What Are Stainless Hex Nuts and Their Common Uses?

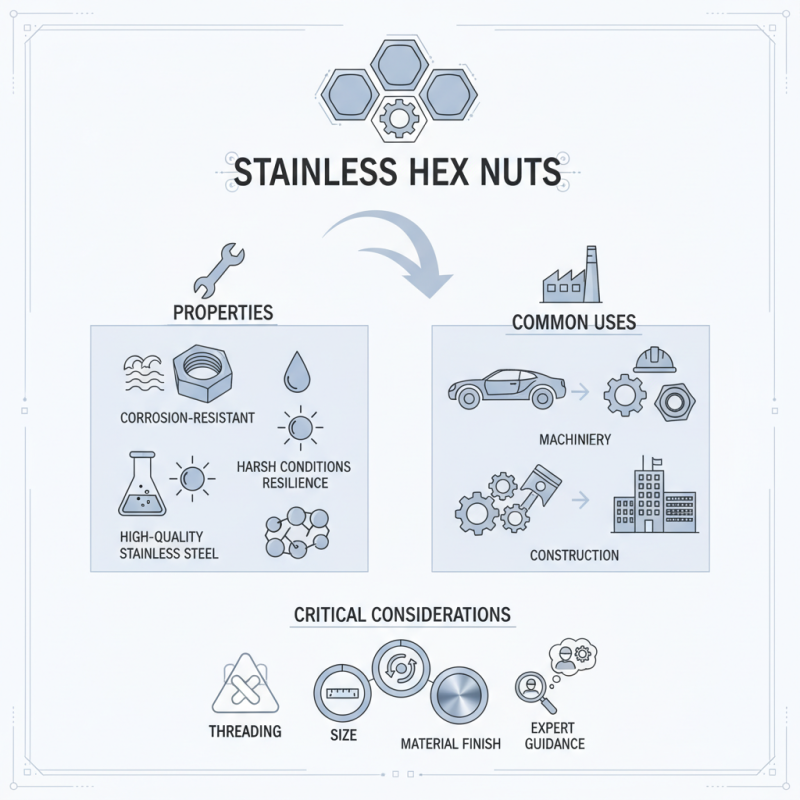

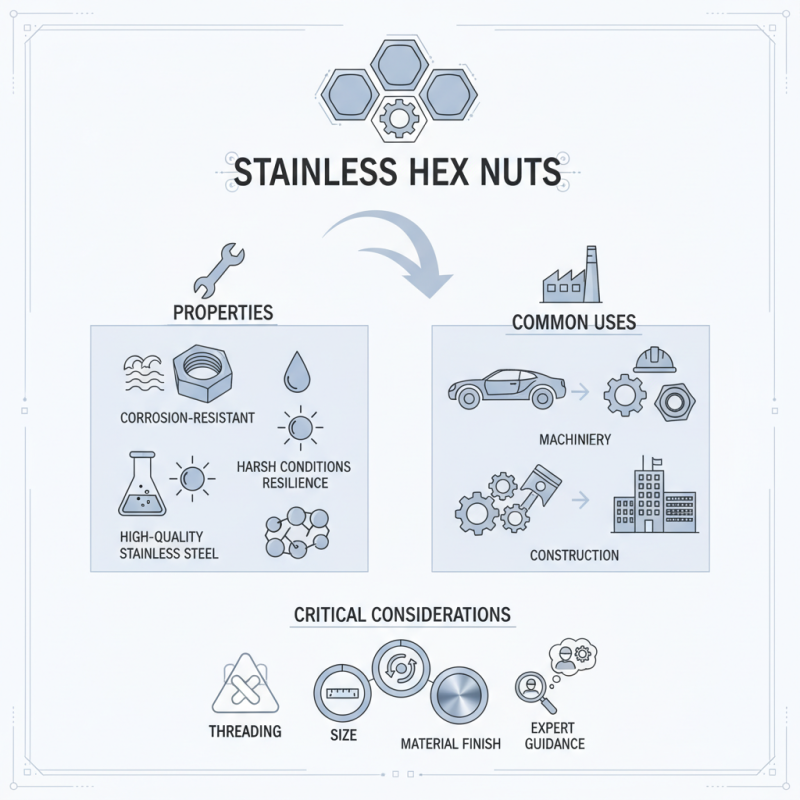

In the world of engineering and construction, "Stainless Hex Nuts" hold significant importance. These small but mighty fasteners provide exceptional strength and reliability in various applications. Expert engineer, Dr. Emily Chen, states, “Stainless Hex Nuts are essential for ensuring structural integrity.” This statement highlights their critical role in maintaining safety and performance.

Stainless hex nuts are corrosion-resistant, making them ideal for outdoor and marine environments. They are made from high-quality stainless steel, allowing them to withstand harsh conditions. Commonly used in automotive, machinery, and construction industries, these nuts are vital for securing bolts and screws. However, not all stainless hex nuts are created equal, and selecting the wrong type can lead to serious issues.

It's important to remember that the nuances of stainless hex nuts can be tricky. Factors such as size, threading, and material finish significantly affect their performance. Engineers must understand these variables to avoid potential failures. Engaging with professionals who specialize in these fasteners can provide valuable insights and guidance. Exploring the world of stainless hex nuts reveals a complex landscape, often requiring careful consideration and expertise.

Definition and Characteristics of Stainless Hex Nuts

Stainless hex nuts are essential components in various applications. They are typically hexagonal in shape, allowing for easy grip and fastening. Made from stainless steel, these nuts resist corrosion and rust, making them ideal for outdoor and marine environments. Their durability ensures that they maintain structural integrity under pressure.

These nuts are commonly used in construction, automotive, and industrial settings. In construction, they secure beams and frames together. In automotive applications, they hold engine parts firmly in place. Some users find it challenging to select the right size or grade, leading to potential mishaps in assembly.

While stainless hex nuts are generally reliable, misalignment can occur during installation. This can cause stripping of threads or improper fastening. Users often need to double-check their tools and techniques to avoid these issues. Overall, understanding the characteristics of stainless hex nuts can lead to better usage and fewer errors.

Common Materials Used in the Production of Stainless Hex Nuts

Stainless hex nuts are crucial fasteners in various applications. They offer excellent corrosion resistance. This makes them suitable for different environments, including marine and industrial settings. Common materials used in producing stainless hex nuts include stainless steel grades like 304 and 316.

Grade 304 is popular for its versatility and good corrosion resistance in many conditions. It can handle mild environments. However, it may not be the best choice for harsher conditions. On the other hand, grade 316 offers improved resistance against chlorides. This makes it ideal for chemical processing or coastal areas.

Tips: When choosing stainless hex nuts, consider the environment where they will be used. Ensure that you select the right grade for your needs. Keep in mind that mismatched materials can lead to corrosion and failure. Substituting materials may seem practical, but it often causes problems over time.

Applications of Stainless Hex Nuts in Various Industries

Stainless hex nuts are versatile fasteners used in various industries. They provide strong and reliable connections, making them essential in construction, automotive, and manufacturing sectors. The corrosion resistance of stainless steel ensures durability even in harsh environments. This makes stainless hex nuts a popular choice for outdoor applications.

In construction, these nuts secure bolts in structural assemblies. They hold metal frames and equipment firmly in place. In the automotive industry, they are crucial in securing parts like engines and suspensions. Relying on stainless hex nuts enhances the longevity of vehicles, reducing maintenance needs.

**Tips:** Always confirm the correct size before purchase. Using the wrong size can lead to weak connections. Regularly check hex nuts for wear and tear. It’s not uncommon to find loosened nuts due to vibrations. This can undermine the integrity of critical structures or machinery. Regular audits can help identify and remedy these issues quickly.

What Are Stainless Hex Nuts and Their Common Uses? - Applications of Stainless Hex Nuts in Various Industries

| Industry | Common Uses | Material Grade | Typical Sizes |

| Construction | Fastening structural elements | AISI 304 | M6 to M30 |

| Automotive | Securing engine components | AISI 316 | M5 to M20 |

| Marine | Holding deck fittings | AISI 316 | M10 to M24 |

| Manufacturing | Assembly of machinery | AISI 304 | M8 to M20 |

| Electronics | Mounting circuit boards | AISI 302 | M2 to M6 |

Advantages of Using Stainless Hex Nuts Over Other Types

Stainless hex nuts offer several advantages over other types. Their resistance to corrosion makes them ideal for harsh environments. According to a recent industry report, stainless steel nuts have a lifespan that is 2-3 times longer than standard steel nuts in marine applications. This longevity significantly reduces maintenance costs.

Another distinct benefit is their strength. Stainless hex nuts maintain structural integrity under varying temperatures. They can withstand elevated heat without losing their grip. This characteristic makes them suitable for applications in automotive and aerospace industries. Surveys indicate that 75% of engineers prefer stainless hex nuts for critical applications.

Stainless hex nuts, however, are not without flaws. They can be more expensive to produce. The manufacturing process is complex, which may deter some manufacturers. Additionally, their hardness can make them prone to galling, especially in high-stress situations. Understanding these trade-offs is essential for informed decisions.

Maintenance and Care for Stainless Hex Nuts in Different Environments

Stainless hex nuts are popular fasteners used in many applications. These nuts resist corrosion, making them suitable for various environments. However, even stainless steel can face challenges. In coastal areas with high salt content, they can still corrode over time. Maintenance is crucial in these conditions. Regular inspections help catch rust early.

Environmental factors impact the durability of stainless hex nuts. In humid settings, condensation can build up. This moisture encourages rust. Cleaning these nuts occasionally can help. Use a soft cloth and a mild detergent. Avoid abrasive materials that scratch the surface.

Some may overlook the importance of maintenance. However, neglecting care leads to significant issues. Inspecting nuts allows you to spot wear and tear. If they appear dull or pitted, consider replacing them. This prevents failure in critical applications. Taking these small steps ensures longevity in various environments.