Revolutionizing 2025: The Rise of the Best Hydraulic Engine in Future Manufacturing

In the rapidly evolving landscape of manufacturing, the year 2025 stands poised to witness a transformative shift driven by the innovative capabilities of the Hydraulic Engine. With the global hydraulic market projected to reach approximately $54.5 billion by 2025, according to a recent market analysis, the adoption of advanced hydraulic technologies is becoming imperative for manufacturers striving for efficiency and sustainability. This surge in hydraulic engine implementation is not merely a trend; it reflects a fundamental change in how industries operate, promising enhanced productivity and reduced operational costs. Moreover, "中国智造,全球热销,品质保证" represents a commitment to high-quality manufacturing that leverages hydraulic innovations, positioning Chinese manufacturers at the forefront of this global revolution. As we delve deeper into the capabilities and advantages of hydraulic engines, it becomes clear that these systems will be crucial in redefining the standards of modern manufacturing.

Identifying Quality Hydraulic Engine Suppliers: Key Metrics and Considerations

In the evolving landscape of manufacturing, the selection of quality hydraulic engine suppliers has become paramount. According to a recent report by MarketsandMarkets, the global hydraulic equipment market is projected to grow from $43.5 billion in 2020 to $67.2 billion by 2026, with a CAGR of 7.8%. This growth underscores the importance of suppliers who not only meet current demand but also innovate in hydraulic solutions. When identifying potential suppliers, manufacturers should consider metrics such as design capabilities, adherence to industry standards, and certifications like ISO 9001, which indicates a commitment to quality management systems.

Furthermore, analyzing the supplier's track record for reliability is critical. A report by Grand View Research reveals that 75% of manufacturers experience delays due to supply chain disruptions, often linked to subpar supplier performance. Thus, evaluating a supplier's customer feedback and historical performance can significantly mitigate risks in production timelines. Additionally, assessing their technological advancements and research capacities can help in determining their ability to provide cutting-edge hydraulic engines that meet the challenges of future manufacturing needs. By focusing on these metrics, manufacturers can position themselves for success in a market that demands both efficiency and innovation.

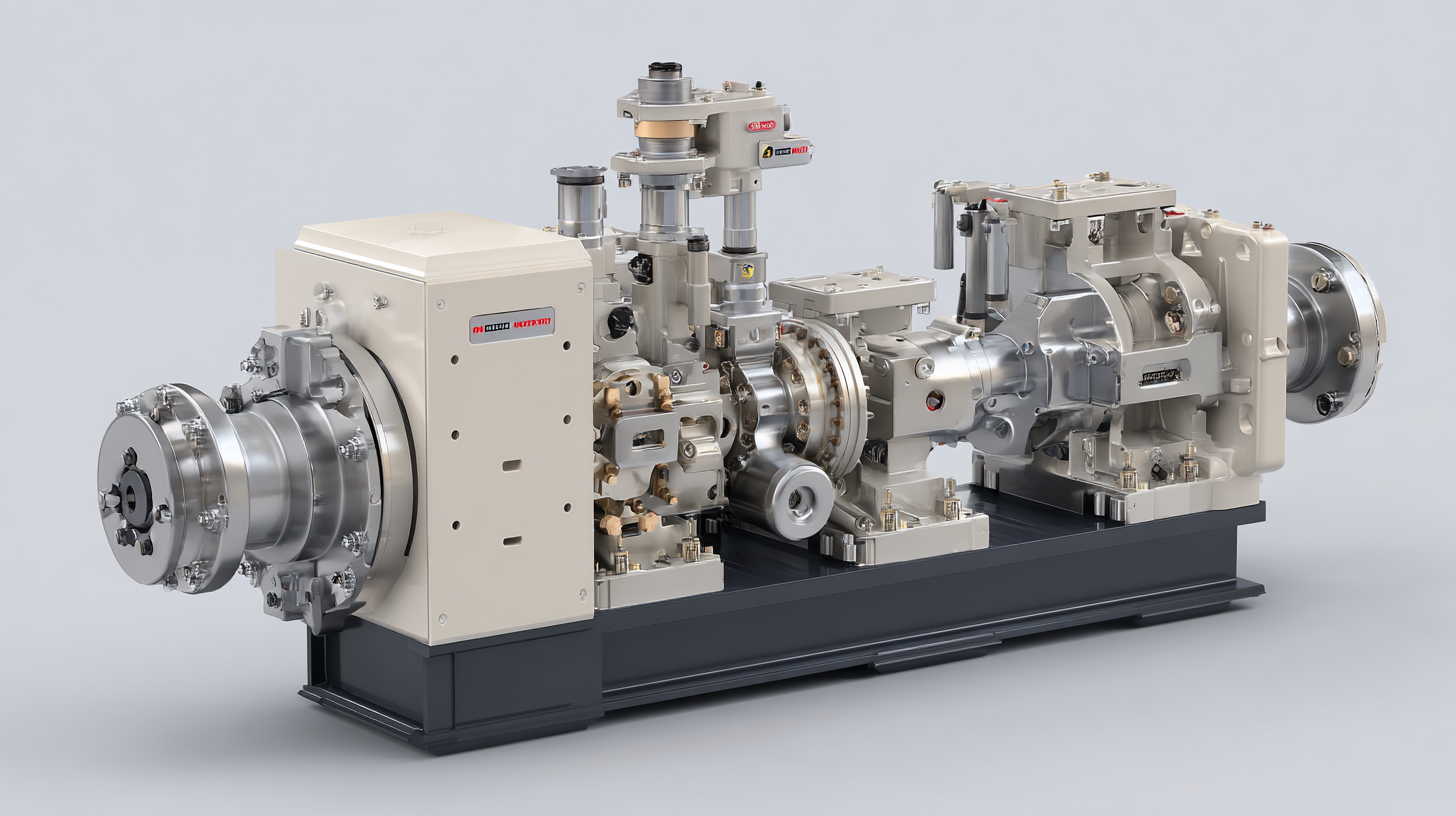

Assessing Supplier Capabilities: Performance Data and Manufacturing Expertise

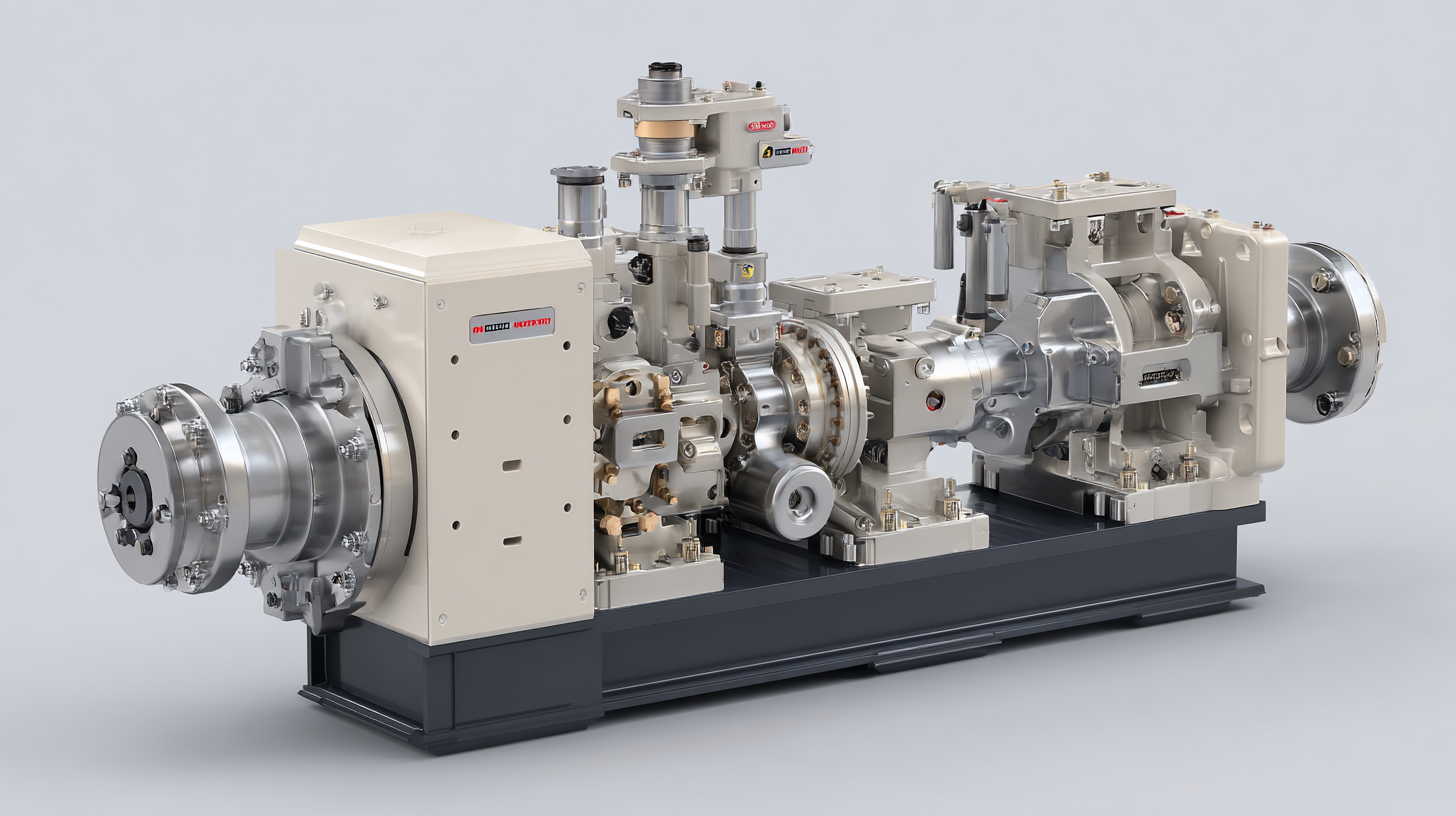

In the fast-evolving landscape of manufacturing, the emergence of advanced hydraulic engines is set to redefine operational efficiency and performance. As industries gear up for 2025, assessing supplier capabilities becomes crucial. Performance data should extend beyond mere metrics; it must encompass reliability, responsiveness, and innovation. Manufacturers are advised to look for suppliers who not only provide robust performance figures but also demonstrate consistent improvement over time.

When evaluating potential suppliers, it can be beneficial to employ a structured approach. First, develop a checklist that includes both quantitative and qualitative criteria related to their manufacturing expertise. Tip: Engage in discussions about their design and implementation processes to gauge their adaptability to new technologies. Collaborating closely with suppliers who prioritize continuous learning and innovation can enhance your supply chain’s resilience.

Another important consideration is the alignment between your company's goals and the supplier's capabilities. Understanding their production methodologies and industry experience is essential. Tip: Request case studies or references from previous projects that illustrate their problem-solving approaches in real-world scenarios. This insight will not only help in making informed decisions but will also lead to successful partnerships that can withstand the challenges of the future manufacturing landscape.

Supply Chain Reliability in 2025: Ensuring Consistency in Hydraulic Engine Production

In 2025, the manufacturing landscape will witness a significant transformation driven by advancements in hydraulic engine technology. A key component of this evolution will be the reliability of supply chains, crucial for ensuring consistent production of these engines. According to a report by McKinsey, nearly 75% of manufacturers have identified supply chain robustness as a critical factor in maintaining their competitive edge. Ensuring that hydraulic engine components are readily available requires a strategic approach to sourcing, production, and logistics.

The rise of the best hydraulic engines will depend not only on technological innovations but also on resilient supply chain strategies. As highlighted in a recent survey by PwC, 50% of manufacturers plan to invest heavily in automated supply chain solutions within the next two years. This investment aims to optimize inventory management and enhance visibility across the supply chain, effectively mitigating risks associated with disruptions. Furthermore, the integration of AI-driven analytics will allow manufacturers to forecast demand more accurately, thereby ensuring the timely production of hydraulic engines that meet the evolving needs of industries in 2025.

Evaluating Innovative Technologies: The Role of R&D in Hydraulic Engine Supply

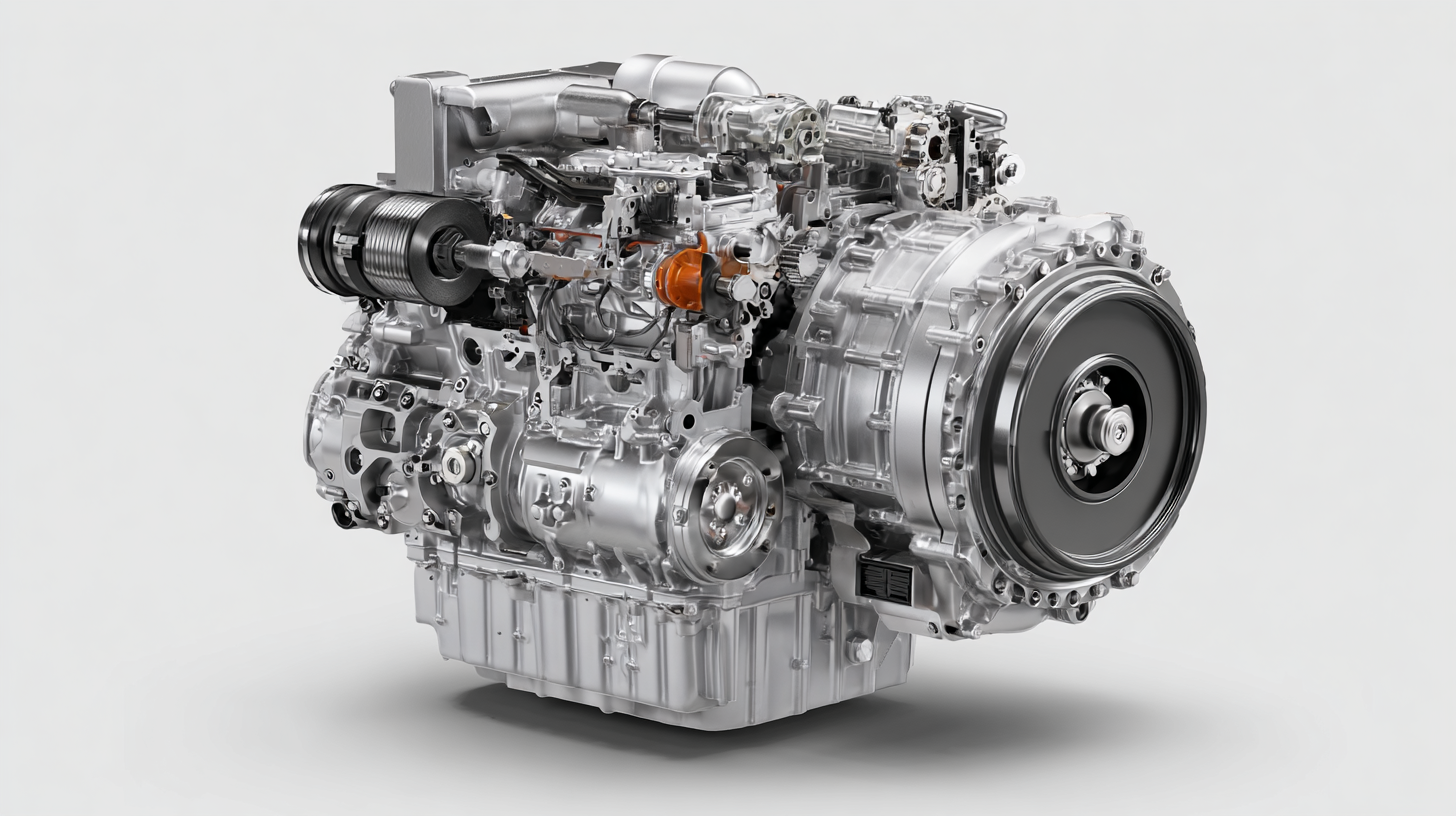

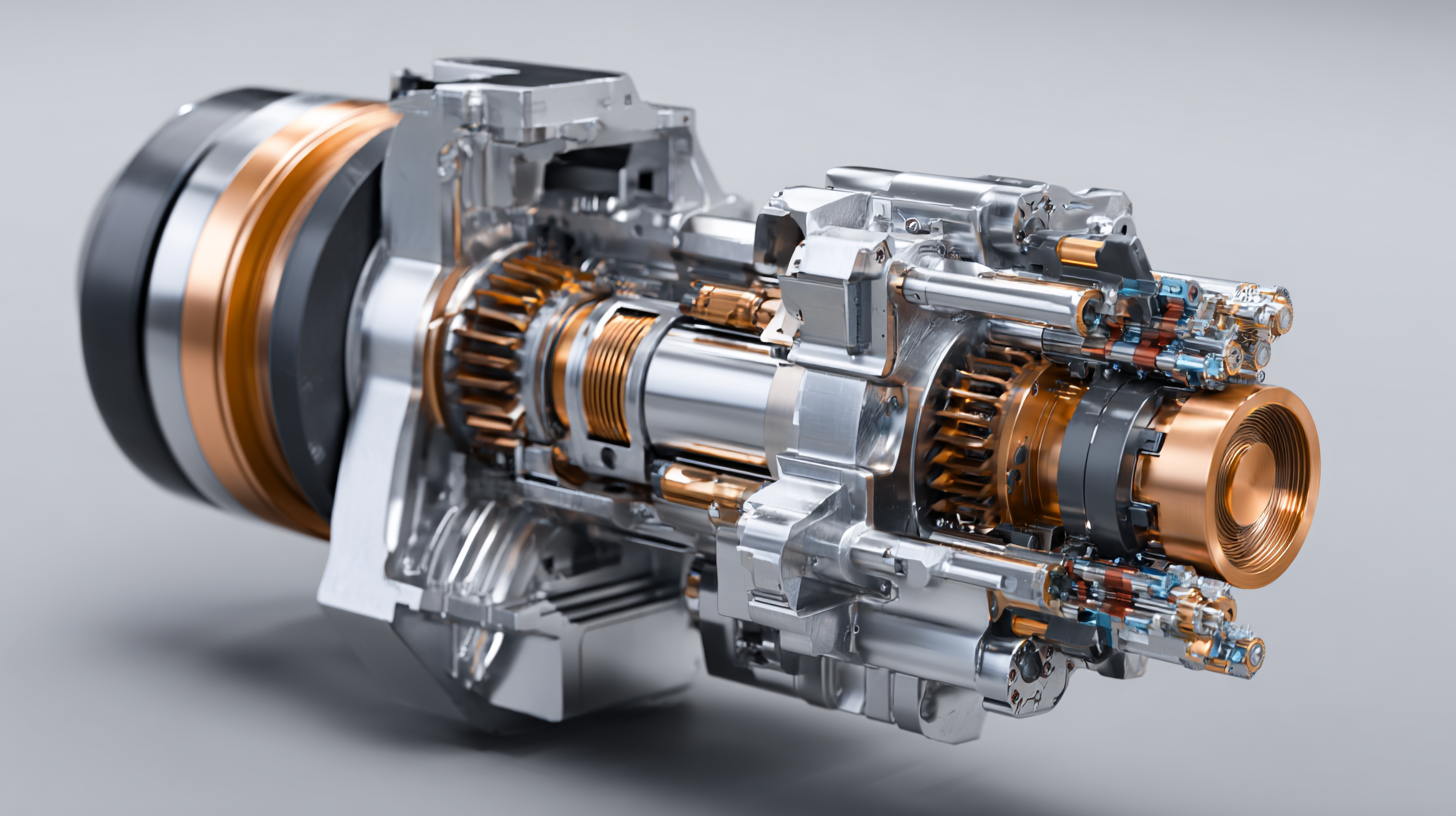

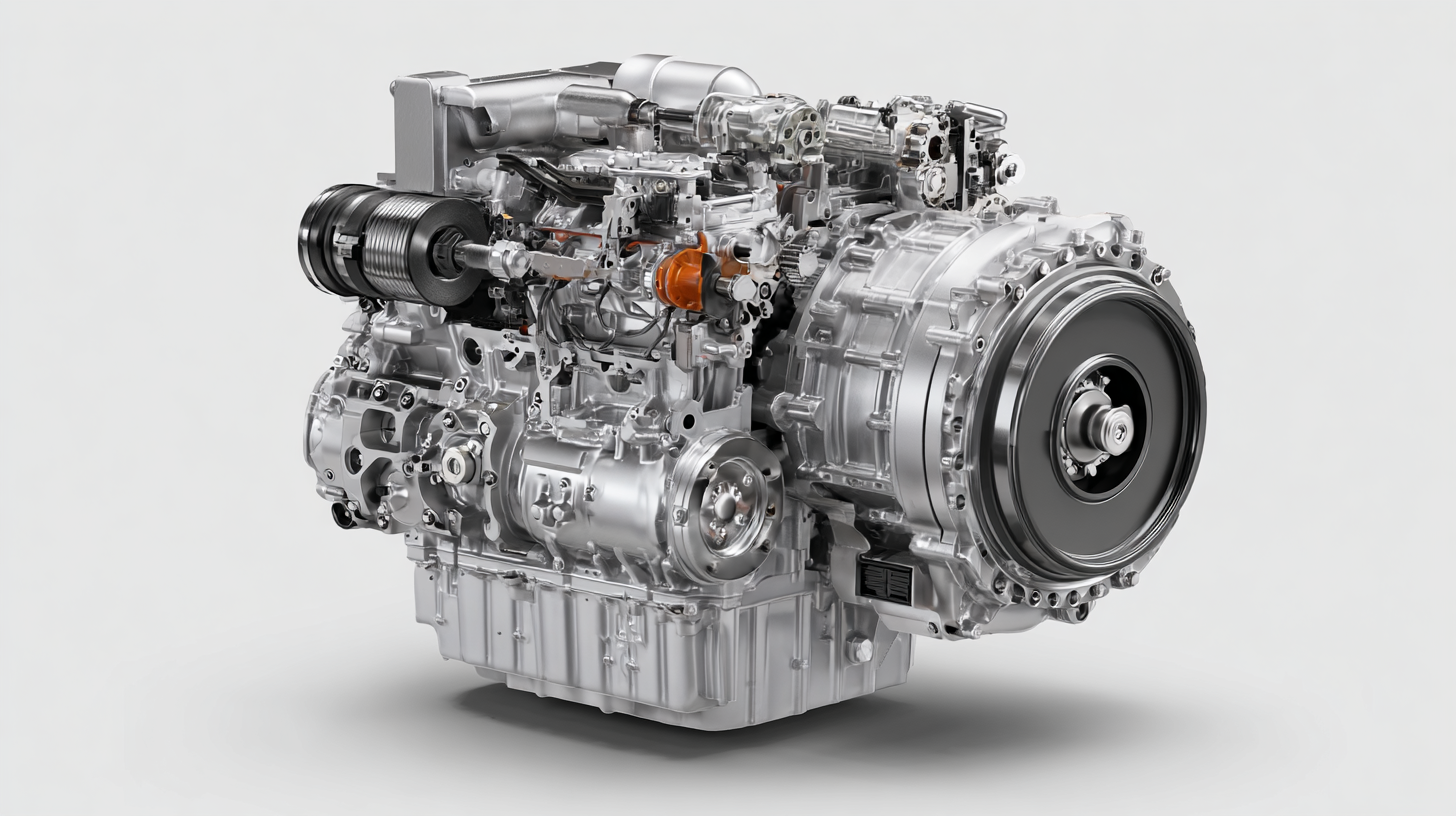

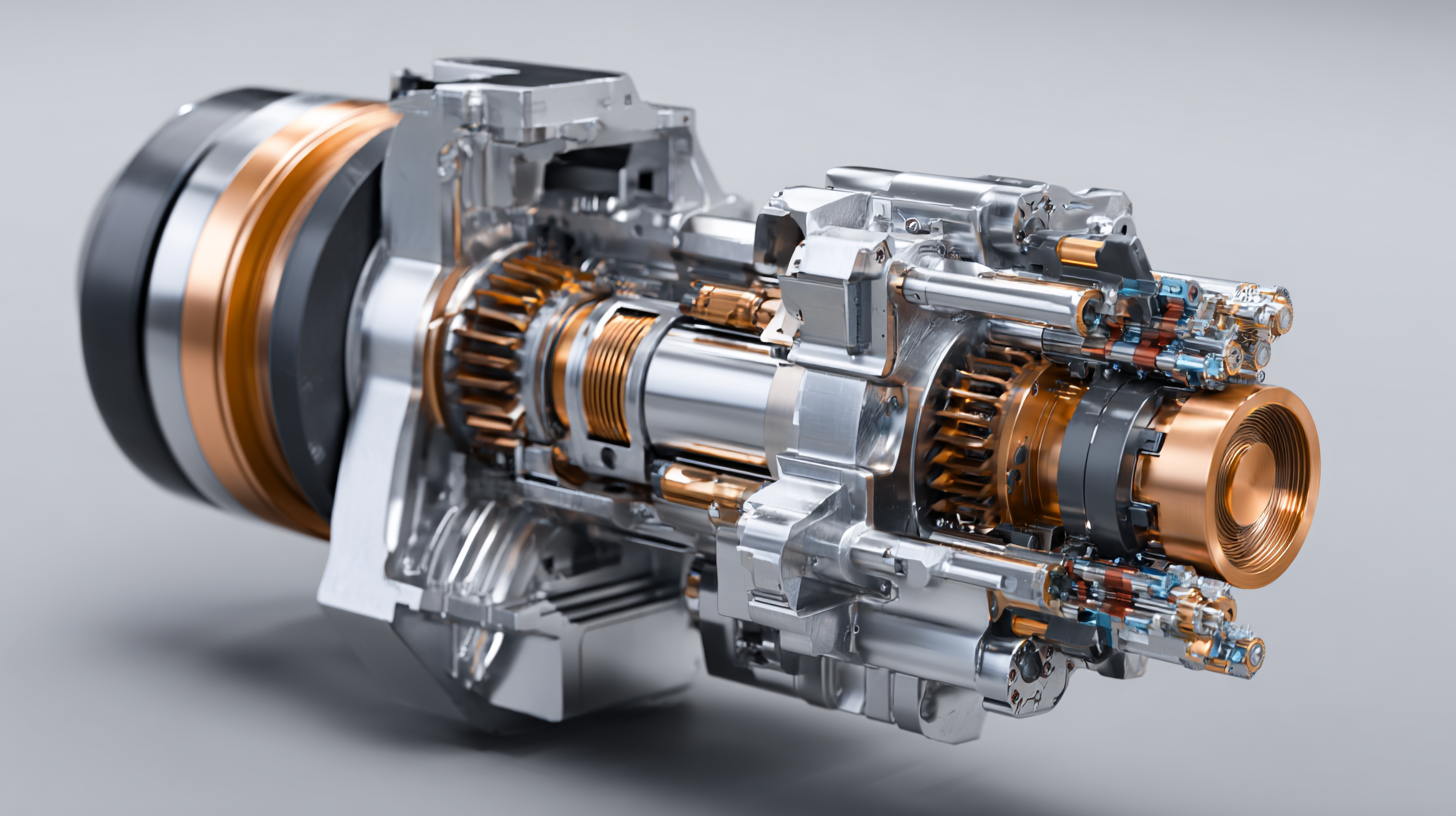

As we move toward 2025, the hydraulic engine is poised to become a cornerstone of future manufacturing. At the heart of this transformation is the commitment to research and development (R&D), which plays a crucial role in identifying innovative technologies that elevate hydraulic systems beyond traditional applications. As industries seek more efficient and sustainable solutions, R&D acts as a catalyst for breakthroughs that enhance performance, reliability, and energy efficiency.

The collaborative efforts between engineers, researchers, and manufacturers are essential in pushing the boundaries of hydraulic engine technology. Innovations such as advanced materials, smart sensors, and integrated control systems are emerging from rigorous research initiatives. These advancements not only improve the functionalities of hydraulic engines but also align with global goals of sustainability by reducing waste and energy consumption. In the race to develop the most efficient hydraulic engines, R&D stands as a beacon guiding the industry toward a more productive and eco-friendly future.

Global Market Trends: Sourcing Hydraulic Engines from Emerging Economies

The global hydraulic engine market is poised for significant growth, particularly as manufacturing processes evolve in response to the demands of emerging economies. With the hydraulic cylinder market valued at approximately $14.3 billion in 2021 and projected to reach $18.3 billion by 2027, at a CAGR of 4.4%, there is a clear trend toward increasing reliance on hydraulic systems in manufacturing processes. As industry players source hydraulic engines from these developing markets, they can tap into cost-effective production while benefiting from local advancements in technology.

Moreover, the transportation sector's burgeoning growth, highlighted by the automotive sector's projected market increase to $24.3 billion by 2024, with an impressive CAGR of 8.9% through 2034, illustrates the vital role of hydraulic engines in future manufacturing frameworks. This upward trajectory is further fueled by innovations in automotive technologies and the rising demand for sustainable practices, underscoring the integral role of hydraulics in modern manufacturing. As countries like China lead with advanced industrial capabilities, there is a notable shift toward a more collaborative global economy that prioritizes efficient hydraulic solutions for the future.

Revolutionizing 2025: The Rise of the Best Hydraulic Engine in Future Manufacturing - Global Market Trends

| Region |

Market Size (USD Million) |

Growth Rate (%) |

Key Application Sectors |

Emerging Economies |

| North America |

5000 |

4.5 |

Construction, Agriculture |

Mexico, Canada |

| Europe |

4500 |

3.8 |

Automotive, Industrial |

Poland, Hungary |

| Asia-Pacific |

6000 |

5.5 |

Manufacturing, Energy |

India, China |

| Latin America |

1500 |

4.0 |

Mining, Agriculture |

Brazil, Argentina |

| Middle East & Africa |

1000 |

3.0 |

Construction, Oil & Gas |

UAE, South Africa |