What is a Motorized Valve and How Does It Work?

In the world of industrial automation, the role of a Motorized Valve cannot be overstated. John Smith, a leading expert in fluid control systems, once stated, "Motorized valves are the backbone of automated systems." His insight reflects a truth that resonates with engineers and operators alike.

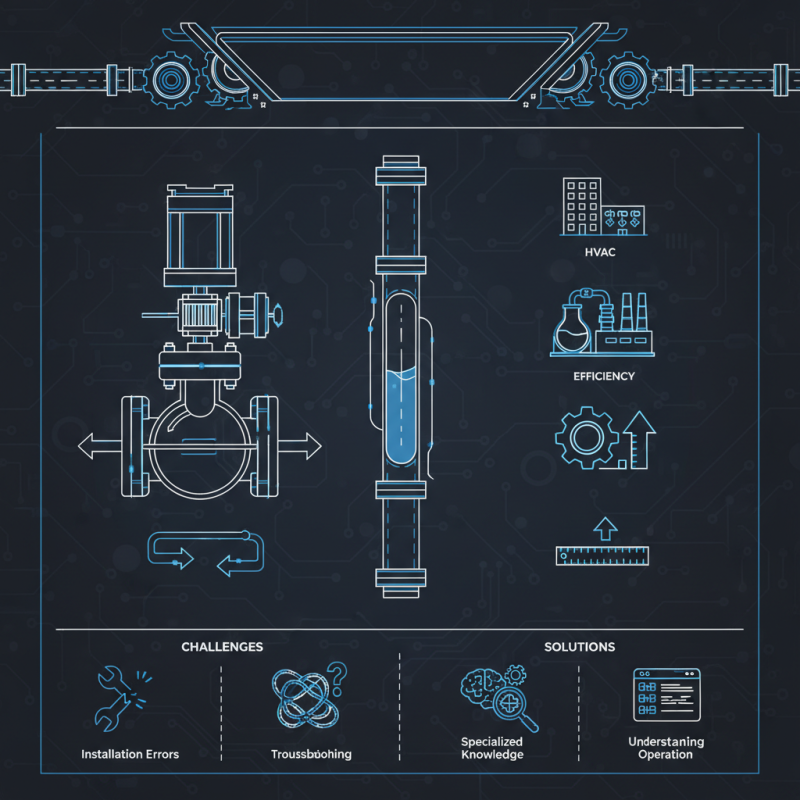

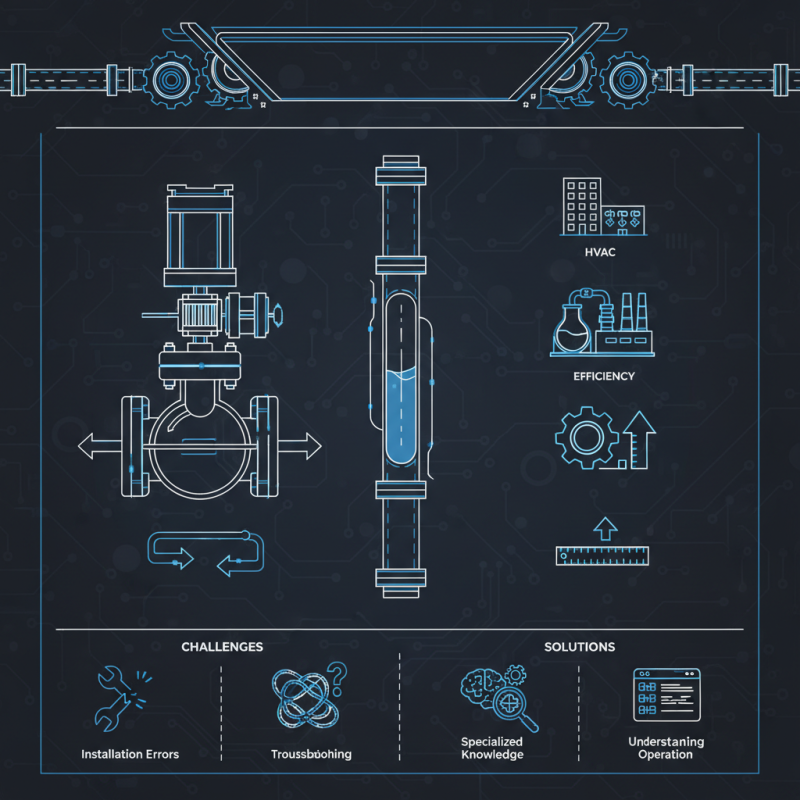

A motorized valve uses an actuator to control the flow of liquids or gases. These valves are indispensable in various applications, from HVAC systems to chemical processing plants. They help improve efficiency and enhance precision in operations. Yet, despite their benefits, challenges remain. For instance, installation errors can lead to significant issues. Troubleshooting these systems often requires specialized knowledge.

Understanding a motorized valve’s operation is vital for optimal performance. Familiarity with its components and functionality can prevent costly mistakes. As industries shift toward more automated solutions, grasping the intricacies of motorized valves becomes essential. This crucial learning journey may expose areas for improvement and contemplation.

Definition of a Motorized Valve and Its Components

A motorized valve is an essential component in many systems. It controls the flow of liquids or gases. This valve operates using a motor, which opens or closes it based on a signal. A motorized valve consists of several critical components. The most important include the valve body, actuator, and the control system.

The valve body is the main part that manages the flow. It can be made from different materials. Common options include brass and stainless steel. The actuator is the mechanism that moves the valve. It converts electrical signals into physical movement. The control system sends these signals based on operational needs.

Tips: Regular maintenance of motorized valves can extend their lifespan. Always check for signs of wear or leaks. Additionally, ensure that the electrical connections are secure to prevent malfunctions. If the valve is not responding, investigate the control signals. Sometimes, simple adjustments can solve major issues.

Types of Motorized Valves and Their Applications

Motorized valves play a crucial role in modern industrial applications. They help control the flow of fluids and gases in various systems. These valves are equipped with electric or pneumatic actuators, allowing for remote operation. They ensure accuracy and efficiency in processes, often replacing manual valve controls. Different types of motorized valves serve specific needs.

One common type is the globe valve, widely used for regulating flow. A study by the International Society of Automation reveals that flow control accounts for approximately 30% of operational costs in industrial settings. Quarter-turn valves, like ball valves, are popular for quick shut-off applications. Their simple mechanism allows faster response times. Another type is the butterfly valve, known for its compact design. It's favored in large pipes for its lightweight properties.

The application of motorized valves spans across industries. They are vital in HVAC systems, power plants, and water treatment facilities. However, the selection of the right valve type can be challenging. Miscalculations in size or type can lead to inefficiencies. Reports indicate almost 20% of valve installations fail to meet performance expectations. Careful planning is essential to mitigate these issues and leverage the full benefits of motorized valves.

Types of Motorized Valves and Their Applications

Mechanism of Operation for Motorized Valves

Motorized valves play a crucial role in various industries, controlling the flow of fluids based on electrical signals. These valves typically consist of a valve body, an actuator, and a control system. Understanding their mechanism of operation is essential for optimizing performance and efficiency.

The actuator is the core component that drives the motorized valve. When an electrical signal is received, the actuator rotates or moves linearly, adjusting the valve open or closed position. This movement can be precise, allowing for fine-tuned control. Reportedly, about 65% of industrial facilities have adopted some form of motorized control system, underscoring their significance in modern automation.

However, not all motorized valves operate flawlessly. Factors such as wear and tear, improper calibration, or environmental conditions can affect their performance. Industry studies indicate that maintenance issues contribute to a 15% increase in operational costs. Regular inspections and adherence to guidelines can mitigate some of these challenges, ensuring better reliability in fluid handling processes.

Advantages of Using Motorized Valves in Various Systems

Motorized valves offer numerous advantages for various systems, enhancing efficiency and control. These devices automate the flow of liquids and gases in pipelines. They can be found in heating, ventilation, and air conditioning systems. Their precision allows for optimal performance and energy savings.

One significant benefit is automation. This means less manual work is needed. Engineers and operators appreciate the reduced strain. With motorized valves, the risk of human error decreases. They can operate on schedules or respond to changes swiftly. This adaptability is crucial in many industries.

On the downside, motorized valves are not without challenges. They require a power source, which may be a limitation. Maintenance can be complicated as well. Sometimes, simple mechanical valves may suffice. Users should carefully assess their unique situations. With thoughtful consideration, the benefits often outweigh potential drawbacks.

Common Issues and Maintenance Tips for Motorized Valves

Motorized valves are essential in many systems. They control the flow of liquids or gases automatically. However, these devices often encounter issues that can affect performance. Common problems include electrical failures or valve jamming. Both situations can stop the valve from responding as it should. Regular checks are crucial. It can help identify potential problems early on.

Maintenance allows for smoother operation. Keep the area around the valve clean and clear of debris. Dust and dirt can accumulate, leading to malfunctions. Inspect electrical connections regularly. Loose wires can create shorts or signal failure. Perform routine checks to ensure the valve opens and closes properly. It takes only a few minutes but can save time and money down the road.

Lastly, consider the environment. High temperatures or extreme humidity can create unseen challenges. Proper insulation or covers may be necessary. If a valve frequently malfunctions, rethink the selection or placement. Frustration arises when issues persist, leaving you questioning choices. Recording maintenance activities can highlight patterns. Documenting issues often leads to better decision-making.

What is a Motorized Valve and How Does It Work? - Common Issues and Maintenance Tips for Motorized Valves

| Dimension | Description | Common Issues | Maintenance Tips |

| Type | Electric, Pneumatic, Hydraulic | Sticking, Leakage | Regularly check for signs of wear |

| Voltage | 24V, 120V, 230V | Power Failure | Ensure proper electrical connections |

| Material | Brass, Stainless Steel, Plastic | Corrosion, Damage | Inspect for corrosion regularly |

| Control Method | Manual, Automatic | Calibration Issues | Calibrate the system annually |

| Applications | Heating, Cooling, Water Supply | Incompatibility Issues | Match valves with the application |