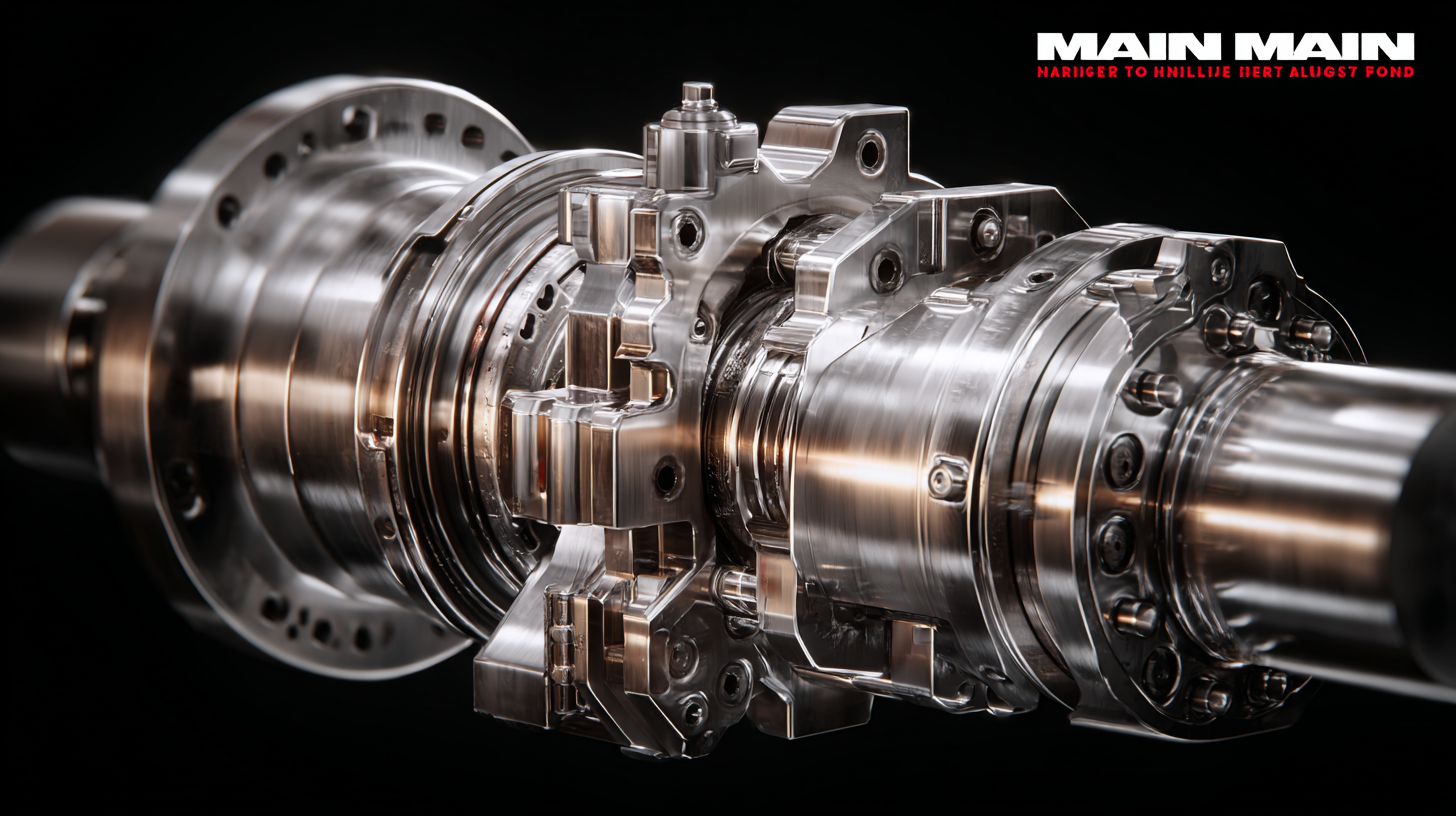

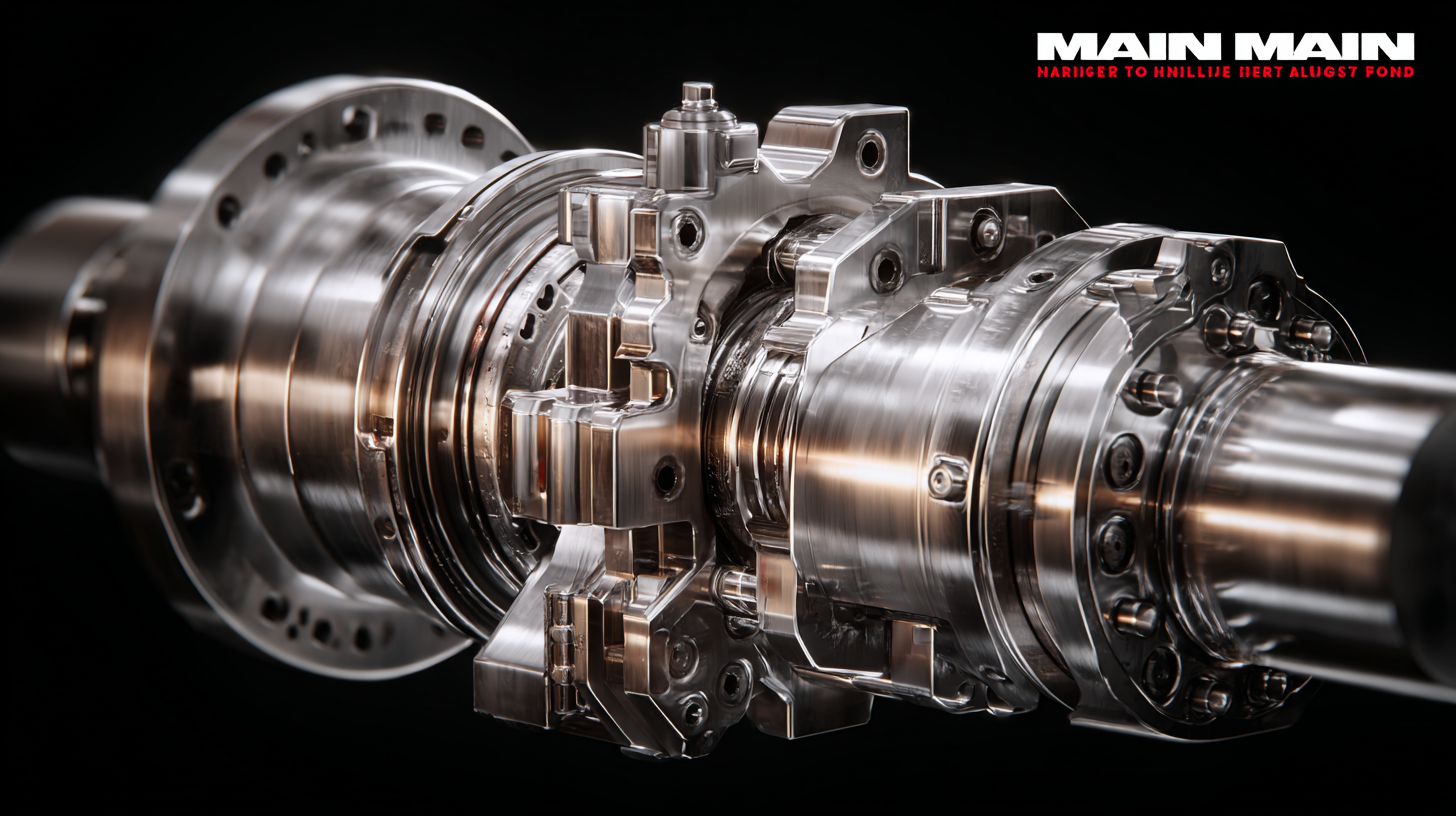

Exploring Superior Alternatives to the Best Main Hydraulic Pump for Global Buyers

In the highly competitive hydraulic equipment market, the selection of the Main Hydraulic Pump is critical for global buyers seeking optimal performance and reliability. According to a recent report by Research and Markets, the global hydraulic pump market is projected to reach $12.53 billion by 2027, driven by increasing demand across various sectors, including construction, agriculture, and manufacturing. As innovation continues to shape this landscape, buyers are encouraged to explore superior alternatives that not only meet their operational needs but also offer enhanced efficiency and reduced maintenance costs. This tutorial aims to shed light on the best options available, examining both established and emerging technologies, and ultimately guiding global buyers toward making informed decisions in a market where the right Main Hydraulic Pump can significantly impact productivity and profitability.

Exploring Upgrades: Comparing After-Sales Service Benefits and Repair Costs in Hydraulic Pumps

When it comes to hydraulic pumps, buyers often focus on performance metrics and initial purchase costs, overlooking crucial aspects like after-sales service and repair costs. These elements can significantly impact the long-term value of a pump. A robust after-sales service ensures that regular maintenance and emergency repairs are handled efficiently, minimizing downtime. Buyers should choose a supplier that offers comprehensive support, including access to spare parts, expert technicians, and timely service interventions.

Tips: When assessing after-sales service, always check for customer reviews and testimonials. Research the supplier's reputation for responsiveness and reliability. Additionally, request details about warranty coverage and the potential for extended service agreements, as these can provide peace of mind and protect against unexpected repair costs.

Comparing repair costs across different brands and models is another essential factor in making an informed decision. Some pumps may have lower upfront costs but could incur higher maintenance expenses later. It's advisable to obtain quotes from service providers for common repairs associated with the models under consideration. This proactive approach not only aids in budget planning but also ensures that buyers select a hydraulic pump that offers the best balance of performance and cost-effectiveness over time.

Key Metrics for Evaluating the Best Main Hydraulic Pump Alternatives Worldwide

When assessing alternatives to the best main hydraulic pumps, it’s essential to consider key metrics that define their effectiveness and sustainability in various applications. This evaluation must encompass factors like efficiency ratings, maintenance needs, and adaptability to changing technology landscapes. As energy storage technologies evolve, the synergy between hydraulic systems and renewable sources becomes increasingly important. Hydraulic pumps must not only perform optimally but also integrate seamlessly with energy-saving infrastructures.

Moreover, evaluating the global economic and environmental impacts of hydraulic pump alternatives, particularly in the context of renewable energy, stands as a pivotal metric. Innovations in hydraulic technology can contribute to reducing carbon footprints and enhancing the performance of energy storage systems, driving the transition towards sustainable energy solutions. Buyers should prioritize alternatives that demonstrate resilience and adaptability in minimizing environmental effects while fulfilling operational requirements. The focus on sustainable practices in evaluating hydraulic pump options ensures long-term benefits for both users and the planet.

Understanding the Role of Digital Technology in Hydraulic Pump Efficiency and Maintenance

Digital technology is transforming the landscape of hydraulic pump efficiency and maintenance, allowing for enhanced performance and longevity in operations. According to a recent report by the International Society for Automation, the integration of IoT (Internet of Things) technology in hydraulic systems can increase efficiency by up to 30%. Real-time data analytics enables operators to monitor pump performance continuously, identify potential issues before they lead to failures, and optimize maintenance schedules.

Furthermore, predictive maintenance powered by AI algorithms is rapidly gaining traction in the hydraulic sector. A study from McKinsey highlights that predictive maintenance can reduce unplanned downtime by up to 50%. By leveraging machine learning models, companies can accurately forecast when a hydraulic pump will require servicing, thus improving both productivity and cost-efficiency. As global buyers seek superior alternatives to traditional hydraulic pumps, the role of digital technology will undoubtedly be a key factor in their decision-making processes, driving a shift towards more proactive and data-driven maintenance strategies.

Proven Strategies for Reducing Long-Term Operating Costs of Hydraulic Systems

Hydraulic systems are indispensable in various industrial applications, and managing their long-term operating costs is critical for global buyers. According to a recent report by MarketsandMarkets, the hydraulic systems market is projected to reach $53.6 billion by 2025, highlighting the growing reliance on these systems across multiple sectors. To optimize performance and reduce costs, it is essential to explore superior alternatives to traditional main hydraulic pumps, which can consume significant energy over time.

**Tip:** Regular maintenance and timely replacements of hydraulic components can prevent unexpected failures. Implement a schedule for routine inspections to identify wear and tear, which, according to the International Fluid Power Society, can save operators up to 30% in costs related to downtime and emergency repairs.

Moreover, investing in high-efficiency hydraulic pumps can lead to substantial savings in energy consumption. Research by the Hydraulic Institute indicates that upgrading to energy-efficient models can reduce operating costs by as much as 20%. This not only minimizes the carbon footprint of industrial operations but also accelerates return on investment through lowered utility bills.

**Tip:** Consider transitioning to variable displacement pumps that can adjust output based on demand, further enhancing efficiency and slashing operational costs. By incorporating such innovative solutions, companies can ensure their hydraulic systems perform optimally while keeping long-term expenses in check.

Exploring Superior Alternatives to the Best Main Hydraulic Pump for Global Buyers - Proven Strategies for Reducing Long-Term Operating Costs of Hydraulic Systems

| Alternative Pump Type |

Efficiency Rating (%) |

Average Lifespan (Years) |

Estimated Energy Savings (%) |

Average Cost Reduction (%) |

| Variable Displacement Pump |

92 |

10 |

20 |

15 |

| Gear Pump |

85 |

8 |

15 |

10 |

| Axial Piston Pump |

90 |

12 |

18 |

12 |

| Vane Pump |

80 |

6 |

10 |

5 |

| Gearbox Integrated Pump |

88 |

9 |

17 |

8 |

Insights into Global Market Trends: The Rise of Advanced Hydraulic Pump Solutions

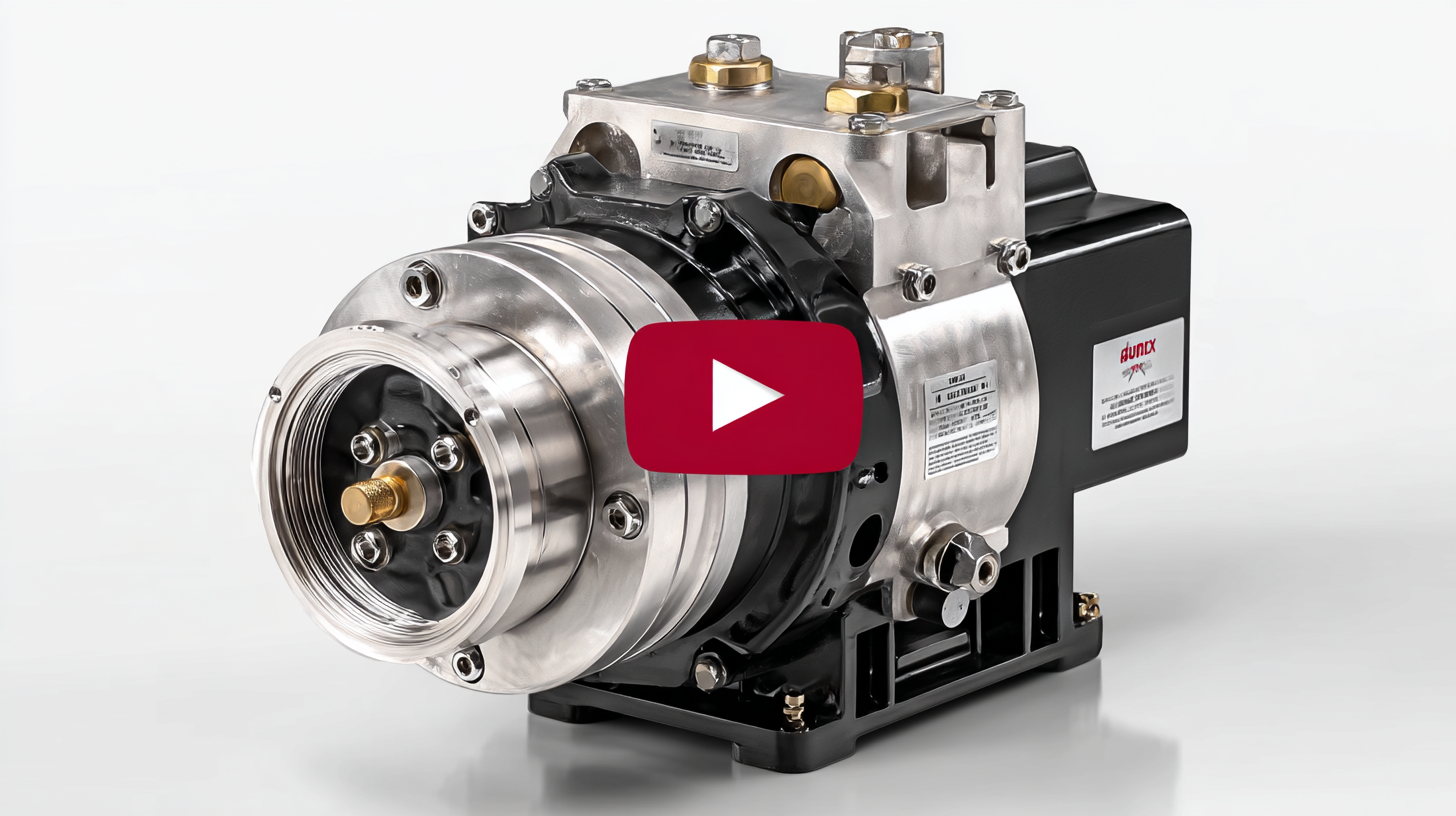

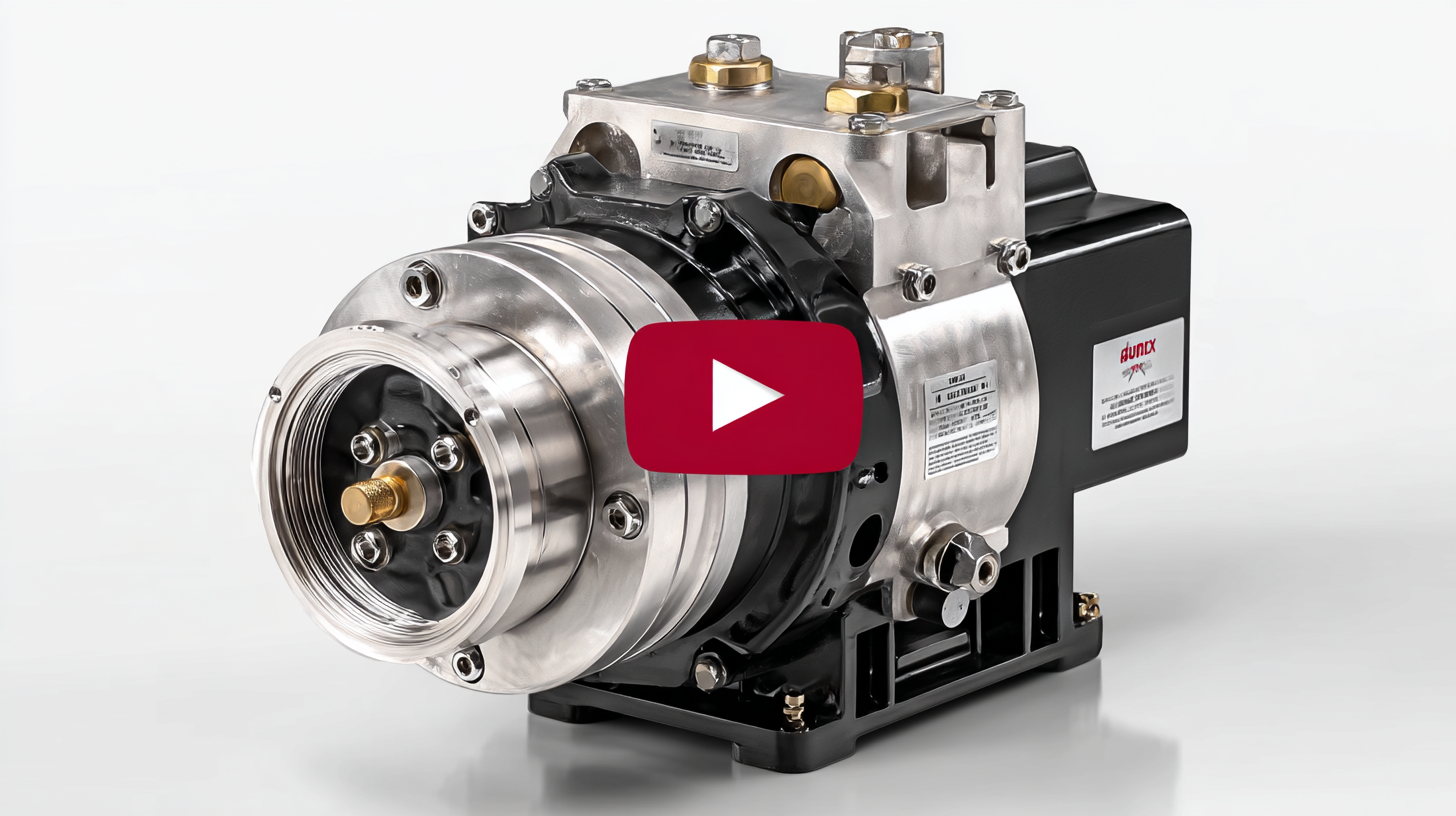

The hydraulic pump market is witnessing transformative growth, driven by the increasing demand for advanced solutions across various industries. Key trends highlight a shift towards more efficient and sustainable hydraulic pump systems that not only enhance operational performance but also reduce environmental impact. Global buyers are now seeking alternatives that incorporate cutting-edge technology, such as IoT integration and smart diagnostics, which enable predictive maintenance and remote monitoring.

As manufacturers innovate, features like energy efficiency and compact design are becoming standard. The rise of electric and hybrid hydraulic pumps signifies a paradigm shift as companies aim to meet stricter regulatory requirements and consumer preferences for greener alternatives. This evolution in product offerings is shaping a competitive landscape where adaptability and innovation play crucial roles, allowing buyers to explore superior options tailored to their specific needs. With the ongoing advancements, the hydraulic pump industry is set for a future that prioritizes both functionality and sustainability, ensuring that stakeholders invest wisely in their machinery.