Exploring Quality Alternatives to Hydraulic Pump Options for Global Buyers

In a world where the demand for efficient machinery and robust hydraulic systems continues to rise, exploring quality alternatives to traditional hydraulic pump options is more critical than ever for global buyers. The diverse range of hydraulic pump types and technologies available can overwhelm decision-makers, making it essential to navigate through the options effectively. Our comprehensive Hydraulic Pump Catalog serves as a valuable resource, showcasing not only the conventional hydraulic pumps but also innovative alternatives that offer unique benefits. These alternatives can enhance operational efficiency, reduce energy consumption, and lower maintenance costs, making them attractive options for industries striving for sustainability and performance. This blog aims to delve into the myriad benefits of various hydraulic pump types, empowering buyers to make informed decisions that align with their operational needs and long-term goals.

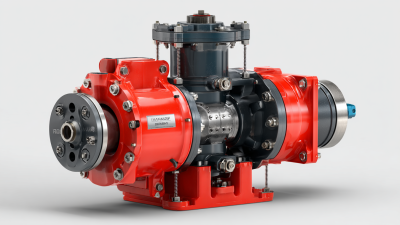

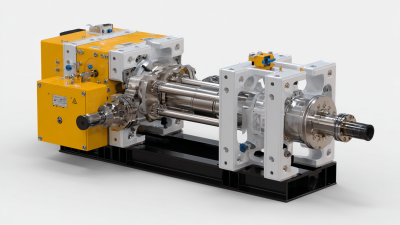

Innovative Technologies Revolutionizing Hydraulic Pump Alternatives

As industries evolve, so do the technologies that support their hydraulic systems. Innovative alternatives to traditional hydraulic pumps are emerging, driven by advances in engineering and materials science. These alternatives not only enhance efficiency but also address environmental concerns by reducing energy consumption and emissions. Electric actuators and pneumatic systems are at the forefront, offering remarkable precision and responsiveness compared to conventional hydraulic pumps while minimizing contamination risks.

Furthermore, the integration of smart technology in hydraulic alternatives is transforming operational dynamics. IoT-enabled sensors and machine learning algorithms allow for real-time performance monitoring and predictive maintenance, optimizing functionality and extending equipment lifespan. Users can now benefit from systems that are not only easier to install and maintain but also adaptable to various operational demands. The shift towards these innovative solutions signals a significant transformation in how global buyers approach their hydraulic needs, emphasizing sustainability and efficiency in their selection process.

Exploring Quality Alternatives to Hydraulic Pump Options for Global Buyers - Innovative Technologies Revolutionizing Hydraulic Pump Alternatives

| Alternative Technology |

Efficiency (%) |

Cost (USD) |

Maintenance Frequency (months) |

Sustainability Rating (1-5) |

| Electric Motors |

90 |

800 |

24 |

5 |

| Pneumatic Pumps |

85 |

600 |

18 |

4 |

| Servo Systems |

92 |

1500 |

30 |

5 |

| Magnetic Drive Pumps |

87 |

950 |

36 |

3 |

| Hydraulic Accumulators |

88 |

700 |

12 |

4 |

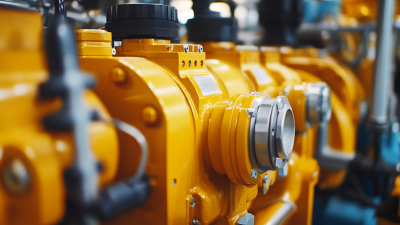

Sustainable Solutions: Eco-Friendly Hydraulic Pump Options

In recent years, the push for sustainability has permeated various industries, including hydraulic systems. As global buyers seek eco-friendly hydraulic pump options, manufacturers are responding by developing products that not only perform efficiently but also minimize environmental impact. The focus on using renewable materials and innovative designs has led to a new wave of sustainable pumps that cater to eco-conscious consumers.

**Tips:** When exploring hydraulic pump options, consider those designed with energy efficiency in mind. Pumps that utilize variable speed drives can significantly reduce energy consumption, leading to a lower carbon footprint. Additionally, look for products made from recyclable materials, as they contribute to a circular economy.

Furthermore, the adoption of biodegradable hydraulic fluids in conjunction with sustainable pump designs can improve the overall environmental performance of hydraulic systems. Such fluids minimize the risk of contamination and enhance safety, making them a worthwhile investment for environmentally responsible businesses.

**Tips:** Always check for certifications that indicate sustainability, such as Energy Star or ISO 14001, which can provide assurance of a product's eco-friendly credentials. Engage with suppliers who prioritize sustainable practices and can offer insights into their production processes to ensure your choices support a greener future.

Cost-Effectiveness: Balancing Quality and Affordability in Pump Choices

In the quest for cost-effective hydraulic pump solutions, global buyers are increasingly balancing quality and affordability. In the dynamic market landscape, it is essential to explore alternatives that offer both performance and value. The right choice in hydraulic pumps can greatly impact operational efficiency and overall project costs.

Recent trends indicate a growing demand for easily installable and portable options, as seen in the portable swimming pool market, which is projected to reach approximately $1.2 billion in 2023. With a compound annual growth rate of 6.3% from 2024 to 2032, this segment highlights the consumer preference for convenience without compromising quality. Just as portable pools offer flexibility and enjoyment, the right hydraulic pump can provide the same benefits—delivering reliability and performance while remaining budget-friendly.

As global buyers navigate the myriad options available, it becomes critical to examine different manufacturers and models that meet their requirements for sustainability, efficiency, and adaptability. By prioritizing quality alternatives, buyers can ensure that they make informed decisions that enhance their operations without breaking the bank.

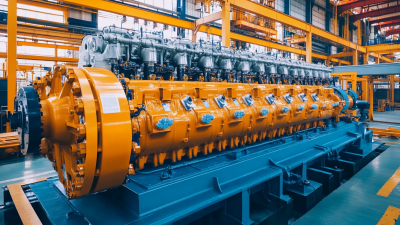

The Role of Automation in Enhancing Hydraulic Pump Performance

As the demand for high-performance hydraulic pumps continues to grow, the role of automation in enhancing their efficiency cannot be overstated. Integrating automated systems into hydraulic pump operations not only boosts reliability but also reduces human error and maintenance costs. Automation facilitates real-time monitoring and adjustment of pump performance, ensuring optimal functionality under varying loads and environmental conditions.

Tips: When considering automation, select systems that allow for easy integration with existing pump configurations. Look for automation solutions that provide data analytics tools to monitor performance metrics over time, helping you make informed decisions about maintenance and upgrades.

Furthermore, automated hydraulic pumps can significantly improve energy efficiency. Smart technologies enable pumps to operate at their best under changing conditions, minimizing energy waste. By harnessing automated control systems, companies can achieve significant cost savings while also reducing their carbon footprint.

Tips: Regularly update your automation software and ensure compatibility with your hydraulic systems. Training your team to understand and leverage these automated technologies is crucial for maximizing the performance and lifespan of your hydraulic pumps.

Navigating Global Market Trends: Buyer Preferences in Pump Selection

In the evolving landscape of global pump markets, buyer preferences are significantly influenced by trends in regional utility sectors.

The North American utility pump market is projected to reach a valuation of

$2.14 billion in 2024, with expectations of growth to

$2.23 billion in 2025 and

$3.04 billion by 2032. This steady increase highlights a growing demand for quality alternatives to traditional hydraulic pumps, propelled by innovations and shifts in consumer requirements.

Meanwhile, the secondary market for bulk carriers, particularly those built in Japan, is experiencing an exceptional surge in demand.

Market analysts attribute this trend to recent developments such as the U.S. decision to impose port fees on vessels constructed in China.

As a result, buyers are increasingly gravitating toward Japanese-built ships, which are perceived to offer greater reliability and value.

This shift not only underscores the changing dynamics of the maritime sector but also reflects the broader trend of buyers seeking

quality and assurance in their procurement choices on a global scale.