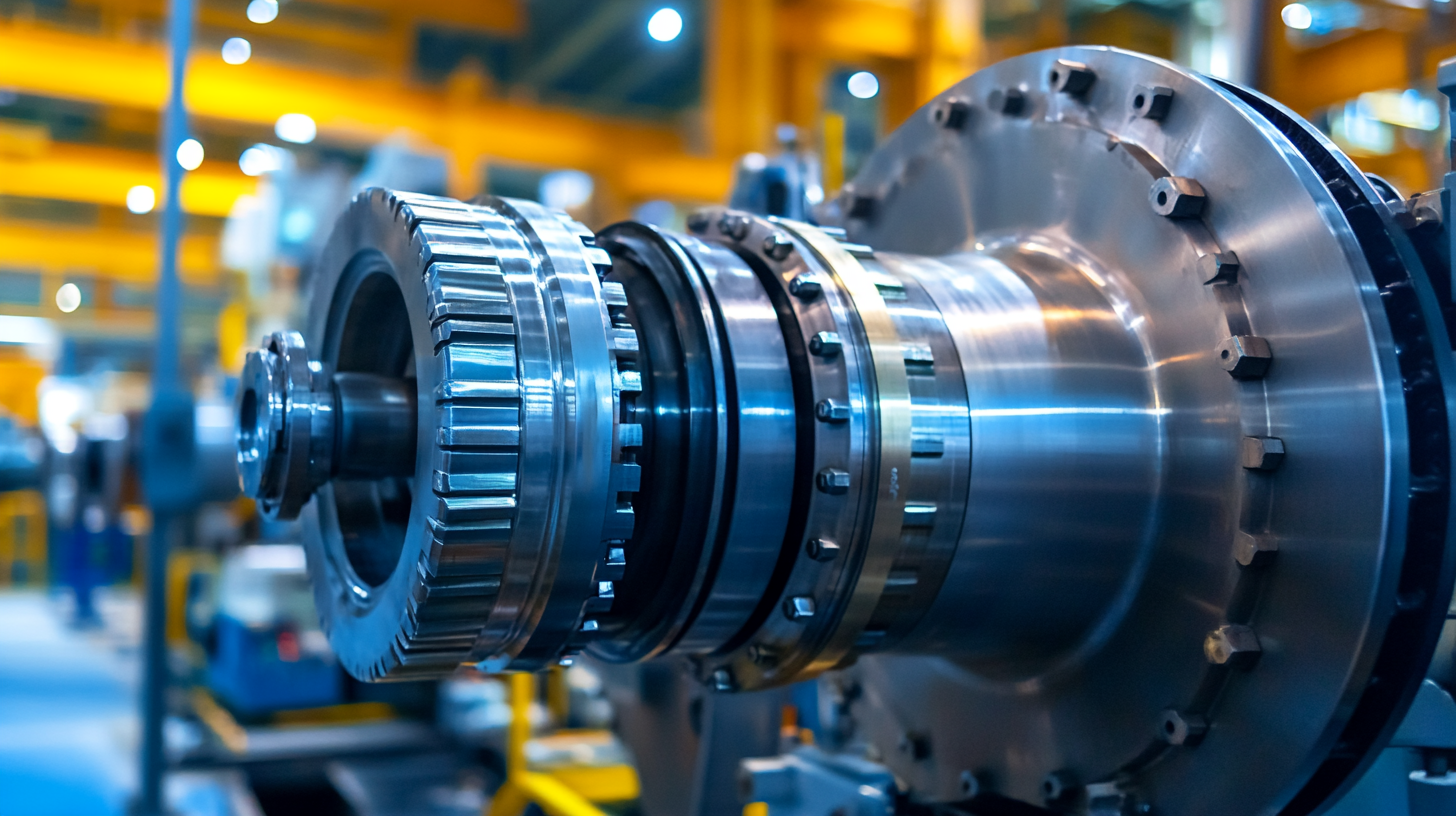

As we move towards 2025, the demand for hydraulic pump technologies is witnessing a significant surge across various industries. This growth is driven by advancements in hydraulic and pneumatic sealing components, which are becoming essential for the performance of hydraulic equipment. With an increasing emphasis on enhancing efficiency and durability, the domestic market is rapidly progressing towards higher levels of localization in hydraulic equipment manufacturing. This is evidenced by the demand for hydraulic seals, which continues to rise, signaling a robust evolution within the sector.

Key players like Aisin Seiki, BorgWarner, and Delphi Technologies are leading the way in innovation, striving to meet the increasing needs of the automotive sector and beyond. Market reports forecast that the automotive pump market size will expand considerably from 2024 to 2032, suggesting a shift in how hydraulic technologies are integrated into vehicles to enhance performance. As industries look for more reliable and efficient solutions, hydraulic pumps equipped with cutting-edge technology will become even more integral, paving the way for advancements across manufacturing processes.

The ongoing development of hydraulic systems is poised to impact diverse sectors beyond automotive, including construction, agriculture, and aerospace. With the continuous push for improved power transmission and control, industries are expected to diversify their applications of hydraulic technology. The innovations in hydraulic pump technology not only reflect the growing market demands but also signal a transformational phase in how heavy machinery and equipment operate. The opportunities for global buyers are vast, as they seek to leverage these technological advancements for greater productivity and competitive edge.

Impact of IoT and Smart Technology on Hydraulic Pump Innovations by 2025

Looking towards 2025, it’s pretty clear that the hydraulic pump industry is on the brink of something big—a technological revolution, to be exact! Thanks to the rise of IoT and smart tech, we're seeing a real shift in how hydraulic systems do their thing. They’re becoming way more efficient, reliable, and honestly, just easier to use. With smart sensors and data analytics in the mix, hydraulic pumps are transforming from basic mechanical parts into intelligent systems that can actually chat with you, learn from their surroundings, and adjust to changes in how they work.

One of the coolest things happening is how IoT is ramping up predictive maintenance. With real-time data from those snazzy smart sensors, manufacturers and operators can keep an eye on pump performance non-stop. This means they can spot potential problems before they snowball into expensive failures. It’s a game-changer—shifting from a reactive approach to a proactive one not only cuts down on downtime but also helps pumps last longer, saving some serious cash in the process.

And it doesn't stop there! Thanks to smart technology, managing and controlling hydraulic systems remotely is now totally doable. Operators can check out crucial performance data from wherever they are, which makes quick decisions and adjustments a breeze without needing to be physically present. This kind of connectivity not only amps up operational efficiency but opens the door for better energy usage and overall sustainability in hydraulic applications. As the industry hops on board with these innovations, the story of increased productivity and a smaller environmental footprint becomes super appealing to global buyers looking to invest in cutting-edge hydraulic solutions in the years to come.

Sustainability in Hydraulic Pump Manufacturing: Meeting Global Environmental Standards

As global consumers increasingly prioritize sustainability, the hydraulic pump industry faces pressure to adapt and innovate. The market for hydraulic pumps is projected to reach $52.3 billion by 2025, according to a recent report by MarketsandMarkets. This growth necessitates not only advancements in performance but also adherence to stringent environmental standards. Manufacturers are investing in eco-friendly materials and processes, aligning with the International Organization for Standardization’s (ISO) environmental management specifications, such as ISO 14001, which outlines how organizations can enhance their environmental performance.

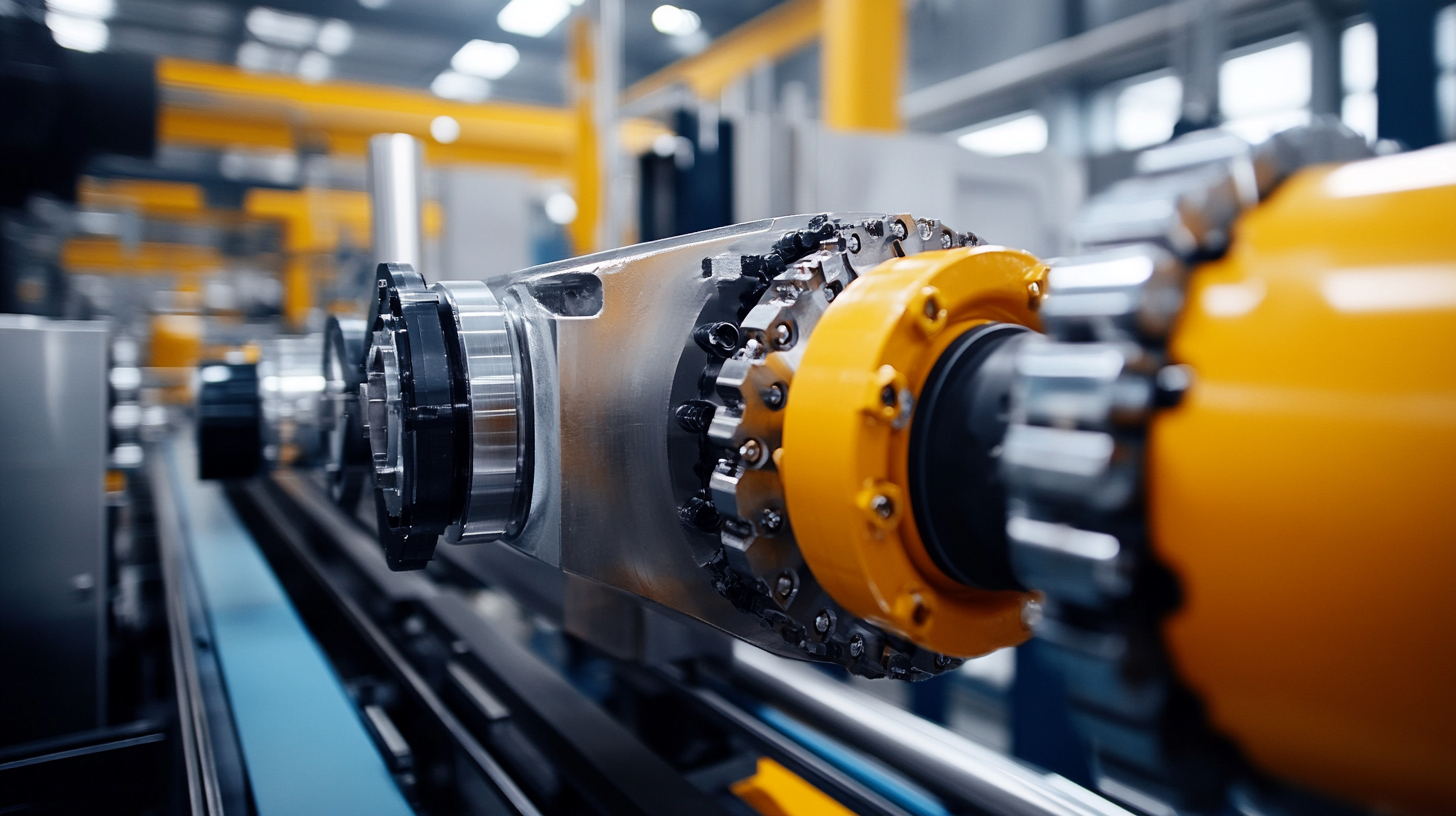

In the manufacturing process, energy efficiency is critical. The U.S. Department of Energy has identified that upgrades to hydraulic systems can lead to energy savings of up to 20%, highlighting a route for manufacturers to reduce their carbon footprint. Additionally, introducing innovations like variable speed drives (VSDs) allows hydraulic pumps to adjust their output based on real-time demand, further increasing energy efficiency. This technology not only conserves energy but also minimizes waste, which is often a byproduct of traditional fixed-speed systems.

Recycling and reusing materials is another focus area, as research from the Hydraulic Institute indicates that sustainable practices can reduce material waste by up to 40%. As a result, companies are exploring biodegradable fluids and recyclable components in pump designs. This shift not only meets global environmental standards but also positions manufacturers as leaders in sustainable practices within the hydraulic industry, appealing to environmentally conscious buyers and investors alike.

Key Competitors and Strategic Partnerships Shaping the Hydraulic Pump Industry Landscape

In the rapidly evolving hydraulic pump industry, strategic partnerships are becoming essential for companies aiming to increase their market share and drive innovation. Key players are realigning their resources and forming alliances to leverage complementary strengths, ensuring they remain competitive in a landscape characterized by rapidly changing technologies and customer demands. Collaborations between established manufacturers and emerging tech firms are resulting in groundbreaking advancements that enhance efficiency, durability, and smart integration.

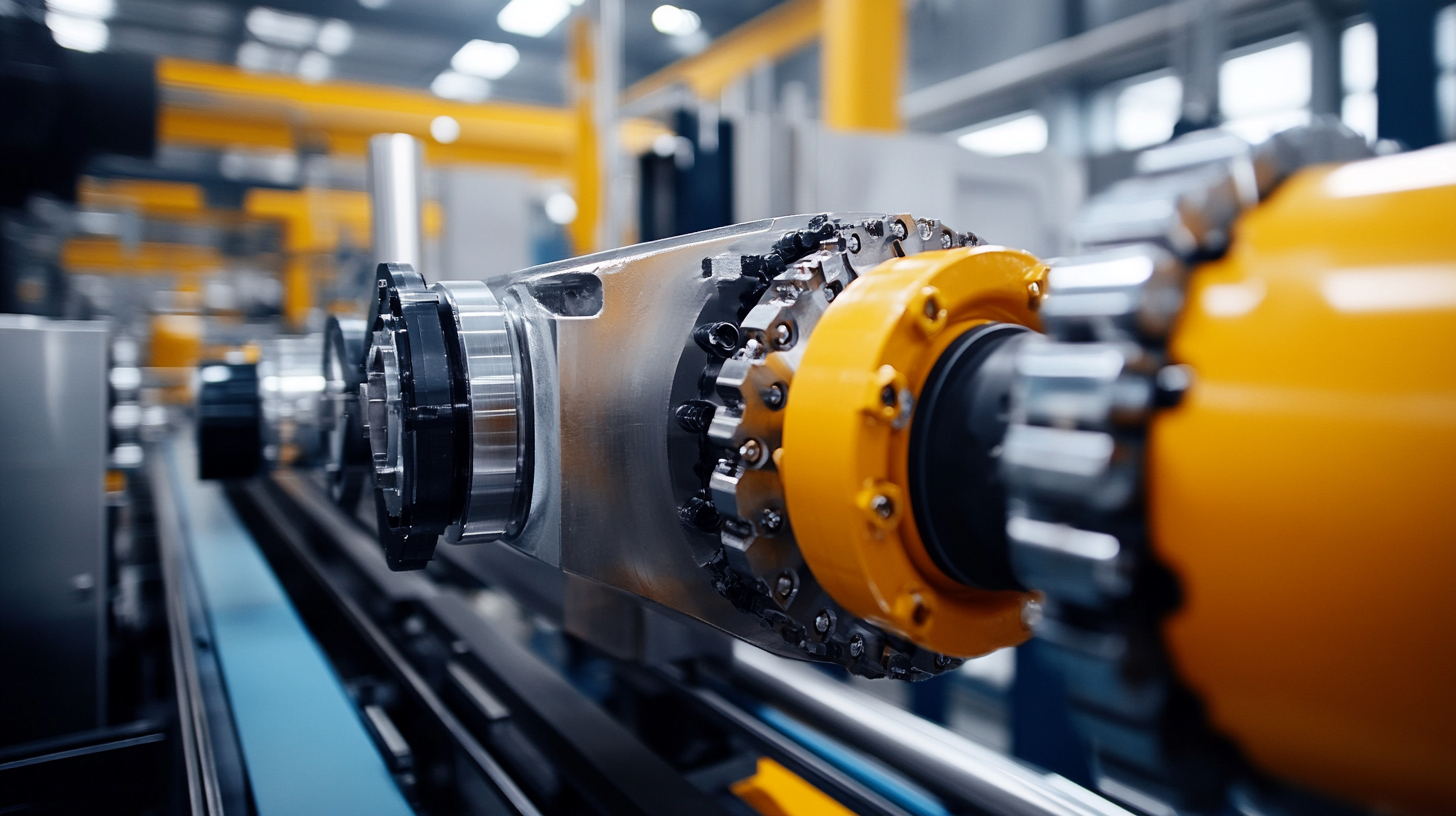

Significant competitors in the field are also focusing on strategic mergers and acquisitions to expand their technological capabilities and global outreach. By pooling resources, they not only improve their product offerings but also foster a culture of continuous innovation. The interplay between traditional hydraulic pump Engineering and cutting-edge digital technology is paving the way for smart hydraulic systems that are adaptive and energy-efficient. As these companies strive to meet the growing expectations of global buyers in 2025, the emphasis on collaborative innovation will be a defining factor in shaping the hydraulic pump industry's future.

Emerging markets are also influencing the competitive landscape, prompting companies to form regional partnerships that can help them navigate diverse regulatory environments and cultural preferences. By engaging local firms, global players can tap into invaluable insights and enhance customer relationships, which are vital for sustaining long-term growth. As the industry witnesses the fusion of technology and localized strategies, stakeholders must stay attuned to these evolving dynamics to capitalize on opportunities and outpace their competitors.