Overcoming Challenges with Best Hydraulic Pump Efficiency and Reliability

In the dynamic landscape of hydraulic systems, the efficiency and reliability of hydraulic pumps remain pivotal for industrial operations. As we approach 2025, industry reports project a significant growth rate, with the global hydraulic pumps market expected to reach approximately $12 billion by that year, expanding at a CAGR of over 5%. This growth underscores the increasing demand for high-performing hydraulic pumps, which are vital for enhancing system productivity while minimizing energy consumption. Furthermore, advancements in technology are enabling manufacturers to innovate and improve the lifecycle and performance metrics of these essential components. Addressing the challenges of maximizing hydraulic pump efficiency not only leads to substantial cost savings but also contributes to sustainable practices within the industry. As such, it is imperative to explore the best types of hydraulic pumps and their reliability to meet the evolving demands of modern applications.

In the dynamic landscape of hydraulic systems, the efficiency and reliability of hydraulic pumps remain pivotal for industrial operations. As we approach 2025, industry reports project a significant growth rate, with the global hydraulic pumps market expected to reach approximately $12 billion by that year, expanding at a CAGR of over 5%. This growth underscores the increasing demand for high-performing hydraulic pumps, which are vital for enhancing system productivity while minimizing energy consumption. Furthermore, advancements in technology are enabling manufacturers to innovate and improve the lifecycle and performance metrics of these essential components. Addressing the challenges of maximizing hydraulic pump efficiency not only leads to substantial cost savings but also contributes to sustainable practices within the industry. As such, it is imperative to explore the best types of hydraulic pumps and their reliability to meet the evolving demands of modern applications.

Understanding the Importance of Hydraulic Pump Efficiency in Industrial Applications

Hydraulic pumps play a crucial role in industrial applications, where efficiency can significantly impact overall operations. Understanding the importance of hydraulic pump efficiency is essential for maximizing productivity and reducing operational costs. High-efficiency hydraulic pumps not only consume less energy but also reduce the wear and tear on components, leading to lower maintenance expenses and longer service life. This is particularly vital in industries that rely on heavy machinery, where even minor inefficiencies can result in substantial downtime and loss of revenue.

Incorporating advanced technology and regularly maintaining hydraulic systems can enhance pump reliability and performance. Businesses that prioritize the selection of efficient hydraulic pumps are better equipped to handle fluctuating demands and operational challenges. By focusing on hydraulic pump efficiency, industries can improve their environmental footprint, as reduced energy consumption directly correlates with lower emissions. Thus, investing in high-quality, efficient hydraulic pumps is not only a strategic business decision but also a step toward sustainable industrial practices.

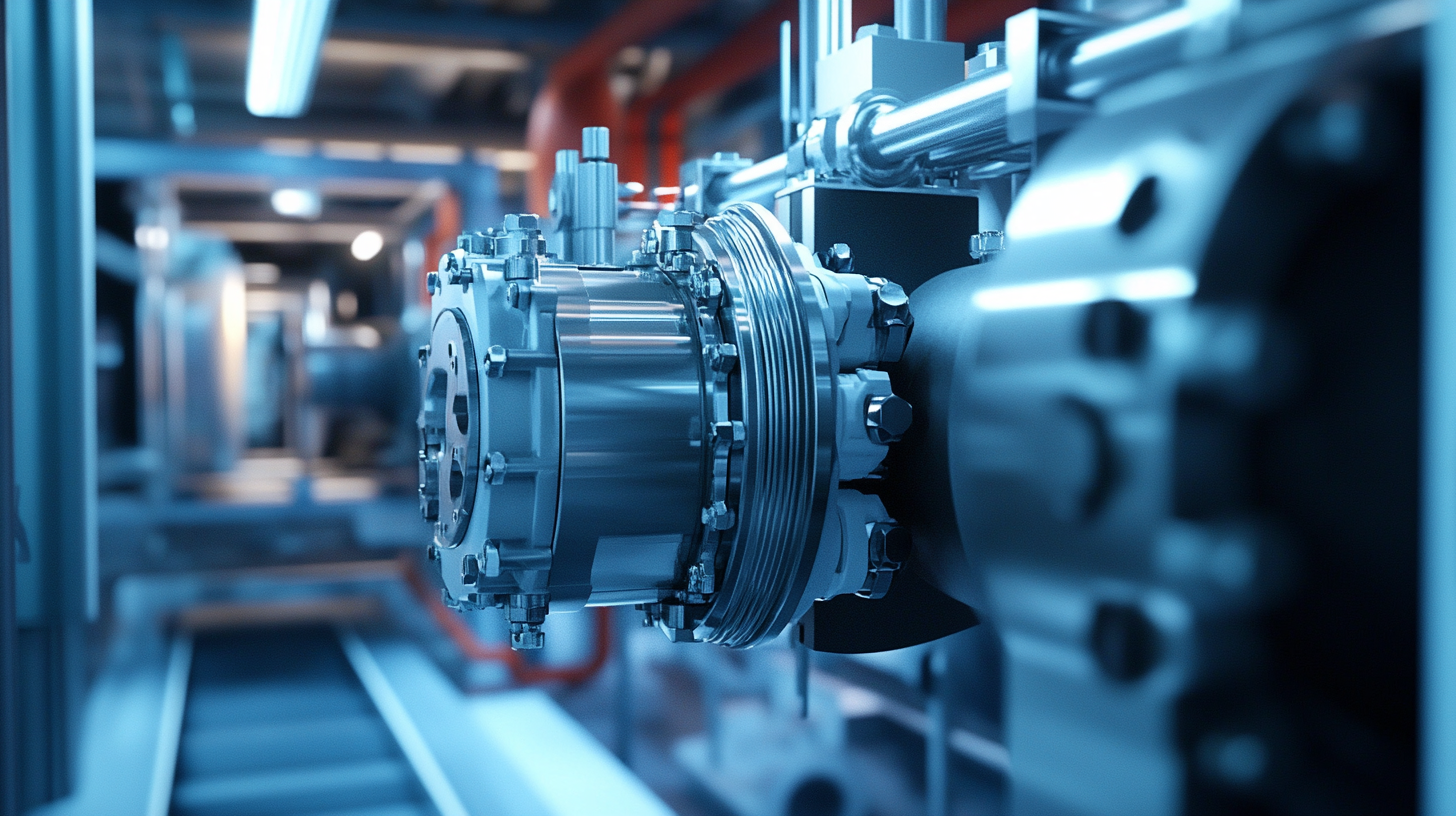

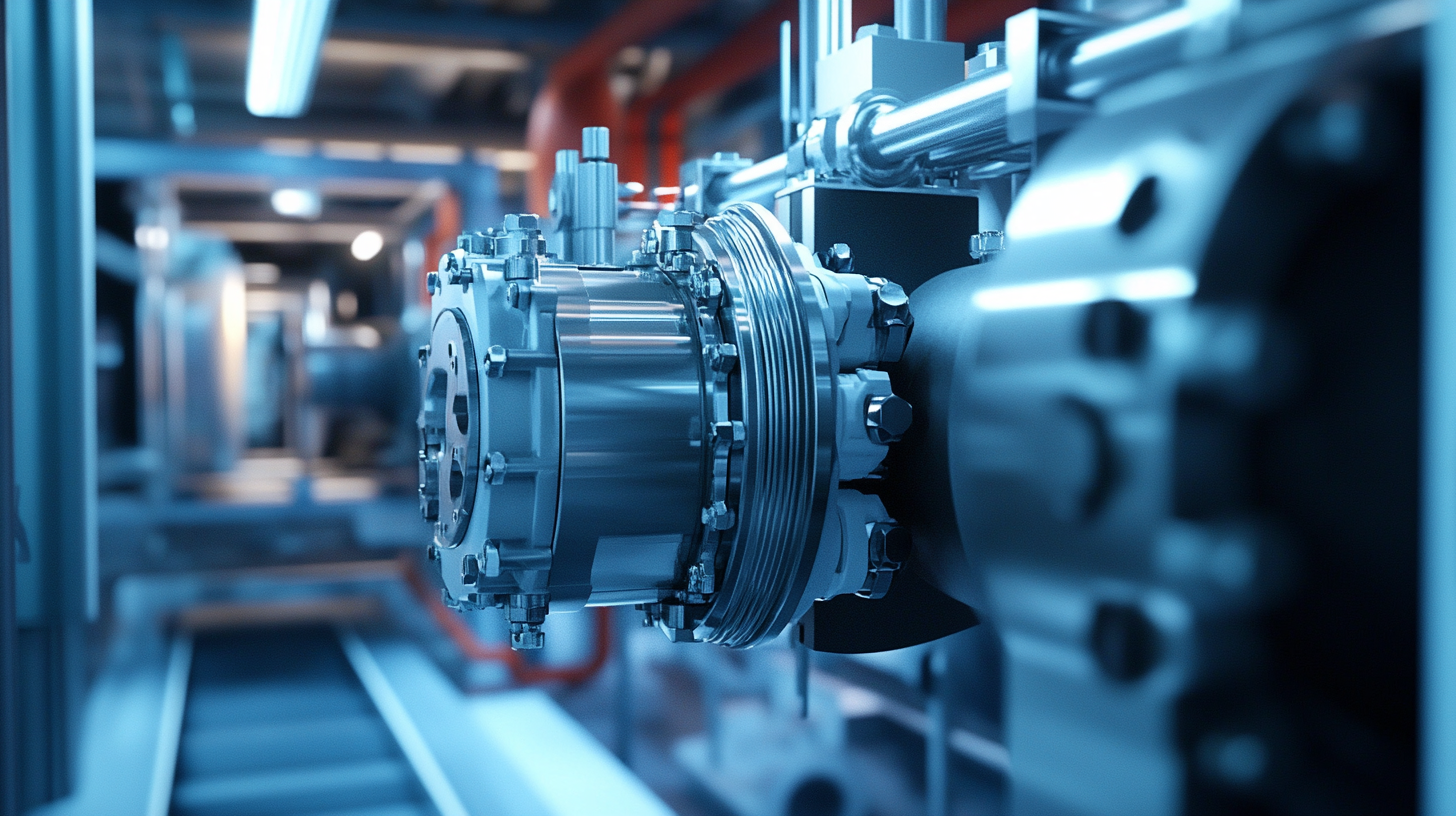

Hydraulic Pump Efficiency in Industrial Applications

Key Factors Influencing Hydraulic Pump Reliability and Performance

Hydraulic pumps play a crucial role in various industries, and their reliability and performance are influenced by several key factors. First and foremost, the design and materials used in the pump construction significantly affect its durability and efficiency. High-quality materials can resist wear and fatigue, ensuring a longer lifespan and lowering maintenance costs. Additionally, precise engineering in pump design can minimize internal losses, which enhances overall efficiency and responsiveness in hydraulic systems.

Another important factor is regular maintenance and adherence to operating guidelines. Routine checks on fluid levels, contamination, and wear parts are essential for preserving pump functionality. Hydraulic fluid quality is also vital, as inferior fluids can lead to increased friction and degradation, ultimately affecting pump performance. Furthermore, system compatibility and proper installation play critical roles; mismatched components can lead to leaks and inefficiencies. By addressing these factors, organizations can significantly improve the reliability and efficiency of their hydraulic pumps, maximizing productivity and reducing downtime.

Industry Standards and Best Practices for Hydraulic Pump Maintenance

Hydraulic pumps are integral to numerous industrial applications, yet their efficiency and reliability can be significantly impacted by maintenance practices. According to a report by the Hydraulics Institute, up to 30% of pump failures can be attributed to poor maintenance, leading to costly downtimes and reduced productivity.

Implementing industry standards, such as the ISO 9001 quality management system, can enhance maintenance procedures by ensuring routine inspections and adherence to best practices. These standards provide a framework that emphasizes consistency and documentation, essential for tracking performance metrics and identifying potential issues before they escalate.

Best practices in hydraulic pump maintenance also include regular oil analysis, which can help in detecting contaminants and wear particles. A study by the National Center for Manufacturing Sciences reveals that companies conducting regular oil analysis can extend the life of their hydraulic pumps by up to 50%. Additionally, following the manufacturer's guidelines for operating conditions and maintenance schedules ensures that pumps operate within optimal parameters. By prioritizing these practices, industries can not only overcome challenges associated with hydraulic pump performance but also foster a culture of continuous improvement, ultimately leading to enhanced operational efficiency and reliability.

Innovative Technologies to Enhance Hydraulic Pump Efficiency

Innovative technologies in hydraulic pump systems play a crucial role in significantly enhancing efficiency and reliability, addressing the challenges of modern industrial applications. Recent studies indicate that the adoption of advanced materials and design methodologies can improve pump efficiency by up to 15%. For instance, the integration of computational fluid dynamics in hydraulic design allows engineers to optimize the flow characteristics within the pump, reducing cavitation and erosion and extending the equipment’s lifespan while ensuring peak performance.

Moreover, digitalization and IoT technologies are revolutionizing hydraulic systems by enabling real-time monitoring and predictive maintenance. A report by the Hydraulic Institute suggests that companies implementing these technologies can reduce unplanned downtime by 20% or more. By leveraging data analytics, operators can anticipate pump failures before they occur, minimizing costly interruptions and improving overall system reliability. This shift towards smart hydraulic systems not only enhances operational efficiency but also drives sustainable practices in the industry by lowering energy consumption and reducing waste.

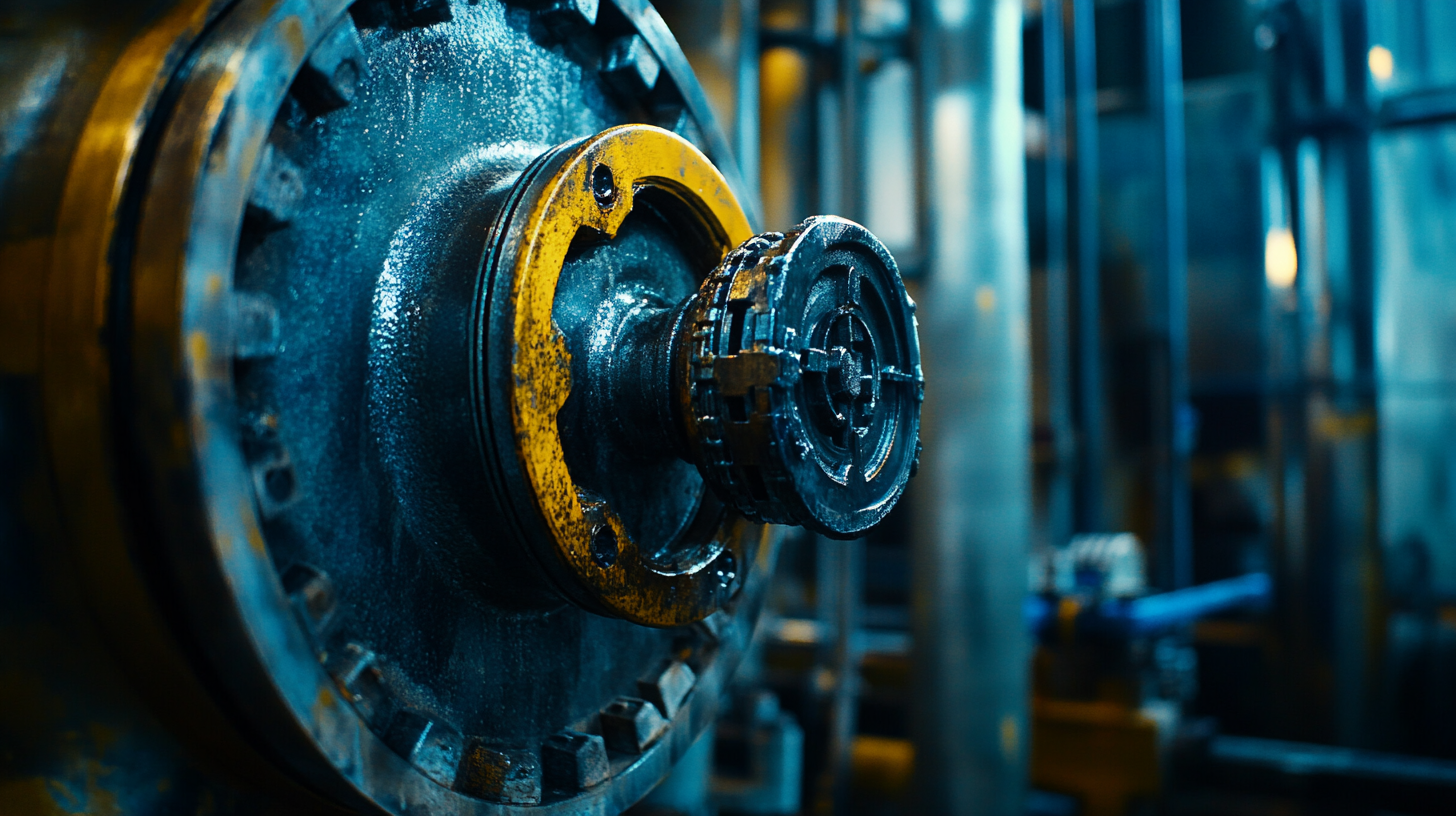

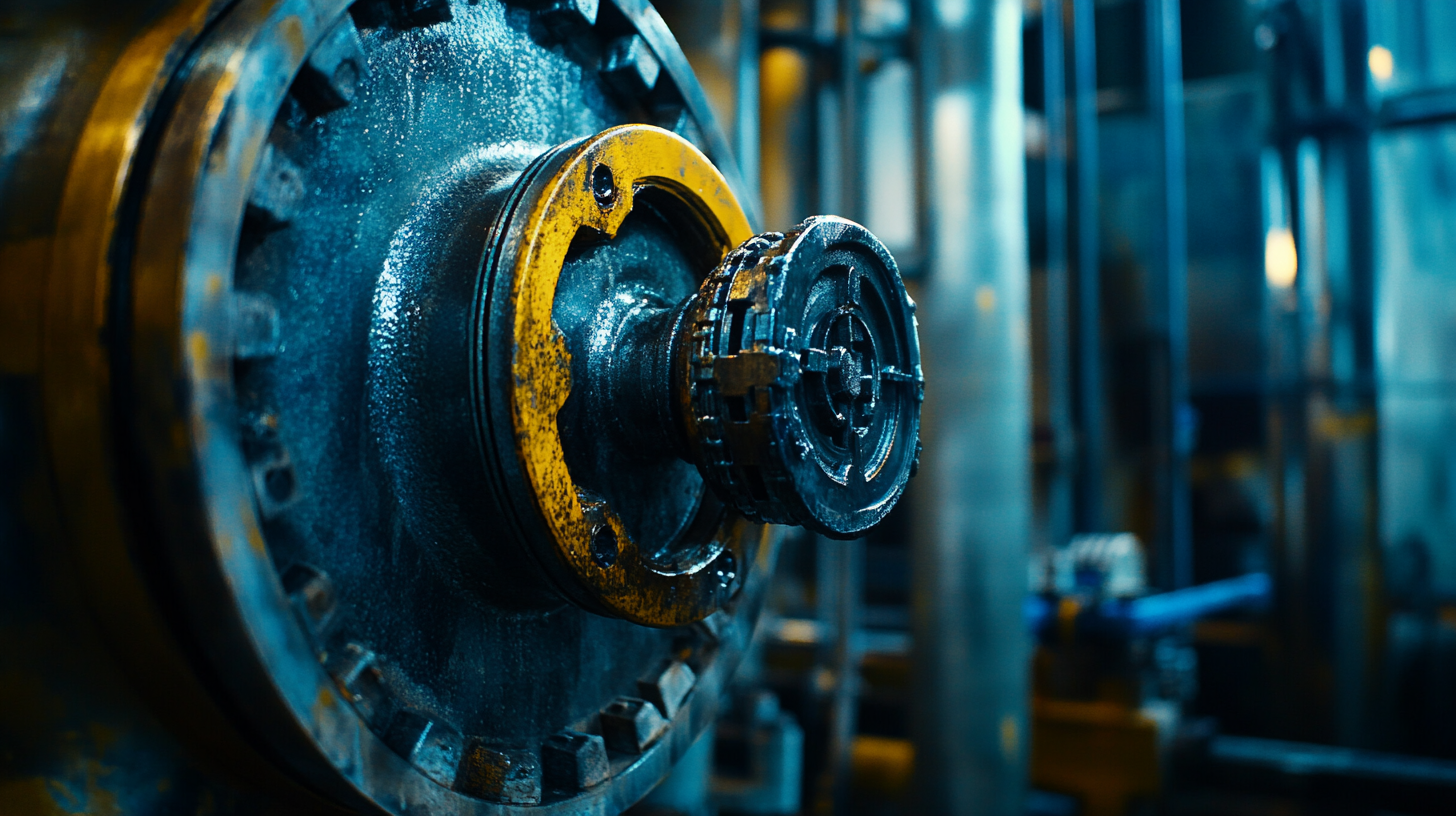

Overcoming Challenges with Best Hydraulic Pump Efficiency and Reliability - Innovative Technologies to Enhance Hydraulic Pump Efficiency

| Technology |

Description |

Efficiency Gain (%) |

Reliability Increase (%) |

Implementation Cost ($) |

| Variable Displacement Pumps |

Adjusts flow based on demand, improving efficiency |

20 |

15 |

2500 |

| Hybrid Pump Systems |

Combines electric and hydraulic for optimal performance |

25 |

20 |

4000 |

| Smart Sensors |

Monitors pump performance and optimizes efficiency |

10 |

30 |

1500 |

| Advanced Filtration |

Eliminates contaminants to prolong equipment life |

15 |

25 |

2000 |

| Digital Control Systems |

Automates pump operations for peak efficiency |

30 |

35 |

5000 |

Real-World Case Studies: Overcoming Operational Challenges with Efficient Hydraulics

In today’s industrial landscape, maximizing hydraulic pump efficiency is crucial for overcoming operational challenges. Real-world case studies reveal that companies can achieve up to 30% lower energy consumption by implementing advanced hydraulic systems, as supported by the Hydraulic Institute's latest report. For instance, a leading construction firm upgraded its hydraulic pumps and saw a significant reduction in downtime, solidifying the importance of reliable hydraulic solutions in demanding environments.

To enhance hydraulic pump performance, it's vital to consider a few practical tips. First, regular maintenance is essential; according to the Machinery Lubrication journal, routine fluid analysis can extend pump life by approximately 25%. Additionally, investing in modern pump technology with variable speed drives can optimize energy efficiency, allowing operations to adapt to varying load conditions seamlessly.

Another key factor is operator training. Research shows that informed operators can reduce operational errors by up to 40%, dramatically improving system reliability. Empowering team members with knowledge about hydraulic systems can lead to better troubleshooting and quicker resolutions to unexpected issues, ensuring that the hydraulic equipment runs at peak efficiency.

In the dynamic landscape of hydraulic systems, the efficiency and reliability of hydraulic pumps remain pivotal for industrial operations. As we approach

In the dynamic landscape of hydraulic systems, the efficiency and reliability of hydraulic pumps remain pivotal for industrial operations. As we approach