Essential Insights for Optimizing Tractor Hydraulic Pump Performance

The performance of a Tractor Hydraulic Pump is pivotal to the overall efficiency and productivity of agricultural operations. According to a recent report by the Agricultural Machinery Manufacturers Association (AMMA), hydraulic systems account for approximately 30% of a tractor's operational efficiency, underscoring the importance of understanding and optimizing these components. As agricultural practices continue to evolve, driven by advancements in technology and increased demands for crop yield, the need for efficient hydraulic systems has never been more critical. Optimizing hydraulic pump performance not only enhances tractor functionality but also reduces downtime, leading to significant cost savings.

Industry insights suggest that ensuring optimal hydraulic pump performance can increase equipment lifespan by up to 20% and improve fuel efficiency by about 15%, based on data from the Precision Agriculture Institute. In a landscape where every percentage point counts, farmers and equipment operators must harness techniques and knowledge to enhance the role of the Tractor Hydraulic Pump within their machinery. This blog aims to provide essential insights and strategies for optimizing hydraulic pump performance, contributing to more sustainable and productive agricultural practices.

Understanding the Role of Hydraulic Pumps in Tractor Performance

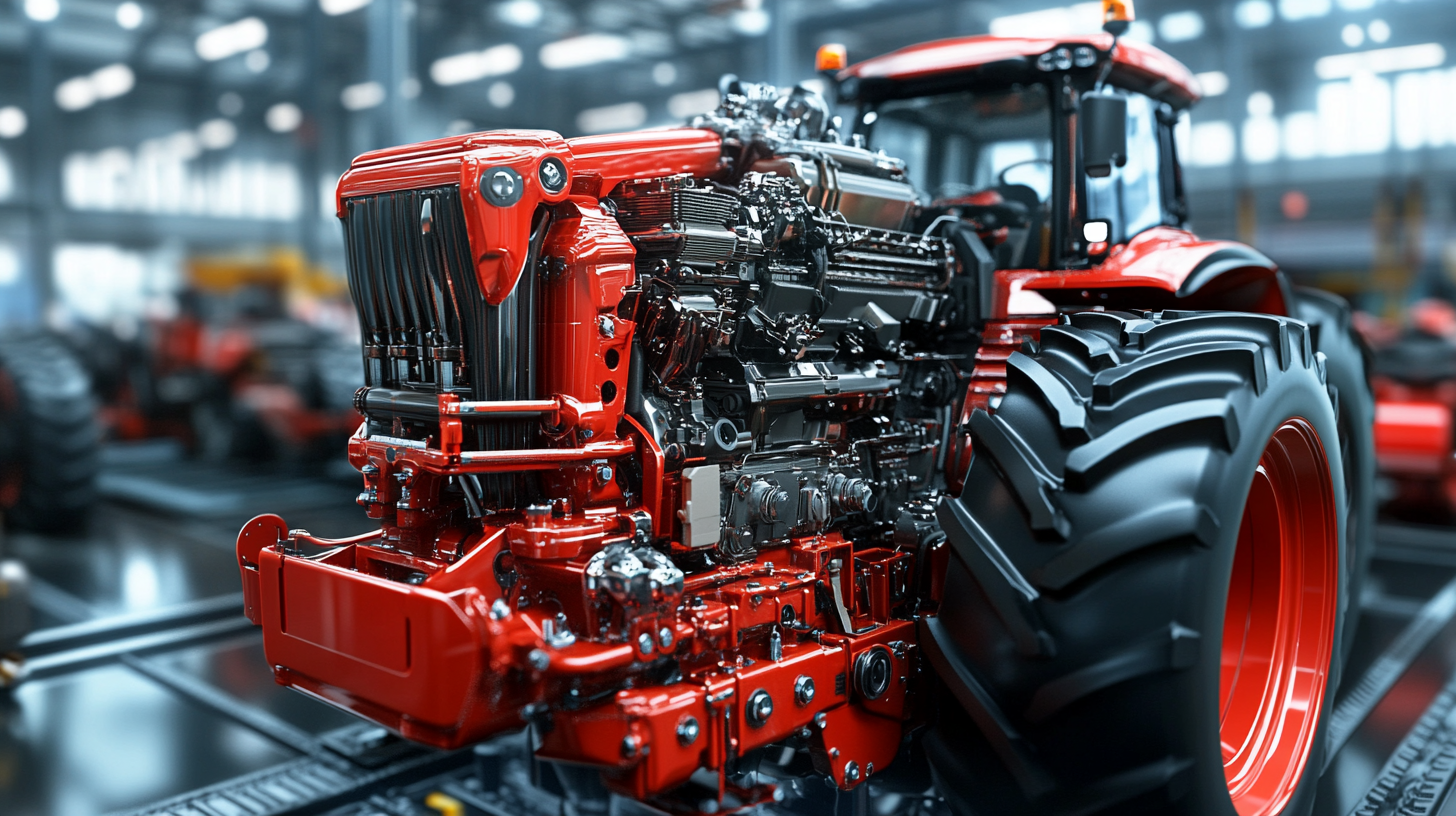

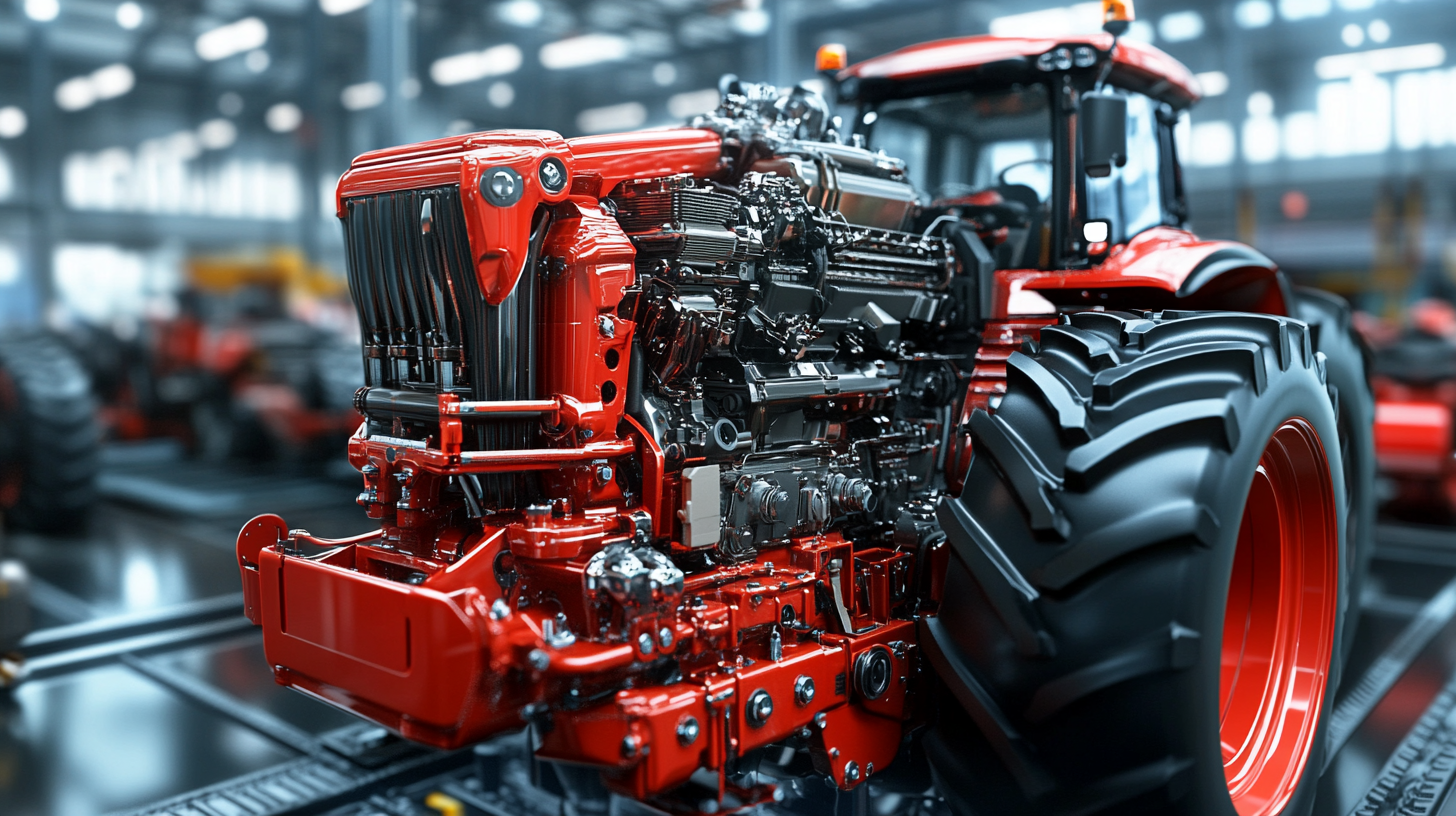

Hydraulic pumps play a crucial role in maximizing tractor performance by facilitating efficient power transmission and enhancing operational capabilities. In modern agricultural machinery, advancements in hydraulic systems have led to significant improvements in torque and flow capacities. For instance, the latest series of tractors have integrated optimized hydraulic designs that deliver improved efficiency and productivity. According to industry reports, these advanced hydraulic systems can increase machine performance by up to 20%, showcasing the importance of hydraulic pump optimization in farming equipment.

Temperature and pressure sensing are critical factors that directly influence the performance and safety of hydraulic pumps in tractors. Accurate monitoring ensures that hydraulic systems operate within optimal ranges, preventing overheating and potential failures. Reports indicate that systems equipped with real-time data sensing can enhance operational reliability, significantly reducing maintenance costs by up to 30%. By integrating these technologies, manufacturers can provide farmers with tools that not only boost productivity but also ensure sustainable practices.

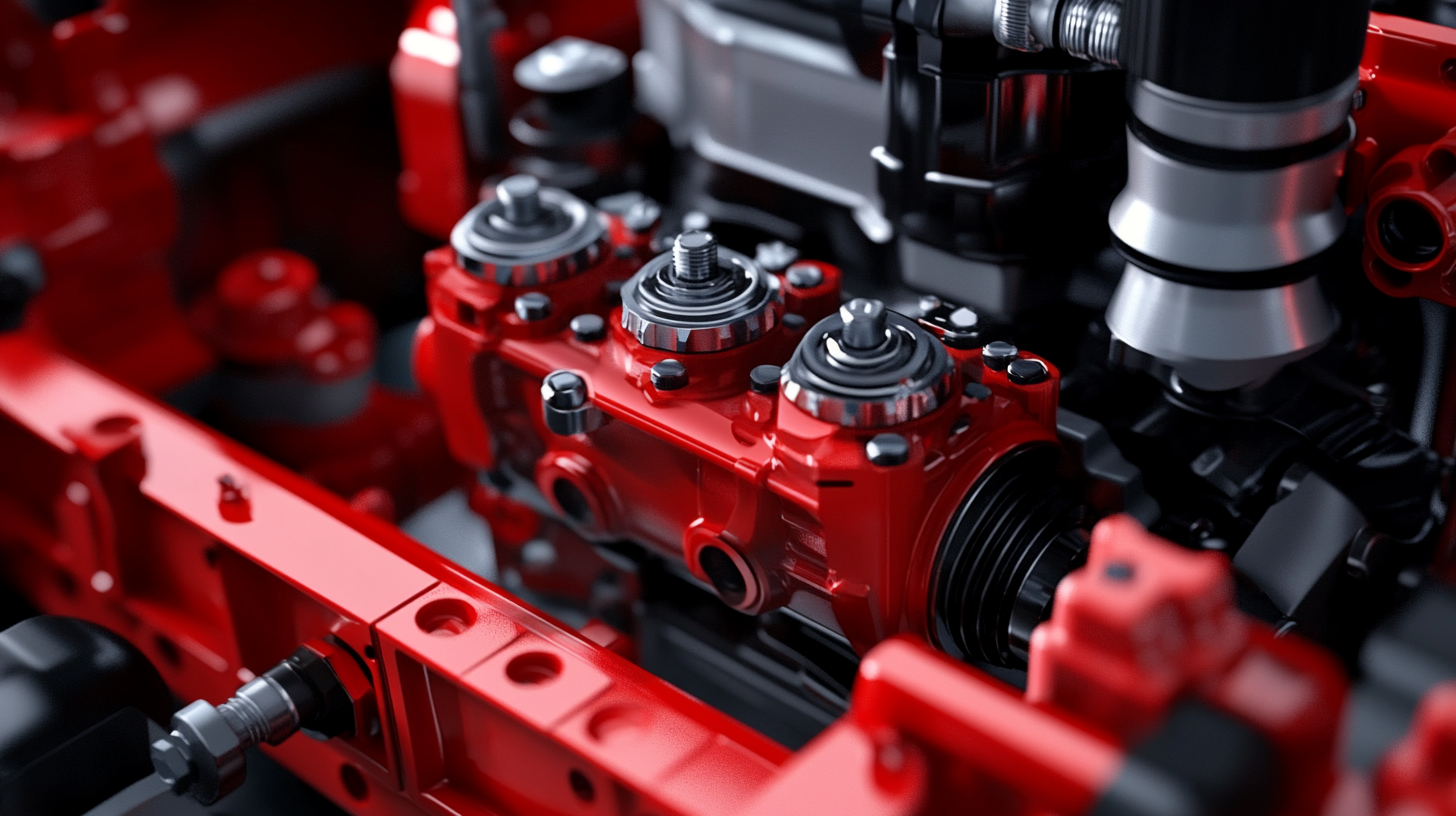

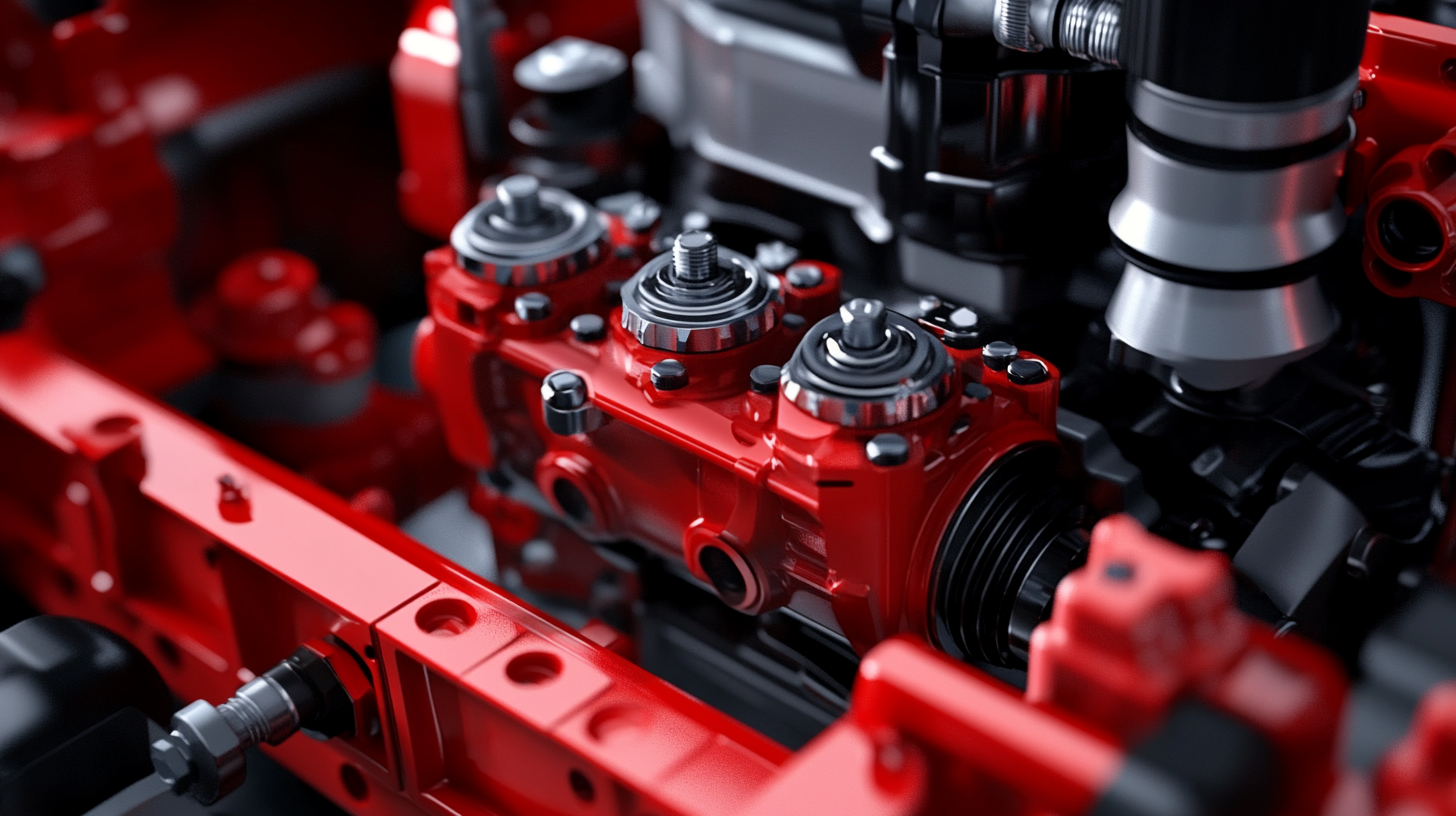

The structure and design of hydraulic piston pumps have evolved to meet the demands of modern agricultural tasks. With continuous improvements, these pumps now feature enhanced valve plates and swash plates that contribute to higher efficiency and reduced energy consumption. As tractors face increasingly complex farming conditions, leveraging these advanced hydraulic systems becomes essential for achieving better fuel efficiency and overall productivity. Industry insights suggest that the integration of cutting-edge hydraulic components will continue to shape the future of agricultural machinery.

Key Factors Affecting Hydraulic Pump Efficiency

Optimizing the efficiency of hydraulic pumps is crucial for achieving peak performance in tractor applications. Several key factors significantly influence hydraulic pump efficiency, making it essential for operators and manufacturers alike to understand these elements. Proper maintenance and timely servicing are among the most critical aspects; regular checks for leaks and wear can prevent performance degradation over time. Additionally, understanding the specific needs of different agricultural tasks helps in selecting the right pump and configuration, which can lead to enhanced efficiency and reduced fuel consumption.

Another vital factor impacting hydraulic pump performance is the quality and viscosity of the hydraulic fluid used. A fluid that meets the manufacturer's specifications ensures optimal lubrication and reduces wear on pump components. Furthermore, as the hydraulic gear pump market is expected to reach $12.6 billion by 2032, stakeholders must innovate and adopt advanced technologies to improve the design and functionality of these pumps. Emphasizing the development of more efficient hydraulic systems will not only enhance tractor performance but also contribute to sustainable agricultural practices by minimizing energy usage and operational costs.

As the demand for efficient hydraulic solutions grows, it is imperative that farmers and equipment operators stay informed about the latest advancements and best practices in hydraulic pump technology. Embracing new methodologies, such as real-time monitoring systems and predictive maintenance strategies, can lead to more reliable equipment and better overall productivity in the field.

Best Practices for Maintaining Hydraulic Pump Health

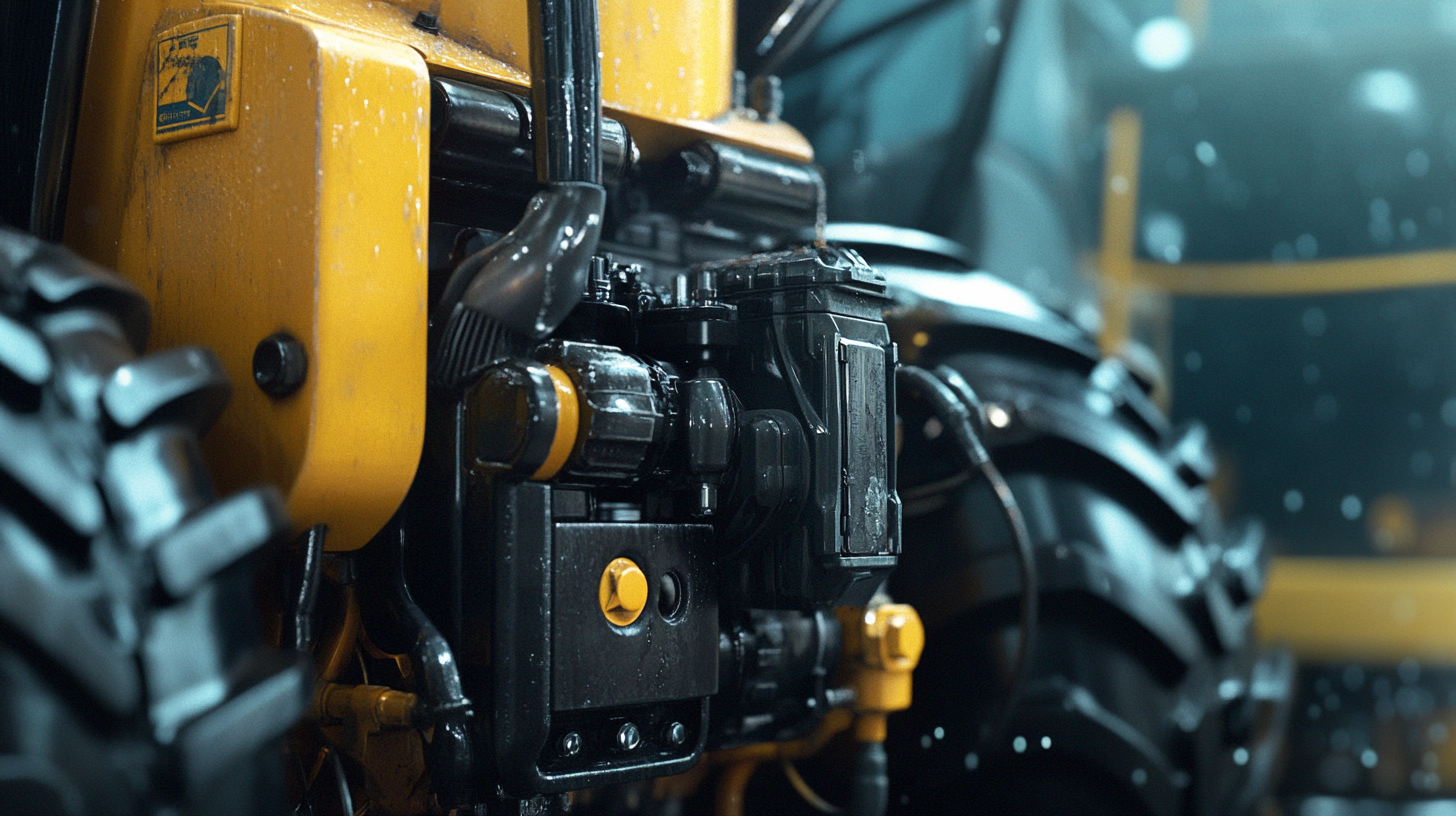

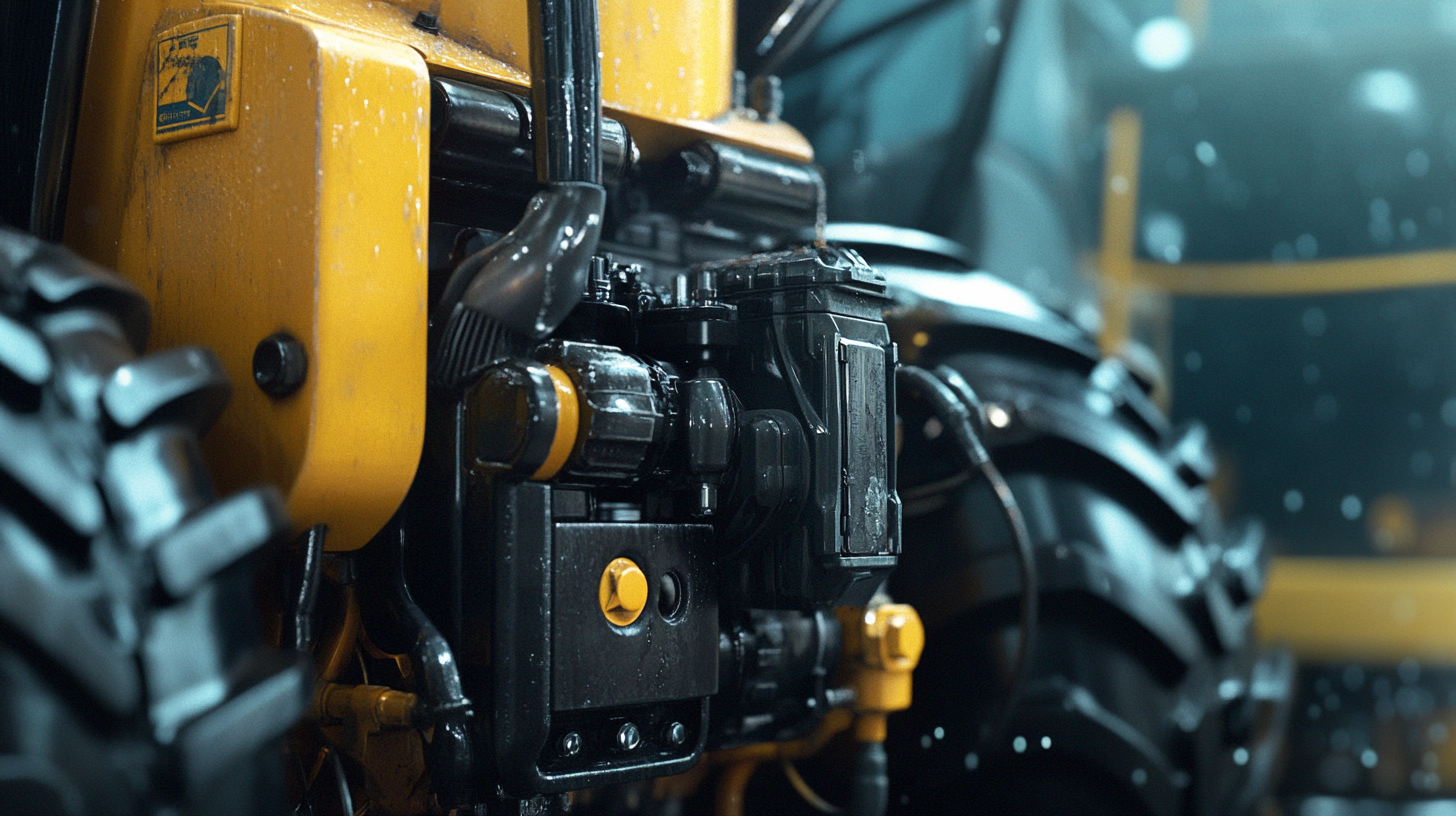

Hydraulic pumps are essential components in tractor systems, enabling efficient operation in various agricultural and industrial applications. To maintain the health of these hydraulic systems, implementing best practices for hydraulic pump maintenance is crucial. One of the key aspects of this maintenance is condition monitoring, which uses advanced technologies, including IoT, to continually assess the status of hydraulic components. By monitoring performance metrics and potential failures, operators can take proactive measures to avoid severe breakdowns and ensure optimal pump functionality.

In addition to condition monitoring, regular inspections and maintenance routines play a vital role in keeping hydraulic pumps in top shape. Operators should focus on checking the integrity of hydraulic fluids, ensuring they are free from contamination, which can jeopardize pump performance. Furthermore, addressing wear and tear in critical components like filters and mesh screens will prevent obstructive debris from damaging the system. Awareness of common risks, such as hydraulic-injection injuries, is also essential for maintaining a safe working environment, as these injuries can occur if proper precautions are not taken during maintenance tasks.

Finally, training for personnel on the correct handling and maintenance of hydraulic systems can further enhance performance and longevity. By fostering a culture of safety and best practices, organizations not only protect their hydraulic investments but also promote a healthier work environment. Through diligence in maintenance and focusing on health optimizations, the reliability and efficiency of tractor hydraulic pumps can be significantly improved.

Troubleshooting Common Hydraulic Pump Issues in Tractors

When dealing with hydraulic pumps in tractors, understanding and troubleshooting common issues can significantly enhance their performance. One of the most prevalent problems is inadequate hydraulic flow, which can lead to sluggish operation. This may be caused by a variety of factors, including a clogged filter or improper fluid levels. Regularly checking and replacing filters, alongside ensuring that the hydraulic fluid is at the correct level and viscosity, can help prevent these issues.

Another common issue is inconsistent or erratic operation of the hydraulic system. This can often be traced back to air entering the system, which can disrupt the flow of hydraulic fluid. To address this, it is essential to inspect the hydraulic lines and connections for leaks. Additionally, bleeding the system to eliminate any trapped air can restore smooth operation. Keeping the hydraulic system well-maintained and regularly inspecting the components can help diagnose these issues before they escalate.

Lastly, worn or damaged hydraulic pump components can significantly affect performance. Signs of wear include unusual noises or vibrations during operation. It is crucial to conduct routine maintenance checks to identify and replace any worn parts, such as seals or bearings, before they lead to more extensive damage. Staying proactive with maintenance can ensure the hydraulic system operates efficiently, enhancing overall tractor performance and reliability.

Upgrading and Retrofitting Hydraulic Systems for Improved Performance

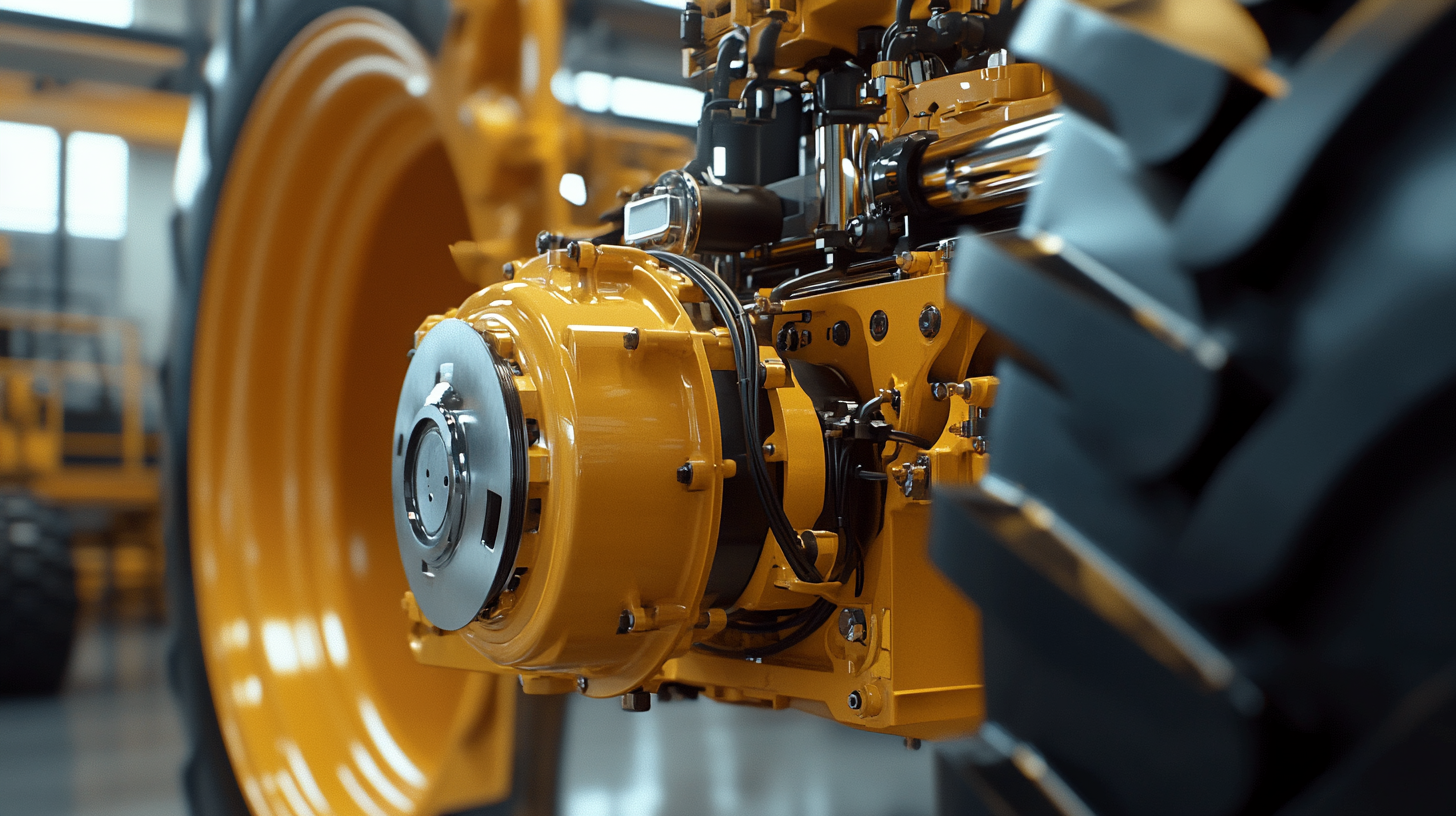

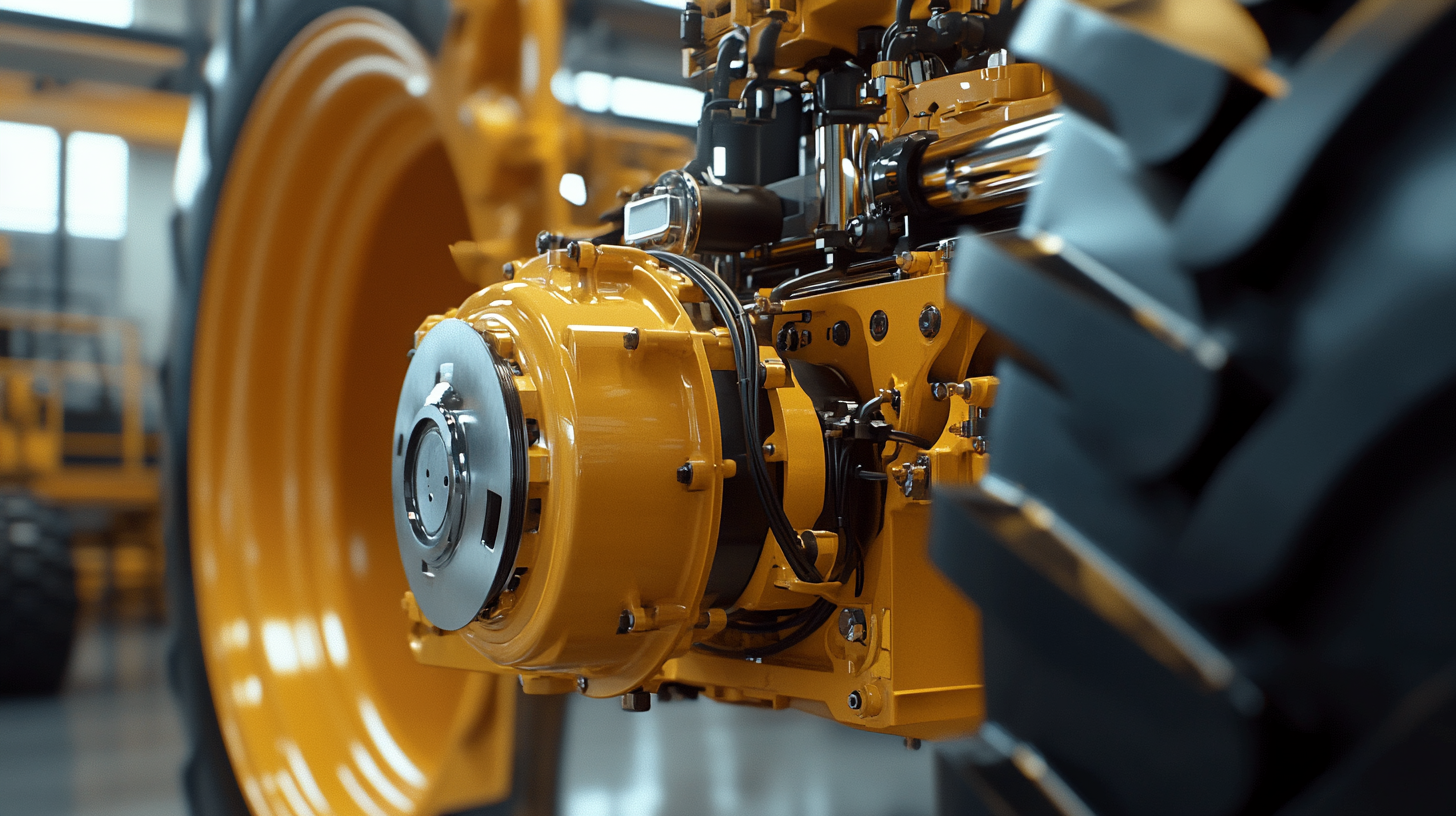

Optimizing hydraulic systems in tractors can significantly enhance their performance, especially when considering the options for upgrading and retrofitting existing setups. Upgrading hydraulic components can lead to efficiencies that not only maximize output but also extend the equipment's lifespan. Modern hydraulic power units offer improved design metrics that stand in sharp contrast to their conventional counterparts. By focusing on crucial areas such as fluid dynamics and component compatibility, engineers can carefully select retrofit kits that will rapidly elevate a tractor's operational capabilities.

For instance, recent advancements suggest that integrating accumulators into hydraulic systems can greatly enhance performance, as demonstrated in various large-scale projects, such as refurbishing significant infrastructures. Similarly, aftermarket kits designed for older models can revitalize equipment by replacing outdated components with state-of-the-art technology. With the right upgrades, these retrofitted systems can achieve a level of reliability and power efficiency that meets contemporary operational demands.

Moreover, the trend towards automation and energy-efficient systems in fluid power equipment reflects a broader market growth, projected at a steady CAGR over the coming years. By investing in these upgrades, tractor operators not only streamline their current activities but also future-proof their operations, ensuring they remain competitive in an ever-evolving agricultural landscape. The benefits of retrofitting extend beyond immediate performance gains, making them a valuable consideration for anyone looking to improve their hydraulic system's efficiency.